How Do You Safely Lift Off-Center Loads?

How do you safely lift an off-center load? There are several ways to safely make an overhead lift, even if that load has an off-center center of gravity.

How do you lift a load when the weight is not evenly distributed?

Lifting an off-center load incorrectly is extremely risky and dangerous. Sometimes, it is easy to find the center of gravity. Other times, it can be more complicated.

If you look at one load to be lifted, you may easily determine that the center of gravity, or its balance point, would be directly in the middle. However, if you have another object that is weighted more to one side than the other, the center of gravity, or balance point, is not going to be exactly in the middle.

If you were to lift in the same manner as you lifted a perfectly centered load, the load would tilt. Also, the load could slip out of the rigging as it is being lifted from a resting position. That could cause property damage, or even injury and death to workers by making an unknown and uncontrolled movement.

In order to prevent that from happening, you really need to understand where the center of gravity is and what the best piece of lifting equipment is to address it.

To answer the question of how to safely lift an off-center load, we reached out to Dan Mongan, senior sales engineer for Caldwell / J.C. Renfroe Lifting Solutions in Rockford, Illinois.

In this article, you will learn how to:

- Lift a centered load

- Find the center of gravity

- Rig a load with an unknown center of gravity

- Utilize tools needed to adjust for center of gravity

- Attach pick points above the center of gravity

How Do You Lift a Centered Load?

In this example, you’re using a spreader beam that has weight on each end with a balanced center of gravity. With an equal load on each end, it stands to reason the beam hangs level. However, in reality, not everything is perfectly level. Typically, if a lift is within 5°, that’s reasonable, but some applications may have to be more precise.

Maybe you’re assembling an object that has to be perfectly level or aligned with something else. In those cases, you’ll need to look at other equipment to make sure it’s perfectly level. That may require making multiple adjustments and test lifts to find the true center of gravity.

How Do You Find the Center of Gravity?

If you have an offset center of gravity and the adjustable hardware is still centered, maintaining load control will be difficult. Many dangerous situations can happen, including but not limited to:

- Incorrect loading of the lifter

- The load moved in an unexpected manner / direction

No matter what the lifting device is, no matter what’s going on between the hook and the load, the key is getting the crane hook directly above the center of gravity. That’s the golden rule. That’s how Caldwell simplifies thinking.

You always want to make sure the crane hook is over the center of gravity. In order to get the crane hook over the center of gravity, you want to move the crane hook closer to the heavier end. With certain Caldwell lifting beams, you’ll be able to adjust and reattach the rigging hardware for the crane hook closer to the heavier end of the load. Also, you may be able to adjust the rigging hardware that connects the beam to the load itself to get the hook closer to the center of gravity.

How Do You Rig a Load with an Unknown Center of Gravity?

In many situations, the center of gravity for a load is not known. However, finding that center of gravity is not as difficult as you might thing.

It could be as simple as making test lifts. These test lifts are done to determine where you should position your rigging gear to create a level lift.

At the beginning of the lift, you slightly raise up a load only a couple inches. Maybe just one end comes off the ground while the other stays on the ground. That helps you identify which end of the load is the heaviest and allows you to make adjustments to your rigging to balance and center the load.

You may make this adjustment multiple times in some cases until you’ve proven the load will be lifted level and safely.

What Tools Are Needed To Adjust for Center of Gravity?

In addition to lifting off-center loads using Caldwell’s DuraLite model, which allows for shackle and bail adjustment positions, there are several options.

Mazzella offers lifting beams and spreader bars which have adjustable plate bails. The bail is where you connect your crane hook. With an attached pin that can simply be pulled, the bail can be moved to multiple positions to account for the load’s center of gravity.

During the test lift with the bail position right in the middle, you may notice one end raises up, that tells you the other end is heavier. To level off the lift after it has been returned to a resting position on the ground, you pull the pin, move the bail to the next adjustment point, and then, make another test lift.

If that adjustment works and the lift is level, you should be good to start lifting loads. However, if not, more adjustments and test lifts would be needed to find your center of gravity.

Chain Slings

Along with having adjustable beams, there are other ways of adjusting your rigging gear to account for center of gravity.

Chain slings can be connected directly to the load, or to a spreader beam that’s designed to accommodate for potential adjustments.

These adjustments could be as simple as using a grab hook and shortening one chain leg. When you do that and you make a test lift, it moves the crane hook above the center of gravity of the load so you can make a level lift.

Under the Gunnebo brand, Crosby manufactures the GrabiQ Chain Sling.

By switching from Grade 80 to Grade 100 chain, Gunnebo Industries branded products increased the working load limit by 25 percent compared to prior systems.

The “all-in-one” compact top link Master Grab Duo (MGD), which is one of Gunnebo Industries’ top-selling products, allows for easy adjustment of the length of the legs, as well as creating leg loops to lift bars or other objects that lack connection points.

Only one component is needed to create a chain sling solution with the same function as a traditional system using seven components. With fewer components, lifting operations also become much more effective, which saves both time and money.

How Do You Attach Pick Points Above the Center of Gravity?

What you need to do first, as a rigger or crane operator, is just look at the load and think: “What is the chance the center of gravity is on-center?” If this is going to be an issue, you’ll need to make test lifts to identify a type of rigging that can allow you to get the crane hook over the center of gravity.

The goal is really simple. You have to get the crane hook above the center of gravity of a load, no matter what rigging is used between the hook and the load. It could be anything including, but not limited to:

- Lifting beams

- Spreader beams

- Adjustable chain slings

The other important thing to remember with center of gravity is where it is located height-wise in relationship to where your rigging connects to.

Example: If you connect to the top of a table, it’s going to be a very stable lift because the center of gravity is somewhere below the top of the table. However, if you connect toward the legs of the table, it’s very unstable. It could roll one way or the other and cause the lift to fail because the center of gravity is above the lifting points.

How Can Mazzella Help You with Your Lifting and Rigging Needs?

At Mazzella, we have you covered when it comes to all of your lifting and rigging needs. With our ready stock inventory, we offer all industries a variety of lifting and rigging devices.

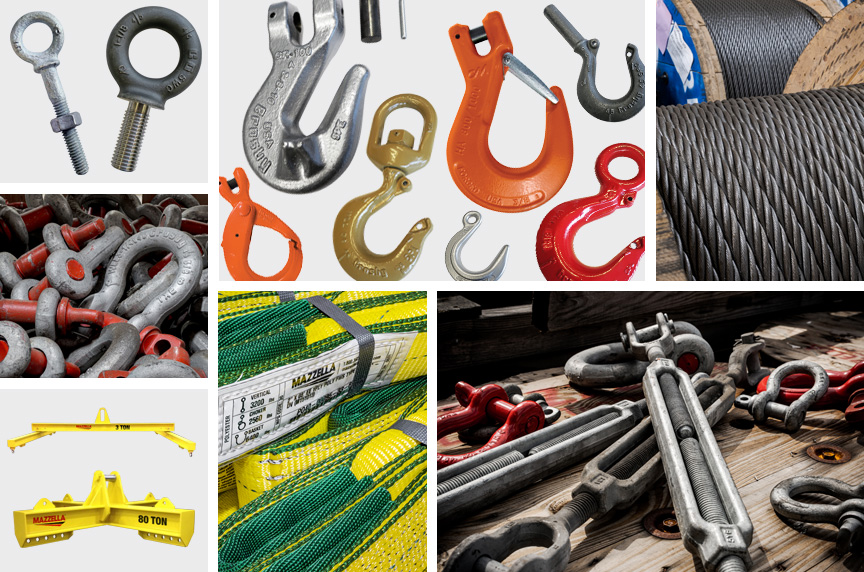

Hardware

We offer one of the largest and most complete inventories of rigging and lifting products in the country from some of the largest manufacturers in the world. Some of the products we stock are:

- Shackles—all types, sizes, and finishes from 1/4 ton to over 1,000 tons

- Hoist rings—standard and metric

- Eyebolts—forged, metric, and stainless steel

- Hooks—swivel, eye, choker, self-locking, and weld-on

- Master rings / links—all sizes, types and finishes

- Turnbuckles and swivels

Rigging Training

If you require a specific training course for OSHA (Occupational Safety and Health Administration) compliance for slings, hoists and / or rigging hardware, Mazzella can assist you in creating a safe and reliable workplace.

Our rigging training focuses on:

- Overhead cranes

- Below-the-hook lifters

- Lifting slings

- Rigging hardware

- Wire rope

All Mazzella trainers have been accredited by our company through training from a third-party company (Industrial Training International, Inc.), Mazzella Companies’ internal Train-the-Trainer program, and are trained on standards set forth by OSHA and ASME (the American Society of Mechanical Engineers).

Also, we provide site assessments. The purpose of an assessment is to systematically observe and record your lifting and rigging procedures, equipment, and records. This is not an inspection, but rather, a general assessment by which opportunities for improvement may be identified.

Rigging Inspection Services

OSHA 1910.184, ASME B30.9 Slings, ASME B30.20 Below-the-Hook Lifting Devices, ASME B30.26 Rigging Hardware & ANSI Z359 require…

Periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions.

Our rigging inspectors are certified to make sure your products meet OSHA and ASME requirements. Also, we provide personal fall protection inspections and basic level non-destructive testing (NDT) inspections to support our visual inspections.

Call us at 800.362.4601 or click here if you need inspections for rigging hardware, training, or any of our other services.

Overhead Cranes & Material Handling

Mazzella is a leading manufacturer of world-class overhead cranes with over 65 years of experience. We engineer and build custom solutions ranging from light-duty, economical cranes up to large capacity, high-duty cycle cranes with welded plate-box girders.

Copyright 2023. Mazzella Companies.