Description

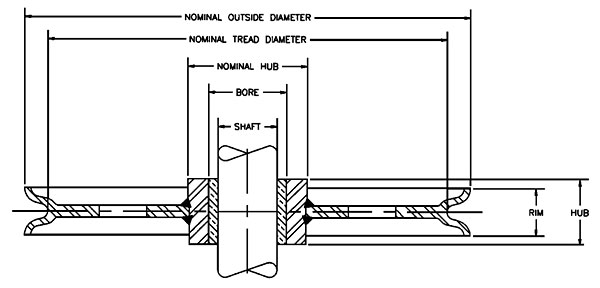

For special requirements or custom designed sheaves, furnish the following important information:

- Wireline Size

- Shaft Diameter

- Hub Diameter

- Bore Finished

- Nominal Outside Diameter

- Hub Width

- Rim Width

- Nominal Tread Diameter

- Other Special Requirements

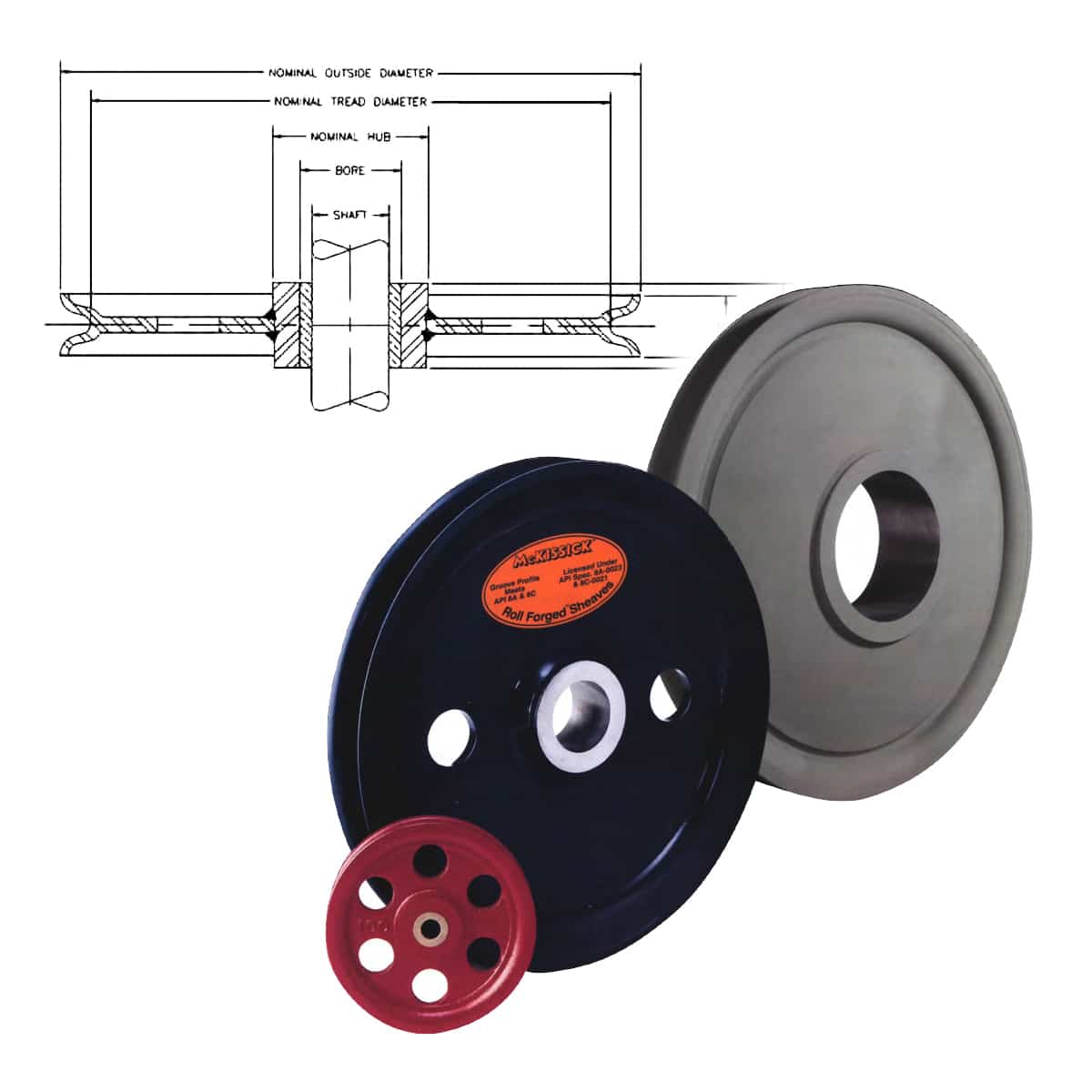

Roll Forged Sheave Features

Unique upset roll forging process provides a thicker groove section for extra strength.

- Stepped Hubs are precisely centered and mechanically locked in place.

- Wireline grooves on sheave diameters of 14″ and larger are flamed hardened for extra wear resistance.

- All sheaves have solid steel webs with holes for easy handling.

- Sheave weights can be made heavier or lighter than shown to fit your specific application.

- Sheaves available in sizes from 12″ – 72″, and wireline sizes from 3/8″ – 3″.

- For more information, ask for our special brochure describing the complete roll forging process.

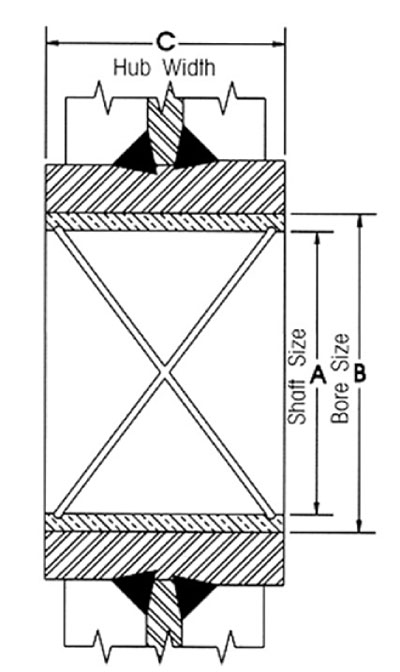

Sheave Bearing Application Information

Bronze Bushing:

Slow line speed, moderate load and moderate use,

- Maximum Bearing Pressure (BP): 4500 PSI

- Maximum Velocity at Bearing (BV): 1200 FPM

- Maximum Pressure Velocity Factor (PV): 55000

Formula for BP = Line Pull x Angle Factor ÷ Shaft Size x Hub Width

Plain Bore:

Very slow line speed, very infrequent use, low load.

Roller Bearing:

Faster line speeds, more frequent use, greater load.

Example:

Using a 14 in. sheave (917191) with a 4600 lb. line pull and a 80 degree angle between lines, determine maximum allowable line speed.

BP = 4600 lbs. (Line Pull) x 1.53 (Angle Factor) ÷ 1.50 (Hub Width) x 1.62 (Shaft Size) = 2896 PSI

BV = 55000 (PV Factor) ÷ 2896 (BP) = 19 FPM

Note: For underwater sheave applications, special bronze bushings are available.

Note: Consult the bearing manufacturer for applicable load.