Description

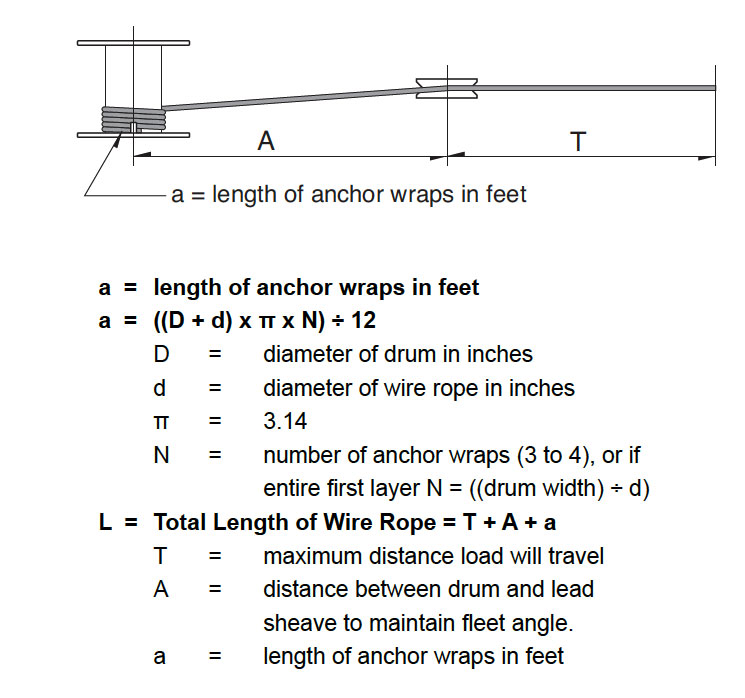

Anchor Wraps

The first 3 to 4 wraps of wire rope must remain on the drum at all times to act as anchor wraps and help secure the wire rope to the drum. The length of wire rope used for anchor wraps must be added to the total travel distance to determine the length of the wire rope needed for the application.

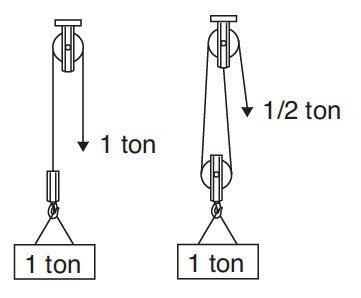

Two Part Line

In some applications, a two-part line can be used to effectively increase the size of load the winch can move. A two-part line reduces tension in the wire rope, it does not change the weight of the load. All equipment supporting the load, such as sheave blocks, must be rated for the full size of the load.

As the number of rigging lines increase, line pull and line speed decrease. Friction in the system also affects performance. As the number of rigging lines increase, friction also increases. Contact your local Lifting Specialist for more information.

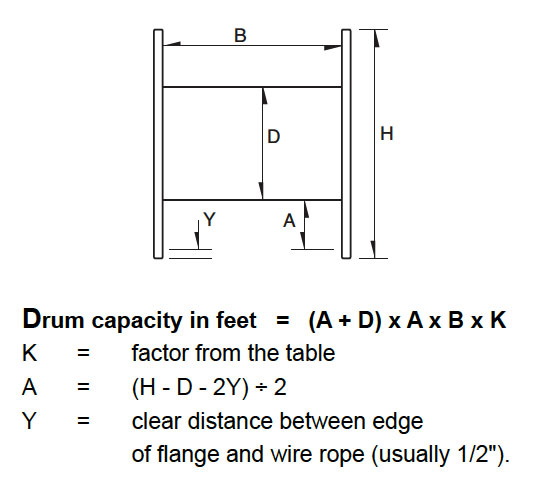

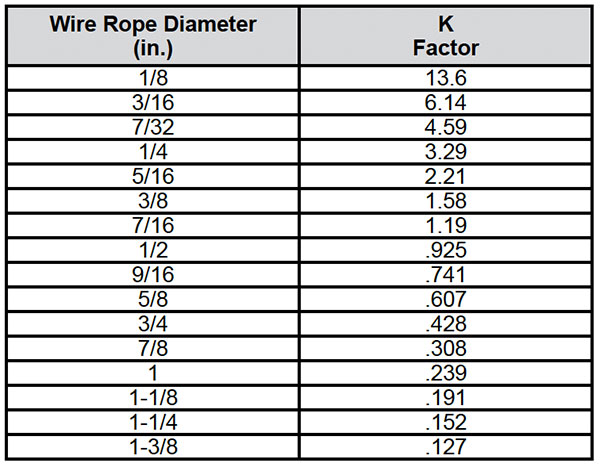

Drum Capacity

Full drum capacity is typically calculated using the formula shown below. This formula is based on the practices of wire rope manufacturers and assumes uniform winding of the wire rope. In actual practice, drum capacities may be 25-30% less than the values given by this formula due to uneven spacing, loose winding and overlapping. Drum capacity often determines the winch you select. Most power winches can be equipped with different sizes of wire rope. Larger diameter wire ropes will decrease drum capacity, smaller diameter wire ropes will increase drum capacity.

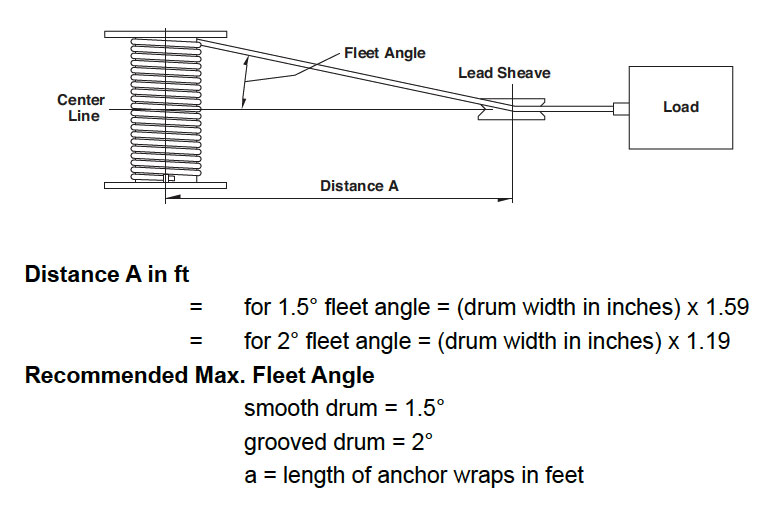

Fleet Angle

Fleet angle is the angle between the wire rope and an imaginary line extending perpendicular to the drum. The fleet angle varies with the distance between the lead sheave and the drum. The proper fleet angle helps the wire rope to wind evenly onto the drum, and helps to reduce wear to the wire rope, drum and lead sheave. Too large a fleet angle will cause the wire rope to wind loosely, overlap and possibly jump the flange and cause severe damage to the equipment. A maximum fleet angle of 1-1/2° for smooth drums, and 2° for grooved drums, helps the wire rope wind uniformly.

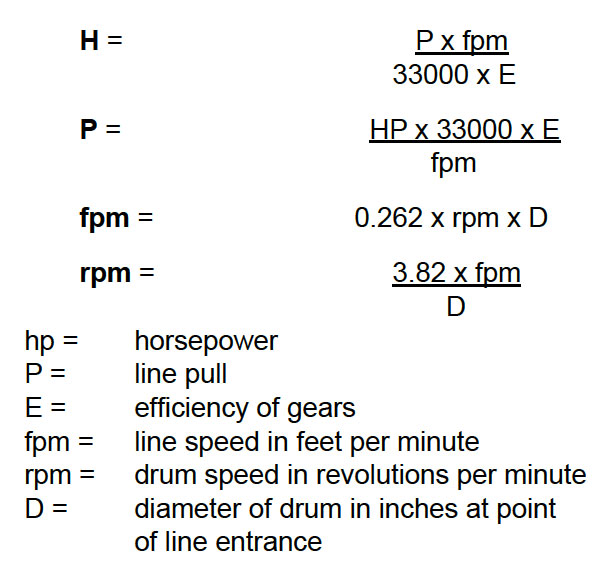

Formulas