Description

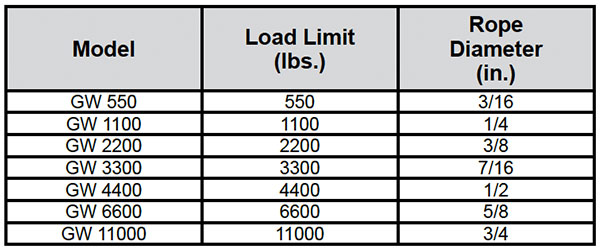

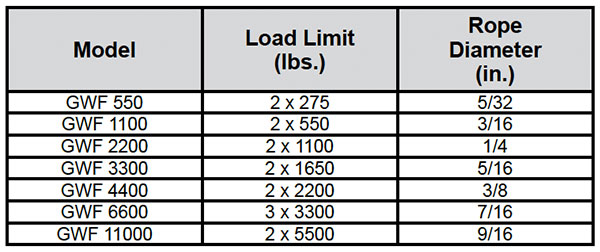

Worm Gear Wall Mount

Seven Rugged Sizes—Line pulls from 550 lbs. (250 kg) to 11,000 lbs. (5,000 kg). Higher-capacity models are equipped with two-speed gearing for ease in handling heavy loads.

Removable Handle—Prevents tampering if the operator must leave the winch under load.

Bearings—Effective use of needle roller bearings and bushings minimizes friction, ensures ease of operation, smooth running, increased life and minimum cranking effort.

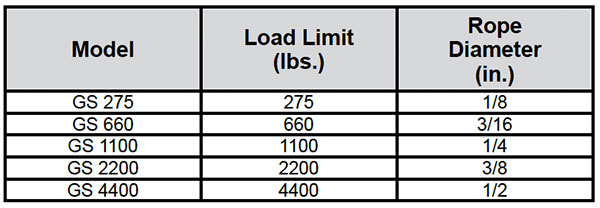

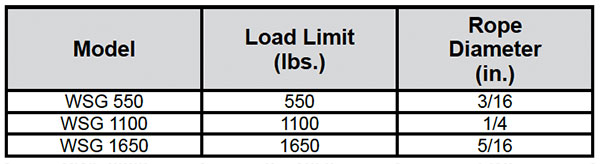

Wall Mount Spur Gear

High Efficiency—Leading-edge design reduces cranking effort.

Compact—Space-saver profile and fold-back crank are ideal for installation and operation in confined spaces.

Bearings—Effective use of needle roller bearings and bushings minimizes friction, ensures ease of operation, smooth running, increased life and minimum cranking effort.

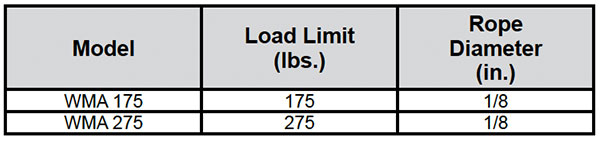

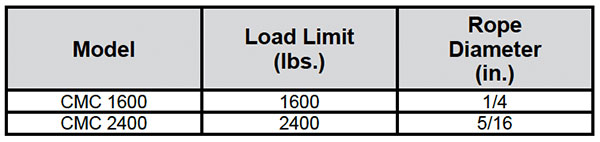

Aluminum Wall Mount

Lightweight, tough and easy to install.

Rope off at any angle.

Winch can be mounted in any position to allow the rope to come off at any angle.

Removable Handle—Prevents tampering if the operator must leave the winch under load.

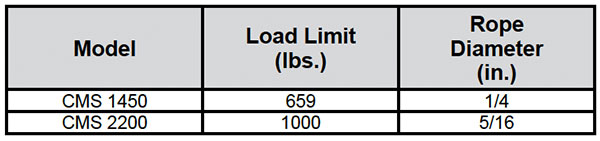

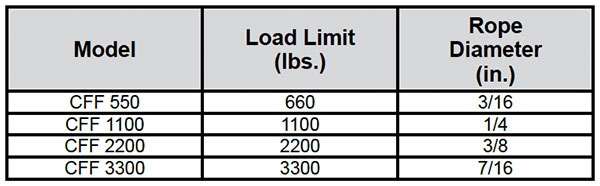

Stainless Steel Console Mount

Stainless Steel—Corrosion resistant in hostile environments and ideal in hygienic applications, such as food processing and pharmaceutical manufacturing.

Lightweight—For easy handling and installation.

High Efficiency—Leading-edge design reduces cranking effort. A minimum load of 110 lbs. is required for proper brake function.

Center Flange Wall Mount

Two ropes can be operated simultaneously. Drums have a center flange and rope anchors at each end.

* Note: Working Load Limit is per rope 1st layer.

Seven Rugged Sizes—Line pulls from 550 lbs. (250 kg) to 11,000 lbs. (5,000 kg).

Two Speeds—Higher-capacity models are equipped with two-speed gearing for ease in handling heavy loads. Effective use of needle roller bearings and bushings minimizes friction, ensures ease of operation, smooth running, increased life and minimum cranking effort.

Free Spooling

Aluminum—Lightweight for easy handling and installation.

Free Spooling—Ideal for getting rope out quickly under no-load conditions.

Totally Enclosed Gears—A sealed oil bath ensures constant lubrication and quiet operation.

Compact—Space-saver profile is ideal for installation and operation in confined spaces.

Worm Sealed Gear

High Rope-to-Drum Ratio—Rope life is substantially increased with drum diameters a minimum 20 times the diameter of the rope.

Designed for Heavy Duty Use—Line pulls range from 550 lbs. (250 kg) to 1650 lbs. (750 kg).

Removable Handle—Prevents tampering if the operator must leave the winch under load.

Controlled Free Fall

By simply pushing the handle back in the reverse direction, the winch will pay out at a controlled speed.

A centrifugal dynamic brake is incorporated to govern maximum speed and to prevent overspeeding of the load. This unique braking system also prevents the winch handle from recoiling.

High Rope-to-Drum Ratio—Rope life is substantially increased with drum diameters a minimum of 20 times the diameter of the rope.

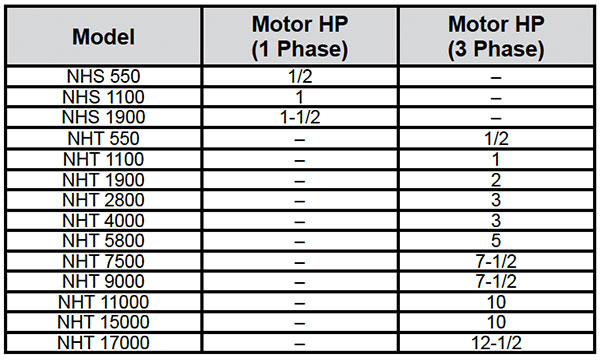

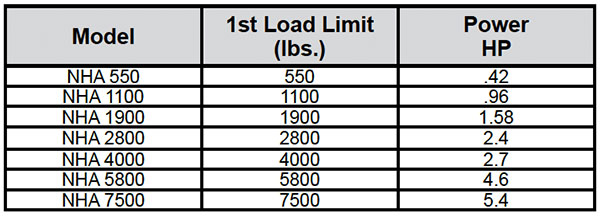

Heavy-Duty Hauling Winches

Winch Drums—Drums are steel fabricated and designed to specific loading capacity. Drums are sized according to ASME B30.7.2006 to provide a minimum pitch diameter of 15 times the nominal rope diameter.

Direct Drive—A simple, direct-drive design increases the efficiency of the winch and eliminates drive chains or bull gears to maximize power output.

Any Position—An open-base design permits mounting in horizontal or vertical positions. Loads can be pulled through the base itself, which is particularly useful in limited-space installations.

All Ball & Roller Bearings—Friction load loss is reduced to a minimum through the use of ball and roller bearings. No bushings means higher efficiency and more power for pulling.

Power In – Power Out—For added safety, all winches are fully reversible. This gives the operator complete control of the winch load in both directions at all times.

Gear Reducers—All Jeamar hauling winches have high-efficiency helical gear reducers plus high-capacity, anti-friction bearings for long life, low noise and high output torque.

Breaking Systems—The full range of Jeamar’s heavy-duty hauling winches are available with 3-phase motors in any standard voltage at 50 or 60 Hz.

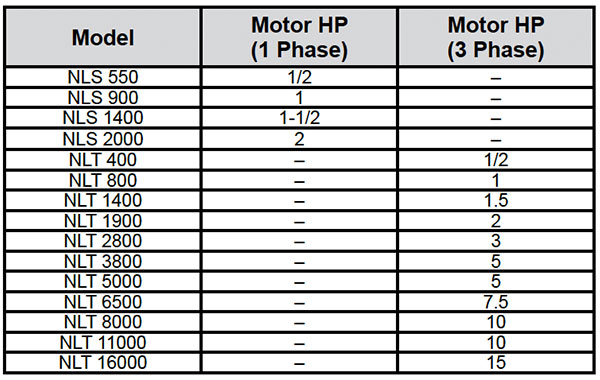

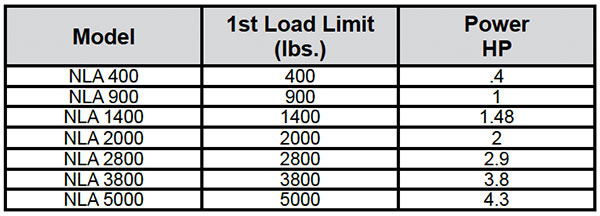

Heavy-Duty Lifting Winches

Winch Drums—Drums are steel fabricated and designed to specific loading capacity. Drums are sized according to ASME B30.7.2006 to provide a minimum pitch diameter of 18 times the nominal rope diameter.

Direct Drive—A simple, direct-drive design increases the efficiency of the winch and eliminates drive chains or bull gears to maximize power output.

Any Position—An open-base design permits mounting in horizontal or vertical positions. Loads can be pulled through the base itself, which is particularly useful in limited-space installations.

All Ball & Roller Bearings—Friction load loss is reduced to a minimum through the use of ball and roller bearings. No bushings means higher efficiency and more power for pulling.

Power In – Power Out—For added safety, all winches are fully reversible. This gives the operator complete control of the winch load in both directions at all times.

Electric Motors—The full range of Jeamar’s heavy duty lifting winches are available with 3-phase motors in any standard voltage at 50 or 60 Hz. Single-phase units are available on loads up to 2000 lbs.

Gear Reducers—All Jeamar lifting winches utilize high-efficiency helical worm or worm gear reducers plus high-capacity, anti-friction bearings for long life, low noise and high output torque.

Breaking Systems—Standard on all heavy-duty lifting winches, the electromagnetic brake is a disc-type that is activated automatically in the event of a power interruption. The brake will stop the winch and hold the load securely.

Heavy-Duty Air Hauling

Winch Drums—Drums are steel fabricated and designed to specific loading capacity. Drums are sized according to ASME B30.7.2006 to provide a minimum pitch diameter of 15 times the nominal rope diameter.

Direct Drive—A simple, direct-drive design increases the efficiency of the winch and eliminates drive chains or bull gears to maximize power output.

Any Position—An open-base design permits mounting in horizontal or vertical positions. Loads can be pulled through the base itself, which is particularly useful in limited-space installations.

Ball & Roller Bearings Throughout—Friction load loss is reduced to a minimum through the use of ball and roller bearings. No bushings means higher efficiency and more power for pulling.

Power In – Power Out—For added safety, all winches are fully reversible. This gives the operator complete control of the winch load in both directions at all times.

Gear Reducers—All Jeamar air winches have high-efficiency helical reducers plus high-capacity, anti-friction bearings for long life, low noise and high-output torque. Totally enclosed reducers make them weatherproof.

Air Motors—Jeamar air motors are fully reversible vane-type. Positive starting and precise control are central features of the motors, which have been designed for long life and low-cost operation. They can be stalled indefinitely under load without harm to the motor. Note that when moving loads on an incline, it is essential that a brake be used.

Control Valves—Control valves feature proportional flow with spring return to neutral for “deadman” operation. Valves control the winch speed by varying air flow to the motor. With the control released, air flow is cut off, stopping the winch. Controls are supplied loose to allow for mounting that is appropriate to the application.

Heavy-Duty Air Lifting

Winch Drums—Drums are steel fabricated and designed to specific loading capacity. Drums are sized according to ASME B30.7.94 to provide a minimum pitch diameter of 15 times the nominal rope diameter.

Direct Drive—A simple, direct-drive design increases the efficiency of the winch and eliminates drive chains or bull gears to maximize power output.

Any Position—An open-base design permits mounting in horizontal or vertical positions. Loads can be pulled through the base itself, which is particularly useful in limited-space installations.

Ball & Roller Bearings Throughout—Friction load loss is reduced to a minimum through the use of ball and roller bearings. No bushings means higher efficiency and more power for pulling.

Power In – Power Out—For added safety, all winches are fully reversible. This gives the operator complete control of the winch load in both directions at all times.

High Service Factors—Jeamar winches are designed and manufactured for continuous, heavy-duty operation with a minimum service factor of 1 (one).

Gear Reducers—All Jeamar air winches have high-efficiency helical reducers plus high-capacity, anti-friction bearings for long life, low noise and high-output torque. Totally enclosed reducers make them weatherproof.

Air Motors—Jeamar air motors are fully reversible vane-type. Positive starting and precise control are central features of the motors, which have been designed for long life and low-cost operation. They can be stalled indefinitely under load without harm to the motor.

Control Valves—Control valves feature proportional flow with spring return to neutral for “deadman” operation. Valves control the winch speed by varying air flow to the motor. With the control released, air flow is cut off, stopping the winch. Controls are supplied loose to allow for mounting that is appropriate to the application.

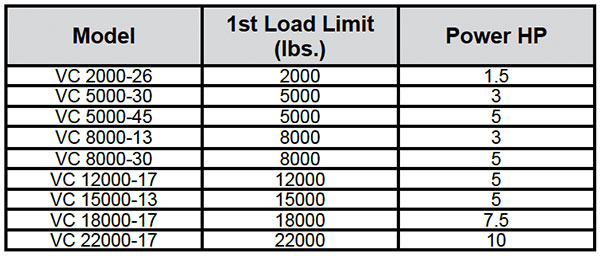

Capstan Winches

Direct Drive—A direct-drive design increases the efficiency of the winch and eliminates drive chains or bull gears to maximize power output.

Any Angle—The rope can leave the drum at any angle, enabling the operator to stand in the most appropriate, out-of-line-of-sight location. For safety, the load line shall be the bottom wrap on the capstan head and the lead line going to the operator will be the top wrap of the drum.

Gear Reducers—All Jeamar capstan winches utilize high-efficiency worm, helical, helical-worm or helical-bevel reducers, plus high-capacity, anti-friction bearings designed for long life, low noise and higher output torque.

High Starting Loads—High-starting-torque, 3-phase motors are available in all standard voltages at 50 & 60 Hz. These motors are suited to railcar pulling where momentary overloads occur when a railcar is started in motion. Single-phase motors at 115-230 volts at 50 and 60 Hz are available as an option on some models.

Options—Foot switches, Air powered, Hydraulic powered and Explosion Proof are just some the options available.