Identification & Markings for Older Below-the-Hook Lifting Devices

It's possible that if you have a below-the-hook lifting device manufactured prior to 2008, it may not be in compliance with today's ASME B30.20 identification and markings requirements. In this article, we try to clear up some of the confusion as to what markings our inspectors look for when performing a periodic below-the-hook device inspection.

Today, all new structural and mechanical below-the-hook lifting devices, and all repaired or modified below-the-hook lifting devices, must conform to both ASME below-the-hook lifting device standards:

- ASME B30.20 – Below-the-Hook Lifting Devices. This standard includes provisions that apply to the marking, construction, installation, inspection, testing, maintenance, and operation of below-the-hook lifting devices.

- ASME BTH-1 – Design of Below-the-Hook Lifting Devices. This standard includes provisions that address the minimum structural and mechanical design and electrical component selection criteria for ASME B30.20.

At Mazzella, we engineer and fabricate standard and custom below-the-hook lifting devices. We also offer comprehensive below-the-hook inspection and repair services that meet and exceed ASME B30.20 requirements. When properly engineered, fabricated, and inspected, a below-the-hook lifting device can stay in service for many years—perhaps even decades.

Our certified inspectors and our team of engineers often encounter older below-the-hook lifting devices that are still in service but may not meet current ASME B30.20 marking and identification requirements. This can lead to a lot of confusion about what does and does not make a lifting device compliant. In this article, we’ll break down the following:

- The introduction of ASME BTH-1-2005 – Design of Below-the-Hook Lifting Devices

- How the introduction of ASME BTH-1-2005 affected the tagging and marking of lifting devices already in service prior to 2008

- The ASME B30.20 Section V: Effective Date clause

- Mazzella’s official statement on pass / fail criteria for ASME B30.20 markings compliance

The Introduction of ASME BTH-1 – Design of Below-the-Hook Lifting Devices

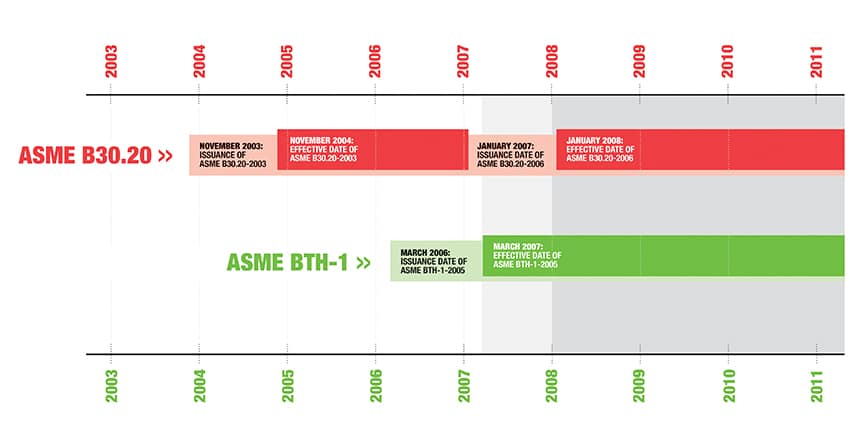

The issuance date of the first ASME BTH-1-2005 standard was March 2006. When a new or revised ASME standard is published, the standard goes into effect one year after its date of issuance—in this case, ASME BTH-1-2005 went into effect in March of 2007.

Two of the major additions that were introduced by ASME BTH-1 were:

- Design Category (static strength criteria)

- Service Class (fatigue life criteria)

ASME BTH-1 Design Categories

ASME BTH-1 specifies that there are two different options that you could have—either Design Category A or Design Category B.

Design Category A – As defined by ASME BTH-1, “Design Category A should be designated when the magnitude and variation of loads applied to the lifter are predictable, and where the loading and environmental conditions are accurately defined or not severe.” Design Category A lifting devices have a nominal design factor of 2:1 and are limited to Service Class 0. Typical applications for these lifters include lifts at slow speeds, a well maintained lifting device, an experienced crane operator, and the control of a lift supervisor.

Design Category B – As defined by ASME BTH-1, should be designated when the magnitude and variation of loads applied to the lifter are not predictable, and where loading and environmental conditions are severe or not accurately defined. This is the most common design category with most below-the-hook lifting devices falling under Design Category B. These lifters can fall under service class 0-4 and require a nominal design factor of 3:1 to the yield strength of the steel.

ASME BTH-1 Service Classes

The Service Class of a lifter is based on the load cycles that a lifter will see in a 24-hour period. The service class 0-4 designation defines the total life cycles a lifter can see based on the specified fatigue life of the lifter.

ASME BTH-1 – Table C2-1: Service Class

| Service Class | Load cycles |

|---|---|

| 0 | 0 – 20,000 |

| 1 | 20,001 – 100,000 |

| 2 | 100,001 – 500,000 |

| 3 | 500,001 – 2,000,000 |

| 4 | Over 2,000,000 |

ASME BTH-1 – Table C2-1: Service Class Life

| Cycles Per Day | Desired Life (1 Year) | Desired Life (5 Years) | Desired Life (10 Years) | Desired Life (20 Years) | Desired Life (30 Years) |

|---|---|---|---|---|---|

| 5 | 0 | 0 | 0 | 1 | 1 |

| 10 | 0 | 0 | 1 | 1 | 2 |

| 25 | 0 | 1 | 1 | 2 | 2 |

| 50 | 0 | 1 | 2 | 2 | 3 |

| 100 | 1 | 2 | 2 | 3 | 3 |

| 200 | 1 | 2 | 3 | 3 | 4 |

| 300 | 2 | 3 | 3 | 4 | 4 |

| 750 | 2 | 3 | 4 | 4 | 4 |

| 1,000 | 2 | 3 | 4 | 4 | 4 |

How the Introduction of ASME BTH-1-2005 Affected the Tagging and Marking of Lifting Devices Already in Service Prior to 2008

Prior to March 2006 (issuance date of ASME BTH-1) there weren’t any published standards that referenced a lifter’s Design Category or Service Class. At that time, ASME B30.20-2003 was the current standard for the marking, construction, and identification of below-the-hook devices.

ASME B30.20-2003 (Section 20-1.2.1: Marking) required the following:

(a) Rated Load. The rated load of the lifting device shall be legibly marked on the main structure or on a tag attached to it where it is visible. If the lifting device is made up of several lifters, each detachable from the group, these lifters shall also be marked with their individual rated loads.

(b) Identification. All new lifting devices shall be marked with, but not limited to, the following information:

- Manufacturer’s name and address

- Serial number

- Lifter weight, if over 100 lbs. (45 kg)

- Rated load

- Cold current (amps)—when applicable

- Rated voltage—when applicable

ASME issued B30.20-2006 in January 2007, which went into effect in January 2008. This standard mandated that all new structural and mechanical below-the-hook lifting devices, and all repaired or modified below-the-hook lifting devices, shall mark the BTH-1 Design Category and BTH-1 Service Class on the main structure, or on a visible tag attached to the device.

After January 2008, any engineered and manufactured lifting device had to conform to ASME B30.20-2006 as well as the new ASME BTH-1-2005 requirements.

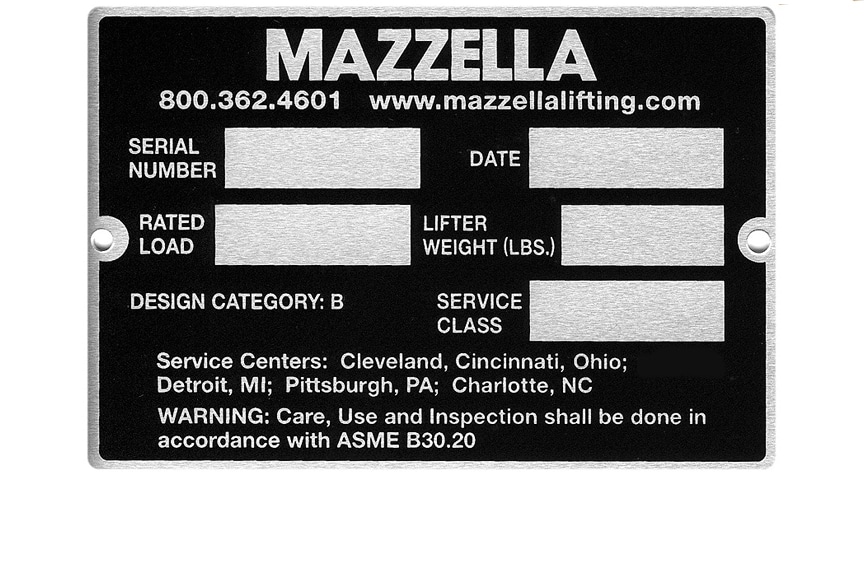

Ever since January 2008, ASME B30.20-2006 (Section 20-1.2.1: Marking) has required the following:

(a) Rated Load. The rated load of the lifting device shall be legibly marked on its main structure or on a tag attached to its main structure where it is visible. If the lifting device is made up of several lifters, each detachable from the group, these lifters shall also be marked with their individual rated loads.

(b) Identification. Structural and mechanical lifting devices shall be marked with, but not limited to, the following information:

- Manufacturer’s name and contact information

- Serial number (unique unit identifier)

- Lifter weight, if over 100 lbs. (45 kg)

- Cold current (amps)—when applicable

- Rated voltage—when applicable

- Rated load [as described in (a)]

- ASME BTH-1 Design Category

- ASME BTH-1 Service Class

(c) Repaired or Altered Lifters. Repaired or altered structural and mechanical lifters shall be provided with identification displaying, but not limited to, the following information:

- Name and contact information of the repairer or alterer

- Repairer’s or alterer’s unit identification

- Lifter weight (if altered)

- Cold current (amps) (if altered)

- Rated voltage (if altered)

- Rated load (if altered) [as described in (a)]

- ASME BTH-1 Design Category (if altered)

- ASME BTH-1 Service Class (if altered)

The ASME B30.20 Section V: Effective Date Clause

However, when ASME B30.20-2006 was published, there was language in Section V: Effective Date that excluded lifting devices manufactured prior to the January 2008 effective date of the B30.20-2006 standard:

“It is not the intent of this Volume of the B30 Standard to require retrofitting of existing equipment. However, when an item is being modified, its performance requirements shall be reviewed relative to the requirements within the current volume. The need to meet the current requirements shall be evaluated by a qualified person selected by the owner (user). Recommended changes shall be made by the owner (user) within 1 year.”

While not saying it explicitly, one could interpret Section V: Effective Date statement as: Any below-the-hook device that was manufactured and in service prior to the effective date of ASME B30.20-2006 (January 2008)—that has not been modified or repaired— would be in compliance with ASME B30.20-2003, Section 20-1.2.1: Marking with the following information marked on the device itself, or on a visible tag attached to the lifter:

- Manufacturer’s name and address

- Serial number

- Lifter weight, if over 100 lbs. (45 kg)

- Rated load

- Cold current (amps)—when applicable

- Rated voltage—when applicable

Mazzella Companies’ Official Statement on Pass / Fail Criteria for ASME B30.20 Markings Compliance

Please note: The information found below is not endorsed by and is not an official stance of The American Society of Mechanical Engineers (ASME). The information below is Mazzella Companies’ interpretation of the ASME B30.20 Section V: Effective Date clause. The information found below is what we use to train our inspectors and our Lifting Specialists to address below-the-hook devices that do not have BTH-1 Design Category or BTH-1 Service Class marked on the device itself, or on a visible tag attached to the device.

When our rigging inspectors are out in the field, the decision to pass or fail a below-the-hook lifting device, based solely on markings, is ultimately an educated decision made by that individual inspector.

If a below-the-hook device is encountered without ASME BTH-1 Design Category and without ASME BTH-1 Service Class markings, our inspectors will use their experience and training to make their best educated decision to pass or fail the device, based on the following criteria:

- The device meets the minimum markings requirements of ASME B30.20-2003

- The device appears to be professionally made by a reputable manufacturer

- The welds appear to be in accordance with ANSI/AWS D14.1 and ASME BTH-1 requirements

- The device does not have any indications of damage that constitute a hazard, including:

- Deformation, cracks, or excessive wear on any part of the lifter

- Loose or missing guards, fasteners, covers, stops, or nameplates

- All functional operating mechanisms and automatic hold-and-release mechanisms for misalignments interfering with operation

- Loose bolts or fasteners

- Cracked or worn gears, pulleys, sheaves, sprockets, bearings, chains, and belts

- Excessive wear of friction pads, linkages, and other mechanical parts

- Excessive wear at hoist hooking points and load support clevises or pins

- Missing or illegible product safety labels

In these instances, our inspectors will inspect each lifting device to the applicable ASME B30.20 standards. Our inspectors are qualified to make an educated PASS or FAIL determination based upon their understanding of the ASME B30.20 Section V: Effective Date clause, and the internal and third-party training that they receive prior to being certified as inspectors.

PASS

If our inspector determines that a device will PASS, they are doing so based on their training, understanding of the ASME B30.20 markings requirements, and the condition of the device at the time of inspection. For certain OSHA and ASME compliance, an engineering drawing or documentation proving that the device was manufactured prior to 2008, may be required.

FAIL – Pending Engineering Review

If there is any question about the physical condition or suitability of a lifting device, our inspectors can FAIL a lifting device pending further engineering review. For certain OSHA and ASME compliance, an engineering drawing or documentation proving that the device was manufactured prior to 2008, may be required.

Members of Mazzella’s rigging inspection, engineered products, and marketing teams worked together to create this document. This team was led by Lili Radu, P.E.—Chief Engineer, Mazzella—who contributed her expertise to the creation of this document.

As a P.E. for the Engineered Products and Below-the-Hook team, and as a member of the ASME B30.20 Standards Committee, Lili brought a unique and professional perspective to this project. Her understanding and contribution to ASME standards helped shape the language, format, and presentation of this document.

The goal of this team was to review the applicable ASME B30.20 and ASME BTH-1 standards and develop an official company stance on acceptable markings and identification compliance for older below-the-hook lifting devices. This official document can then be used in a number of different ways, including:

- To help train our rigging inspection, customer service, and outside sales teams

- To help educate existing or future customers on the inspection criteria our inspectors will use for older below-the-hook lifting devices

- To help educate others in the industry who may have similar questions or confusion about this topic

If you have any questions about below-the-hook inspections, lifting device markings or repair, or want to speak with a specialist about your lifting application, please do not hesitate to contact us.

Copyright 2019. Mazzella Companies.