The American Society of Mechanical Engineers (ASME) is a professional association and leading international developer of codes and standards associated with the art, science, and practice of mechanical engineering. ASME membership is comprised of engineers, scientists, government officials, and others who voluntarily contribute their technical expertise.

Every couple of years, the B30 Committee reviews, revises, and amends their existing standards and releases a new edition, based on:

- Technological advances

- New Data

- Changing environmental and industry needs

In this article, we’ll discuss the revisions, updates, and additions to the newly released ASME B30.2 Overhead and Gantry Cranes standard, compared to the previously released 2016 edition.

What is ASME B30.2-2022 Overhead and Gantry Cranes?

The first ASME B30.2 Overhead and Gantry Cranes standard was issued in 1996, Since then, this standard has been revised and published by the B30 Committee in 2001, 2005, 2011, and 2016.

The new ASME B30.2 Overhead and Gantry Cranes standard revises and supersedes the procedures outlined in the 2016 edition of the same standard.

According to the standard itself, ASME B30.2-2022 Overhead and Gantry Cranes includes provisions that apply to the construction, installation, operation, inspection, and maintenance of hand-operated and power-driven overhead and gantry cranes that have a top-running single girder or multiple girder bridge, with one or more top-running trolley hoists used for vertical lifting and lowering of freely suspended, unguided loads consisting of equipment and materials.

The requirements included in this Volume also apply to cranes having the same fundamental characteristics such as cantilever gantry cranes, semi-gantry cranes, and wall cranes.

What’s New in ASME B30.2 Overhead & Gantry Cranes?

One of the more notable changes early in the ASME B30.2 Overhead and Gantry Cranes standard is the revision of definitions for lifting device and load block.

The new edition of ASME B30.2 Overhead and Gantry Cranes standard defines a lifting device as: “a device, other than a load block, used for attaching a load to a hoist. The device may contain components such as slings, hooks, and rigging hardware addressed by other ASME B30 volumes or standards. The weight of these devices is to be considered part of the rated load if it is not reeved onto the hoist ropes.”

Previously, the definition was: “devices that are not reeved onto the hoist ropes, such as hook-on buckets, magnets, grabs, and other supplemental devices used for ease of handling certain types of loads. The weight of these devices is to be considered part of the rated load.”

ASME B30.2-2022 Overhead and Gantry Cranes defines a load block as: “the assembly of hook or shackle, swivel, bearing, sheaves, pins, and frame suspended by the hoisting rope or load chain.”

Previously, the definition was: “the assembly of hook or shackle, swivel, bearing, sheaves, pins, and frame suspended by the hoisting rope or load chain. This shall include any appurtenances reeved in the hoisting ropes.”

What Other Changes Have Been Made in ASME B30.2-2022 Overhead & Gantry Cranes?

Chapter 1: General Construction and Installation

Section 2-1.3.1-Foundations and Anchorages

For this section, Subparagraph (g) was revised to read: “A wind speed indicating device shall be provided for cranes used outdoors. The device shall be mounted on the crane or the crane runway structure and shall give a visible and audible alarm to the crane operator at a predetermined wind speed. A single wind speed indicating device may serve as an alarm for more than one crane.”

Section 2-1.3.2-Crane Runways

In this section, multiple paragraphs were revised to say the steel crane runways and supporting structures should conform to the design parameters as specified in ANSI / AISC 360-16. Previously, the reference was listed as “in the applicable AISC Manual of Steel Construction.

Additionally, the Runway Stops subsection was revised to read:

- Stops shall be provided at the limits of travel of the bridge or gantry structure

- Stops shall engage the bumpers or bumper pads mounted on the bridge or gantry structure

- Stops shall be designed to withstand the forces applied by the bumpers

“Gantry structure” was added to the first two subparagraphs and “by the bumpers” replaced “to the bumpers.”

Section 2-1.8.1-Trolley Stops

The words “bumper pads” were removed, and now, the standard reads, “Stops shall engage the bumpers mounted on the trolley.”

Section 2-1.8.2-Bridge and Gantry Bumpers

The former title of the subsection was “Bridge Bumpers.”

Section 2-1.8.3 Trolley Bumpers

Subparagraph (3) now reads: “be designed and installed with a means of retaining the bumper in case of broken or loosened mounting connections. The retention requirement for elastomeric bumpers may be omitted if determined unnecessary by a qualified person.”

Previously, it read: “be designed and installed with a means of retaining the bumper in case of broken or loosened mounting connections.”

Other subparagraphs were revised, deleted, and / or redesignated in Sections 2-1.9.1, 2-1.9.2, 2-1.13.3 and 2-1.13.5.

Section 2-1.9.3 Gantry Rail Sweeps

This subsection was not in the 2016 edition.

Now, it states:

- Gantry truck rail sweeps shall be provided in front of the leading wheels on both ends of the gantry end truck

- Rail sweeps should extend below the top of the rail

- The rail sweep shall clear the rail of objects on the runway which, if they came into contact between the wheel and rail, could cause damage to the wheel or derail the wheel

Section 2-1.13.5 Disconnecting Means

Subparagraphs (b) and (c) were revised. Subparagraph (d) was added, and states: “When operation of the push button or switch controlling the main line contactor in (c) will result in uncontrolled movement of the load (such as when a hoist that is equipped with a brake failure detection circuit detects a brake failure), the control circuit may temporarily maintain power to the crane to prevent uncontrolled movement of the load.”

Section 2-1.13.8 Crane Powered Lifting Devices

Previously, this section was titled: “Cranes With Lifting Magnets,” and it was revised in its entirety.

Now, the standard reads:

- When a loss of power to a lifting device would cause uncontrolled movement of the load, a separate lifting device disconnect switch shall be connected on the line side (power supply side) of the crane disconnect switch. The lifting device disconnect switch shall be of the enclosed type with provision for locking in the open (off) position.

- For lifting magnets, a means shall be provided for discharging the inductive load.

- Indication or signal lights should be provided to indicate that power to a powered lifting device is on. These lights, if used, shall be visible to the crane operator and to persons on the floor.

- For a remote-operated crane, the loss of the remote signal shall not result in loss of power to the lifting device.

- A minimum of two collectors for each runway conductor shall be furnished when the crane is used with a powered lifting device.

- Lifting devices shall comply with the provisions of ASME B30.20 Below-the-Hook Lifting Devices.

Chapter 3: Operator Training and Operation

Section 2-3.3.1 Scope of Crane Operations

The second sentence of this subsection was revised to read: “The requirements of Section 2-3.3 apply to both dedicated operators, whose primary job is the operation of a crane (cab or pulpit), and nondedicated operators who use a crane (floor or remote) as another tool in performing their job.”

Section 2-3.3.2 General Requirements

Subparagraph (g) was revised to read: “The load, sling, or lifting device (when not reeved into the hoist ropes) shall be seated in the bowl of the hook.”

Section 2-3.3.3 Responsibilities of Management (Owners / Users)

Subparagraph (f) was added, and states: “establish medical and vision criteria, if required, for persons who will operate crane(s).”

Section 2-3.3.5 Responsibilities of Riggers

Subparagraph (l) was added, and includes the following: “verifying that the load, sling, or lifting device (when not reeved into the hoist ropes) is seated in the bowl of the hook.”

Section 2-3.3.6 Responsibilities of Signalpersons

This entire subsection was not included in the 2016 edition, but it outlines the what “a signalperson assigned to a load-handling activity shall, at a minimum, be responsible for:

- Identifying himself / herself as the signalperson to the crane operator before commencing a load handling activity

- Confirming with the operator the method of communication and the associated signals that are to be used during the load-handling activity

- Ensuring that standard, discernible hand or voice signals provided to the operator are in accordance with Section 2-3.6

- Verifying that load-handling activities are stopped if there is a need to give signals to the operator, other than those provided by the established signal system

- Ensuring that telephones, radios or other equipment intended for use as the primary signal system are tested prior to the load-handling activity

- Ensuring that a form of communication is maintained with the operator during all load-handling activities

- Ensuring that all directions given to the operator shall be given from the operator’s perspective (e.g., trolley right)

- Ensuring that each series of voice signals contains three elements stated in the following order:

- Function and direction

- Distance and / or speed

- Function stop

- Ensuring that special signals (when needed) that are not covered by Section 2-3.6 do not conflict with standard signals

- Avoiding giving signal commands that would result in loads being lifted over personnel or moving loads if obstructions are in the path of travel”

Section 2-3.4 Planning for Load Handling Activities

This section was retitled to “Planning for Load Handling Activities.” Previously, the section was titled “Planned Engineered Lifts.”

Section 2-3.4.1 Lift Planning

This section was added, and all subsequent paragraphs were redesignated.

It reads: “Lifting operations are recognized to present risks to personnel or property. Lift planning and oversight shall be tailored to each hoisting operation and shall be sufficient to manage varying conditions and their associated hazards. The information presented in ASME P30.1 provides one method of documenting the planning and oversight necessary to reduce that risk.

“Certain lifting operations are recognized to have increased levels of risk to personnel or property. The criteria to categorize a lift as “critical” on this basis are established by site supervision, project management, a qualified person, or company policies. Lift planning and oversight shall be tailored to each operation and shall be sufficient to manage varying conditions and their associated hazards. ASME P30.1 or an equivalent lift planning tool should be used when the lifting operation is deemed to be “critical”.”

Section 2-3.5 Hoist Limit Devices (Switches)

The second sentence in subparagraph (a) was added, and reads: “If a below-the-hook lifting device is present and will remain on the crane for the duration of the shift, it need not be removed for this test.”

Breaking Down the ASME B30.2 Overhead and Gantry Cranes Updates and Revisions

While several parts of the standard were added, others were either updated or revised.

Updates were made to the following section:

- Section 2-0.3 References

Revisions were made to the following sections:

- Section 2-0.2 Definitions to “lifting device” and “load block”

- Section 2-1.3.1-Foundations and Anchorages

- Section 2-1.3.2-Crane Runways

- Section 2-1.8.1-Trolley Stops

- Section 2-1.8.2-Bridge and Gantry Bumpers

- Section 2-1.8.3-Trolley Bumpers

- Section 2-1.9.1-Bridge Rail Sweeps

- Section 2-1.9.2-Trolley Rail Sweeps

- Section 2-1.13.5-Disconnecting Means

- Section 2-1.13.8-Crane Powered Lifting Devices

- Section 2-2.3.1-Operational Tests

- Section 2-2.3.2-Load Test

- Section 2-3.3.1-Score of Crane Operation

- Section 2-3.3.2-General Requirements

- Section 2-3.3.3-Responsibilities of Management (Owners / Users)

- Section 2-3.3.4-Responsibilities of Crane Operators

- Section 2-3.4-Planning for Load Handling Activities

- Section 2-3.4.2-Planned Engineered Lifts

- Section 2-4.1.2-Crane Maintenance

What Can Mazzella Do to Help You Stay in Compliance with ASME B30.2 Overhead and Gantry Cranes?

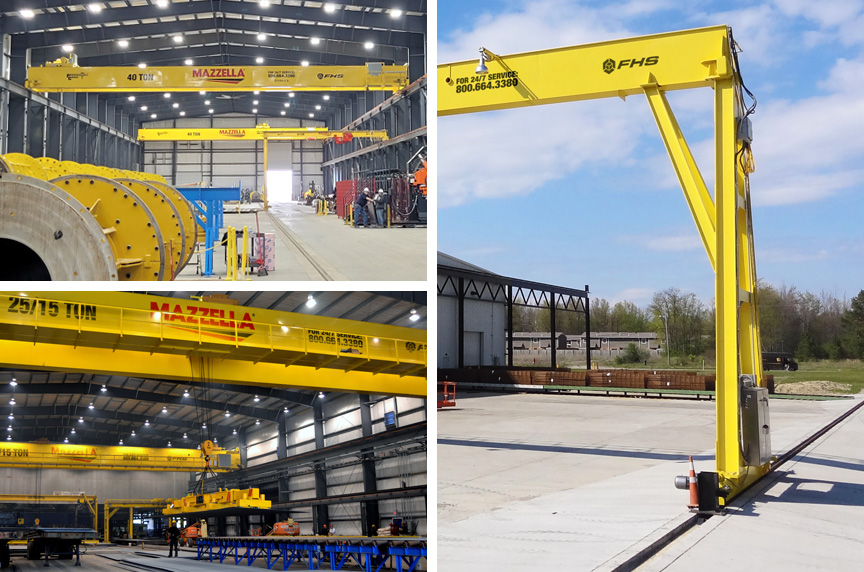

Mazzella is a leading manufacturer of world-class overhead cranes with nearly 70 years of experience. We engineer and build custom solutions ranging from light-duty, economical cranes up to large capacity, high-duty cycle cranes with welded plate-box girders.

Mazzella provides all types of overhead crane systems, including bridge cranes, gantry cranes, workstation cranes, jib cranes, monorail cranes, and more!

We have on-staff engineering and computer-aided design (SolidWorks) capabilities to build customized indoor cranes and runway systems to a lifting capacity in excess of 150 tons.

Our work is done in full compliance with standards from the CMAA (Crane Manufacturers Association of America, Inc.), NEC (the National Electrical Code), OSHA and ASME. We have extensive electrical / control engineering capabilities, as well as AWS certified welders (AWS D1.1 and D14.1).

Call us at 800.644.3380 or click here to contact a lifting specialist to learn more about or purchase a new overhead or gantry crane!

Overhead Cranes & Material Handling

Mazzella is a leading manufacturer of world-class overhead cranes with over 65 years of experience. We engineer and build custom solutions. They include light-duty, economical cranes up to large capacity, high-duty cycle cranes with welded plate-box girders.

We provide all types of overhead crane systems. Those include bridge cranes, gantry cranes, workstation cranes, jib cranes, monorail cranes, and more!

Copyright 2023. Mazzella Companies.