What Are the Different Grades of Chain?

What exactly does the number in the grade of a chain or chain sling stand for? Understanding the different grades of chain will help you understand how to use chain products correctly and safely in lifting and tie-down applications.

You may have heard the terms “Grade 80 Alloy chain,” or “carbon chain” thrown around without actually understanding what they mean. What exactly does that number in the title of a chain or chain sling stand for? What does it indicate about the chain? Understanding what uses each grade of chain is recommended for is imperative to using chain products accurately and safely.

For the purpose of discussing chain used in the rigging industry, the information in this article will be limited only to graded welded chain—weldless chain is not permitted for use in rigging applications. The number in the title of the welded chain—Grade 80 Alloy, Grade 43, Grade 70 “Transport Chain,” etc.—refers to the grade of chain. The higher the grade is, the stronger and more resistant to bending and breaking the chain is.

If you are newer to rigging, haven’t been properly educated on chain grades, or could just use a review on what they are, continue reading this article and you might benefit from the following information:

- The differences between grades of chain

- What the different grades of chain are

- The difference between carbon and alloy chain

- How chain grade and price are related

- Common problems related to chain use and chain grade

What is the Difference Between Grades of Chain?

Welded chain comes in various different strengths, referred to as “grades” on the market. The grade, indicated by a number, represents the strength—or mean stress value—of the chain. As the chain grade number increases:

- The material of the chain is typically harder and more resistant to abrasion

- Strength-to-weight ratio increases

- Working Load Limit (WLL) increases

The number that indicates the grade of the chain is a representation of the solution to a mathematical equation. This equation takes the tensile force of the chain —measured in Newtons—and divides it into the cross-sectional area of the link size on that chain in millimeters.

The simplified equation is as below:

Newtons / millimeters2

From this equation, you get the number that corresponds to the grade of the chain. The higher the grade number, the higher the tensile force is in comparison to the size of the chain links—resulting in a higher strength-to-weight ratio.

The biggest difference between grades of chain is that carbon steel chain—Grade 30, 43, and 70—is not recommended for overhead lifting, while alloy steel chain—Grade 80, 100, and 120—is recommended for use in sling assemblies and overhead lifting applications.

What Are the Different Grades of Chain?

For rigging purposes, there are six main grades of welded chain that are sold on the market, broken into two main categories:

- Carbon steel chain

- Alloy steel chain

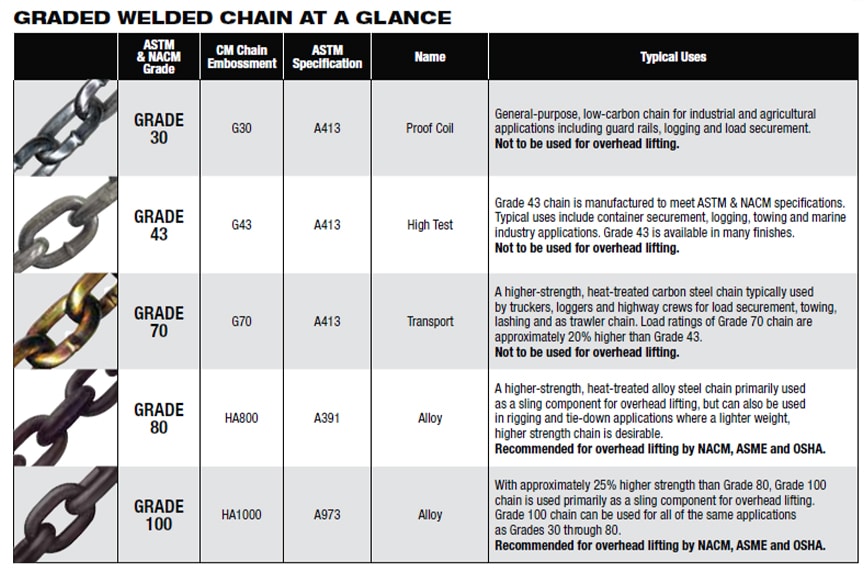

The CM chart featured in this section provides a general overview of graded welded chain and the differences between each of them. Below, we will dive into each grade of welded chain.

Carbon Chain

Carbon chain is most commonly used for tie down and container securement purposes and is not recommended for overhead lifting by Occupational Safety and Health Administration (OSHA) or American Society of Mechanical Engineers (ASME).

Other regulations for carbon chain can be found in the American Society for Testing and Materials (ASTM) A413 – Standard Specification for Carbon Steel Chain.

Another organization to keep in mind when it comes to load securement and cargo is the Department of Transportation (DOT) and, by extension, the Federal Motor Carrier Safety Administration (FMCSA). The DOT allows for use of any graded chain for cargo securement as long as it meets the FMCSA cargo securement regulations.

The only instance in which carbon chain should ever be considered for use in overhead lifting is in a caustic—harsh acidic—environment. Caustic environments that require the use of chain include pickling applications and galvanizing operations.

Much of the work in these harsh caustic environments involves using chain slings to wrap around, lift, and lower a load into an acidic chemical bath—this process is called bundling. When chain slings are used in bundling, a lower grade of steel is preferred because it is less likely to be attacked and damaged by acids.

In many cases, shops with a caustic environment will not permit the use of alloy chain slings as they will be more easily damaged and destroyed by the harsh chemicals present.

Grade 30 Carbon Chain

This is the lowest chain grade available on the market when it comes to graded welded chain, and is commonly referred to as “proof coil.” Grade 30 is a rather generic type of chain that can be used anywhere from logging, trucking tie downs, or even on playground equipment.

As mentioned above, carbon chain, in general, is commonly used in bundling applications where alloy chain is typically not permitted. In fact, the lower the carbon content in the chain for bundling applications, the better. So, it is not uncommon to see Grade 30 chain as part of sling assemblies used for bundling.

Grade 43 Carbon Chain

While Grade 43 chain has a slightly higher strength-to-weight ratio in comparison to Grade 30, the two chain grades are often used interchangeably. Grade 43 Chain is commonly referred to as “High-Test Chain,” and is most often used for:

- General utility

- Towing

- Load securement

Grade 70 Carbon Chain

Grade 70 chain is the highest grade you can purchase within the carbon chain category. Like Grade 30 and 43 chain, it is not recommended for overhead lifting. Unlike Grade 30 and 43 chain, it is heat-treated, making it more resistant to wear and abrasion as it is a harder material with a higher strength-to-weight ratio.

Also known as “Transport Chain,” Grade 70 chain is most commonly used for tie down and load securement applications for trucking and other cargo. While Grade 30 and 43 chain can also be used for load securement, Grade 70 chain provides a stronger, more durable option with a much higher strength-to-weight ratio.

Grade 70 chain is most commonly manufactured with a gold-colored finish and is recognized throughout the industry as such. When trained properly, this can be an easy identifier for riggers to make sure they avoid using it for lifting applications.

Alloy Steel Chain

Unlike carbon chain, all graded alloy steel chain is recommended for overhead lifting applications by OSHA and ASME. Meaning, alloy chain may also be used to construct chain sling assemblies for overhead lifting in addition to the various securement applications that carbon chain is capable of.

Alloy chain is recommended for overhead lifting because its higher strength-to-weight ratio provides a product that is capable of a much higher elongation percentage—20% minimum—before breaking when overloaded. Basically, higher chain grades correlate with stronger material and a higher resistance to bending or breaking in the event of impact or overloading.

Grade 80 Alloy Steel Chain

Grade 80 chain is recommended by OSHA for overhead lifting applications and is most commonly used in sling assemblies. Other regulations can be found in ASTM A391 – Standard Specification for Grade 80 Alloy Steel Chain.

In the majority of cases, either Grade 80 or Grade 100 chain can be used for a lifting application. However, there are some situations in which Grade 80 is the better choice.

Grade 100 chain is tempered at a lower temperature than Grade 80 chain. This becomes important in steel mills, where chain that has been tempered at the highest possible temperature is preferable, as it is less likely to be permanently degraded by the extreme temperatures present in the mill. So, in steel mills—or other high-heat environments—Grade 80 chain is a preferred, often mandated, option.

The components of a Grade 100 chain sling become extremely large in comparison to Grade 80 components once you move up in link diameter, and tend to offset the strength-to-weight ratio advantage of having a Grade 100 sling. In fact, most manufacturers sell up to a larger link diameter in Grade 80 chain than they do for Grade 100 chain—CM, for example, sells up to 1-¼” diameter on Grade 80 chain slings, but only up to ¾” diameter in Grade 100 chain slings. So, if your application requires an extremely high-capacity chain sling, you will likely need to use Grade 80 chain for the job—or explore sling options made from other materials.

Grade 100 Alloy Steel Chain

Like Grade 80 chain, Grade 100 chain is recommended by OSHA and ASME for overhead lifting applications and is most commonly used in sling assemblies. Other regulations can be found in ASTM A973 – Standard Specification for Grade 100 Alloy Steel Chain.

In comparison to Grade 80, Grade 100 chain has a significantly higher strength-to-weight ratio—about 25% higher, depending on the manufacturer. Grade 100 chain also has a slightly harder surface material, which gives it some advantage when it comes to abrasion resistance.

In most cases, either Grade 100 or Grade 80 chain can be used for the application. The only situation in which Grade 100 chain may be necessary is if the application is heavily concerned with the strength-to-weight ratio of the lifting sling, as Grade 100 chain slings have the advantage there.

In cases where you may have a heavy-duty chain sling—above ¾” in link diameter—Grade 100 chain slings become heavy, unruly, and require larger end fittings in comparison to a similar Grade 80 chain sling would. In the case that your application requires a chain sling with a rather large diameter—and strength-to-weight ratio isn’t a main concern—Grade 80 is probably the better choice.

Grade 120 Alloy Steel Chain

This type of high-performance alloy chain is characterized by its square links—as opposed to the rounded links used to construct all other chain grade options. Grade 120 chain is often indicated by a blue, green, or other bright-colored finish.

As a general rule—depending on the manufacturer—Grade 120 chain has a higher strength-to-weight ratio than Grade 100 chain. This is because the square links used to construct Grade 120 chain create a larger cross-sectional area per chain link.

Square link chain is more costly to manufacture, and therefore creates a more expensive end product. Grade 120 chain is not utilized nearly as frequently as Grade 100 or Grade 80 chain in overhead lifting. Only on rare occasions will it be completely necessary to utilize a Grade 120 chain—in most cases the less expensive option of Grade 100 or Grade 80 chain could be applied instead.

How Does Chain Grade Affect Price?

As a general rule, as the grade of chain increases, the more expensive the material and production process is—resulting in a higher price for the end product.

The most significant price jumps in the grades of chain occur:

- Between Grade 43 and Grade 70 carbon chain

- Between Grade 70 carbon chain and Grade 80 alloy chain

The significant price difference between Grade 43 and Grade 70 chain is because Grade 70 chain is heat-treated while Grade 43 and 30 are not. Heat-treating is an added expense in the manufacturing process that creates a stronger, more durable product.

The significant price difference between Grade 70 carbon and Grade 80 alloy chain is because the chain material is being upgraded from carbon to alloy steel. Once you make the jump from carbon chain to alloy chain, the price changes significantly. This is because the raw material used to make alloy chain is much more expensive and results in a product with a significantly higher strength-to-weight ratio and overall stronger material that is recommended for overhead lifting.

Increase in chain grades comes along with alloy material and more capabilities, which makes it understandable that the price would increase accordingly. However, this is not always the case.

For example, Grade 30 and 43 chain are often priced at the same point—the same goes for Grade 80 and Grade 100 chain.

While Grade 100 chain has a slightly higher strength-to-weight ratio than Grade 80, the advantages are not particularly significant. The same goes for the difference between Grade 30 and Grade 43 chain.

Grade 80 and Grade 100 chain is, more often than not, sold interchangeably. Likewise, Grade 30 and 43 chain is commonly used and sold interchangeably.

Common Problems Related to Chain Grade

It is much more common for mistakes involving chain and use of correct chain grade to be made by uninformed, or untrained, riggers. This is why it is extremely important for the safety of your personnel and equipment to ensure that your riggers are trained properly and to OSHA and ASME standards.

We asked experts at CM to share with us some common problems that they encounter in the field when it comes to chain and using the correct grade for the application. The three most common problems they encounter when it comes to chain and chain grade are:

- Using hoist load chain for lifting applications

- General misuse and abuse of alloy chain

- Use of Grade 70 chain for overhead lifting

#1 Using Hoist Load Chain for Lifting Applications

Load chain—the chain used inside a hoist—is constructed very differently from the alloy chain used in slings for overhead lifting. One common problem the experts at CM come across is riggers in a facility using the hoist chain to wrap around / connect directly to loads for overhead lifting. There are several reasons that this is not compliant:

- Load chain is designed specifically for use within the inner workings of a hoist. It is NOT graded for directly connecting to and lifting a load as a sling would.

- Load chain does not meet the same elongation or hardness requirements as a Grade 80 or Grade 100 chain does.

- If the lift causes any deformation in the load chain, when it is retracted back into the hoist, it could cause damage to and destroy the hoist.

Load chain is designed specifically for the hoist that it is installed in. It is not graded for the stress and rigor of overhead lifting that alloy chain slings are recommended for.

#2 General Misuse and Abuse of Alloy Chain

The second most common problem the experts at CM encounter when it comes to chain, is general misuse and abuse of chain slings. General misuse and abuse of alloy chain slings refers to, but is not limited to:

- Improper storage of equipment, such as leaving slings laying around the shop floor.

- Failing to get frequent enough inspection of your slings (based upon the severity of the application).

- Frequent overloading or improper usage of slings.

Ensuring proper maintenance and storage of your lifting slings is extremely important for both safety of personnel and preserving the life of your equipment. When you don’t properly protect and maintain your lifting slings, you increase the chances of a dropped load, damaged property, injury, or worse.

#3 Grade 70 Chain Used for Overhead Lifting

Another common mistake CM experts see in the field is the use of Grade 70 chain assemblies used in place of a comparable Grade 80 or Grade 100 single-leg chain sling.

As we talked about above, Grade 70 chain is not recommended for use in overhead lifting applications. The WLL, strength-to-weight ratio, and elongation factors simply do not meet the same expectations required by Grade 80 and Grade 100 chain.

Wrapping It Up

We hope that this article helped you to form a base level understanding of what chain grade means, what the different chain grades are, and how they differ from one another.

Basically, the grade of a chain refers to the strength of the chain and can indicate the type of material it is manufactured from. The higher the number, the stronger and harder the chain is, the higher the WLL, and the higher the strength-to-weight ratio.

To sum it up, there are two main categories of welded chain: carbon and alloy steel chain.

Carbon steel chain is:

- A lower grade than alloy chain—30, 43, 70

- Not recommended by OSHA or ASME for overhead lifting

- Most often used in load securement, tie downs, and bundling applications

Alloy steel chain is:

- A higher grade than carbon chain—80, 100, 120

- Recommended by OSHA and ASME for overhead lifting

- Not recommended for bundling applications

The grade of chain does affect price, but not as much as you might think. The price of chain has the most significant increase when it jumps from not heat-treated—Grade 30 and 43—to heat-treated Grade 70 carbon chain, and from carbon chain to alloy chain.

Some common problems when it comes to grade of chain are:

- Using hoist load chain for lifting applications

- General misuse and abuse of alloy chain

- Using Grade 70 chain for overhead lifting

How We Can Help

At Mazzella, we are a proud partner, distributor, and authorized repair center of CM and Peerless / Acco chain products including, but not limited to:

- Grade 80 Alloy chain and sling assemblies

- Grade 100 Alloy chain and sling assemblies

- Carbon chain

We also carry a full line of other rigging products including rigging hardware from CM, Crosby, and Gunnebo Industries. Download our Lifting Slings Types and Terms E-book to learn more about alloy chains and other popular lifting sling options.

If you are interested in learning more or speaking with a Lifting Specialist about your chain options, contact us today!

Chain Products

Are you looking for your lifting or load securement applications? You can count on us to stock an assortment chain products for all types of applications, including a complete line of both alloy and carbon chains, as well as fittings.

Call us at 800.362.4601 or click here if you need alloy or carbon chain products!

Copyright 2020. Mazzella Companies.