What Is a Snatch Block? How It Works and When to Use One

This article explains what a snatch block is, how it works, when to use one, and how you can get the most out of this versatile rigging tool.

Estimated reading time: 8 minutes

Snatch blocks aren’t as visible as a crane hook or wire rope, but when you need to redirect a line, increase pulling power, or solve an unusual problem, it can be the piece of equipment that makes the job possible and safer for everyone involved.

However, operators may not know when to use one, what makes them different from a standard pulley, or how to select the right block for the job. Misapplication can lead to damaged rope, reduced efficiency, and even unsafe lifting conditions.

This article explains what a snatch block is, how it works, when to use one, and how you can get the most out of this versatile rigging tool.

Table of contents

- What Is a Snatch Block?

- Types of Snatch Blocks and Configurations

- How Does a Snatch Block Work?

- Example: Mechanical Advantage in Action

- When Should You Use a Snatch Block?

- Wire Rope vs. Synthetic Rope in Snatch Blocks

- What are the Benefits of Using a Snatch Block?

- Mistakes to Avoid When Using Snatch Blocks

- Final Thoughts: Why Snatch Blocks Are a Flexible Rigging Tool

- FAQs About Snatch Blocks

What Is a Snatch Block?

A snatch block is a type of pulley block where one of its side plates swings open. This allows a rope or line to be inserted midspan, rather than feeding it through from the end. That one difference makes it far quicker and more adaptable than a standard block.

- The swing-open side plate “snatches” shut around the rope, giving the block its name.

- Quality snatch blocks are rated for both lifting and pulling, unlike some general-purpose pulleys.

- They are compatible with wire rope and synthetic rope, provided the rope size matches the sheave groove and the correct D/d ratio is maintained.

Because of this design, snatch blocks are valued for temporary and flexible applications where speed and adaptability are critical.

Types of Snatch Blocks and Configurations

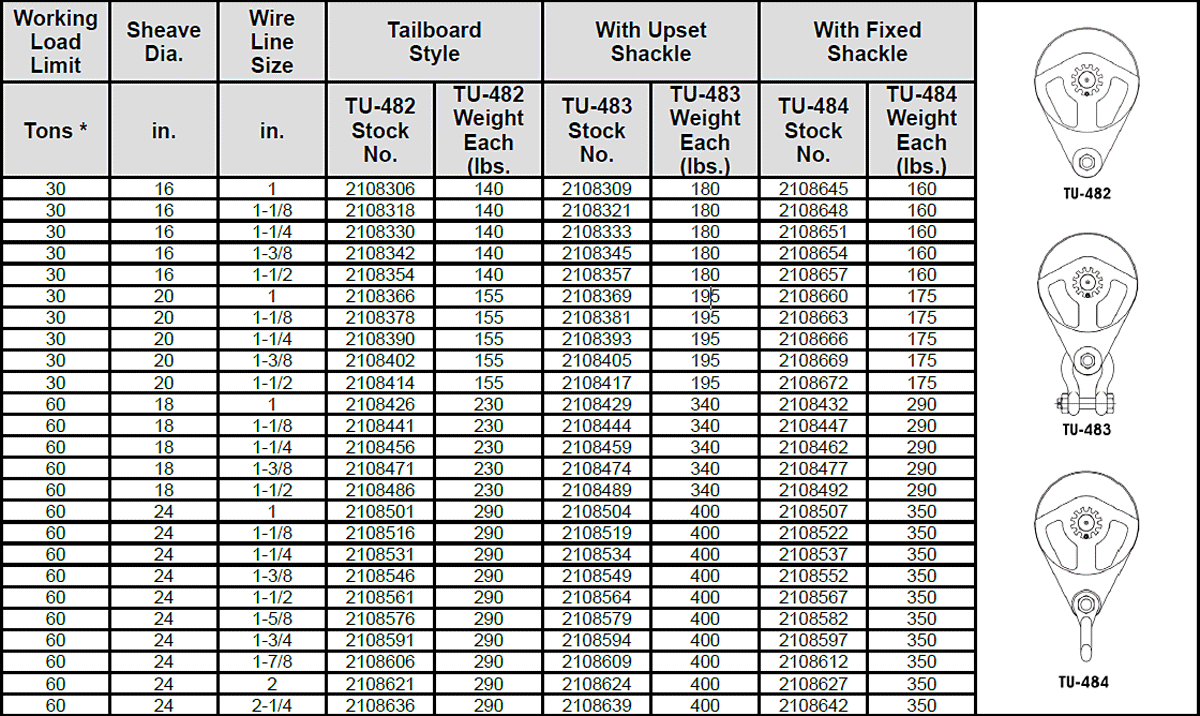

Not all snatch blocks are the same. Manufacturers offer different models tailored to specific applications.

- Shackle snatch blocks: Designed with a shackle fitting for easy connection to anchors, slings, or towing points.

- Hook snatch blocks: Equipped with a hook for quick attachment to lifting points.

- Tailboard snatch blocks: Designed to be permanently or semi-permanently fixed to a structure with a pin connection.

Choosing the right type often depends on how you intend to attach the block and whether the application is temporary or fixed. For example, towing operators often favor hook or shackle snatch blocks for quick deployment, while oil field crews may choose tailboard options for more stable, anchored setups.

How Does a Snatch Block Work?

At its core, a snatch block functions like a pulley: it allows a rope to move around a sheave to change direction or multiply pulling power. Snatch blocks guide rope around obstacles or into new directions. For example, pulling a vehicle out of a ditch at an angle.

By reeving rope through one or more snatch blocks, the load is distributed over multiple parts of line. This increases pulling capacity, though it also reduces lifting speed.

The ability to insert rope without unreeving saves time and simplifies setup, especially when the rope already has terminations attached.

Example: Mechanical Advantage in Action

Suppose you’re using a winch rated for 2,000 lbs. of line pull. By adding a single snatch block to the load, you now have two parts of line sharing the force. The system can now move roughly 4,000 lbs., though it will move at half the speed. Add a second block to the load, and the load carrying capability increases again, allowing the system to handle even heavier loads with the exact same winch you started with.

This is why snatch blocks are sometimes referred to as “force multipliers” in rigging. They allow relatively small winches or cranes to handle much heavier loads safely when configured correctly.

When Should You Use a Snatch Block?

Snatch blocks are widely used across industries that need flexible, temporary lifting or pulling solutions. Some of the most common applications include:

- Towing & Recovery: Tow trucks and rotator rigs may carry a dozen or more snatch blocks for complex recoveries.

- Construction: Used to redirect loads around obstacles, lift at different angles, or adjust load path on site.

- Logging & Forestry: Helps move felled timber across uneven terrain without direct line-of-sight pulls.

- Mining: Essential for pulling equipment or ore through tunnels, shafts, or angled spaces.

- Oil & Gas: Used both onshore and offshore to redirect heavy pipe or rigging lines safely.

- Maritime: Ports and shipyards rely on them for mooring adjustments, pulling lines, or vessel maintenance.

In all these industries, the snatch block is chosen because it provides adaptability in the field.

Wire Rope vs. Synthetic Rope in Snatch Blocks

Traditionally, snatch blocks have been paired with wire rope. However, as synthetic ropes become more common, questions about compatibility are increasing.

Wire rope provides strength and durability but is heavy and less flexible. For long lengths of rope, weight alone can be difficult to manage. Synthetic rope offers lightweight handling and greater flexibility. It is often preferred in situations where rope weight makes wire rope impractical, or where manual handling is frequent.

Most snatch blocks designed for wire rope can also work with synthetic rope, but it is critical to verify the sheave groove profile with the rope manufacturer and adjust the sizing—often moving up to the next larger wire rope groove size to prevent pinching.

The choice between wire and synthetic often comes down to the balance between durability and handling.

What are the Benefits of Using a Snatch Block?

Snatch blocks provide several key advantages:

Versatility

Suitable for lifting, pulling, or redirecting in countless configurations.

Time savings

Swing-open plates make midline installation faster.

Increased capacity

Reeving adds parts of line, multiplying available pulling power.

Equipment protection

Distributes load across more line segments, reducing strain on winches and extending rope life.

The greatest benefit, however, is flexibility.

Mistakes to Avoid When Using Snatch Blocks

Even though snatch blocks are versatile, they must be used correctly. Common mistakes include:

Overloading

Exceeding the working load limit or failing to calculate line forces correctly can cause failure (OSHA 1910.184)

Mismatched rope size

Using rope too large or too small for the sheave groove accelerates wear.

Skipping inspection

Failing to check for sheave wear, using bent components, or not addressing latch functionality undermines safety. Always conduct a pre-use inspection before using a snatch block.

Understanding these pitfalls helps operators avoid costly downtime and safety incidents.

Final Thoughts: Why Snatch Blocks Are a Flexible Rigging Tool

Snatch blocks are a versatile, problem-solving rigging tool. Their ability to redirect rope, multiply pulling force, and attach midline make them indispensable in industries like towing, construction, oil and gas, forestry, and maritime.

The key to safe use lies in proper selection and application. Matching rope size, sheave diameter, and working load limit ensures that the block extends rope life, protects equipment, and safeguards the crew.

If you’re planning a lift or pull and aren’t sure which snatch block is right, don’t guess. At Mazzella, we partner with Kito Crosby, one of the most respected snatch block manufacturers in the industry. Contact Mazzella’s lifting and rigging experts to review your application and get guidance on the safest and most efficient option.

FAQs About Snatch Blocks

Copyright 2025. Mazzella Companies.