Carbon vs. Alloy Chain: What’s the Difference and Why It Matters

This article breaks down the differences between carbon and alloy chain, which type is used for overhead lifting, and how to choose the right one for your application.

Estimated reading time: 10 minutes

Watch the full video on the Lifting & Rigging Channel.

Every year, thousands of rigging and lifting operations depend on chains to get the job done. But not all chains are created equal, and using the wrong type can lead to damaged equipment, failed lifts, or serious injury.

If you’ve ever searched online for “lifting chain,” you’ve probably come across carbon chain and alloy chain options that look almost identical. The difference isn’t easy to spot, but it’s one of the most important distinctions you can make when choosing rigging equipment.

In this article, we’ll break down the real differences between carbon and alloy chain, explain which type is approved for overhead lifting, and help you make an informed, compliant, and safe purchasing decision.

Table of contents

- What’s the Difference Between Carbon and Alloy Chain?

- Which Type of Chain Is Stronger?

- Can Carbon Chain Ever Be Used for Overhead Lifting?

- When Should You Use Carbon Chain vs. Alloy Chain?

- Why Is Alloy Chain More Expensive Than Carbon Chain?

- Can You Tell the Difference Between Carbon and Alloy Chains by Looking at It?

- What Questions Should You Ask Before Buying Chain?

- How to Spot Unsafe or Misused Chain

- Final Thoughts: Use the Right Chain for the Job

- Frequently Asked Questions About Carbon Chains and Alloy Chains

What’s the Difference Between Carbon and Alloy Chain?

Both carbon and alloy chains start with steel, but that’s where the similarities end.

Carbon chain is made from plain carbon steel with very little alloy content. It offers sufficient strength for general industrial or commercial purposes, such as tie-downs or light-duty applications. However, it lacks the ductility and elongation capacity required for lifting or other dynamic load-bearing uses, where flexibility and shock absorption are critical.

Alloy chain, by contrast, is engineered from steel enriched with elements such as nickel, chromium, and molybdenum. Combined with a precisely controlled heat-treatment process, these additions produce a material with exceptional strength, toughness, and elasticity. Alloy chain can stretch slightly under load, absorb shock, and return to its original shape without permanent deformation or failure.

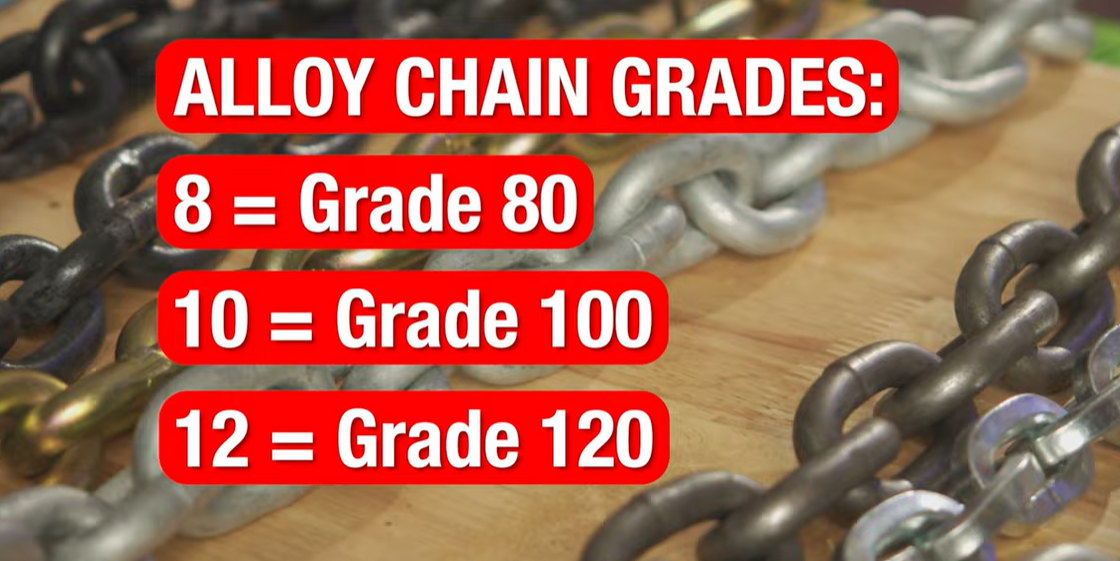

Ultimately, the difference lies in both the composition of the steel and the heat treatment it undergoes. This transformation process turns alloy steel into a lifting-grade material, meeting the demanding mechanical standards of Grades 80, 100, and 120.

Which Type of Chain Is Stronger?

When it comes to tensile strength and working load limit (WLL), alloy chain far outperforms carbon chain.

A Grade 120 alloy chain achieves a tensile strength of approximately 120 decanewtons per square millimeter of cross-sectional area. By comparison, even the strongest carbon chain, such as Grade 70, reaches only around 70 decanewtons, meaning the alloy version is roughly 70% stronger.

But strength is only part of the story. Alloy chain also provides controlled elongation, stretching up to 20% before breaking. This ductility acts as a built-in safety feature: if a lift becomes overloaded, the chain visibly elongates, alerting the operator before failure occurs.

Carbon chain, by contrast, lacks this predictable behavior. It does also stretch, but it tends to fracture suddenly and without warning when overloaded, offering no visual sign of distress. This is a key reason why it should never be used for overhead lifting.

Can Carbon Chain Ever Be Used for Overhead Lifting?

Both the Occupational Safety and Health Administration (OSHA 29 CFR 1910) and the National Association of Chain Manufacturers (NACM) clearly state that only alloy chain is approved for lifting applications.

These regulations exist for good reason: carbon chain lacks the mechanical strength, ductility, and controlled elongation required to absorb shock loads or withstand the stresses of dynamic lifting.

Even if a carbon chain were heat-treated to raise its strength, the result would be a harder but far more brittle material that could fail suddenly without warning.

When lifting overhead, alloy chain is the only legal and compliant choice.

When Should You Use Carbon Chain vs. Alloy Chain?

Each chain type has its place. The key is matching the chain to the right job.

| Chain Type | Common Grades | Typical Applications | Not For |

| Carbon Chain | Grade 30, 43, 70 | Tie-downs, fencing, decorative uses, anchors, marine and towing applications | Any overhead lifting or rigging |

| Alloy Chain | Grade 80, 100, 120 | Overhead lifting, rigging, hoisting, material handling, crane and hoist assemblies | Tie-downs or towing |

Carbon chain excels in general-purpose applications such as load securement, boat anchoring, or fence construction. Alloy chain, by contrast, is specifically engineered for high-risk, high-load environments where strength, ductility, and reliability directly impact safety and performance.

Using carbon chain for any lifting application is a direct violation of OSHA regulations.

Conversely, using alloy lifting chain for non-lifting tasks is typically unnecessary and often overkill. Applications like load tie-downs, towing, barrier chains, construction bracing, or agricultural work don’t demand the certified strength, elongation control, or testing that alloy chains undergo.

In these situations, carbon or transport-grade chains (Grades 43 or 70) offer a more practical and cost-effective solution, unless you specifically need to reduce chain size or weight while maintaining high strength.

Why Is Alloy Chain More Expensive Than Carbon Chain?

The higher cost of alloy chain comes down to materials and manufacturing.

Alloy chain is made from steel enriched with nickel, chromium, and molybdenum. These elements enhance strength, fatigue resistance, and elongation, but they also increase the cost of production.

After cutting, bending, and flash butt welding, each link undergoes precise heat treatment and multiple testing stages to ensure it meets the exacting mechanical and elongation requirements of Grades 80, 100, or 120.

Think of it as the difference between basic steel and premium performance steel. The raw materials, heat treatment, and certification process all add to the price, but they also guarantee that every link will perform safely, predictably, and consistently under demanding loads.

Can You Tell the Difference Between Carbon and Alloy Chains by Looking at It?

Sometimes, but not always.

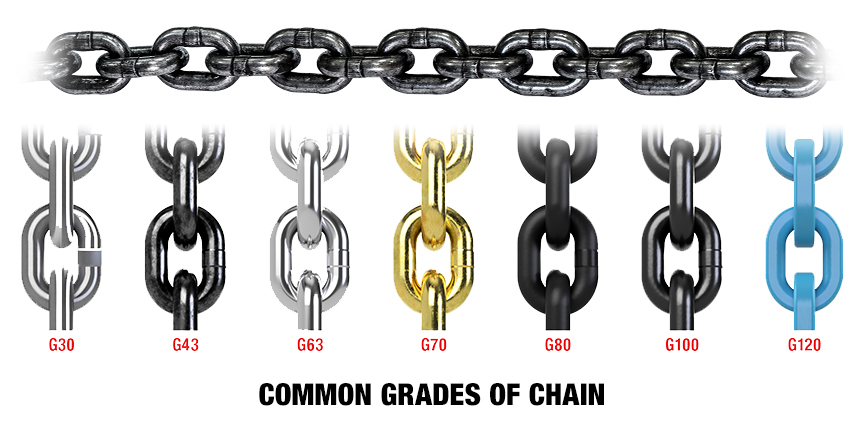

While color and coating can sometimes hint at a chain’s grade, they are not reliable identifiers of what type of chain you’re actually holding.

- Gold-colored chain is most often Grade 70, a transport chain, not a lifting chain.

- Blue or black chain is typically Grade 100 or Grade 120, both engineered for lifting.

- Hot-dip galvanized chain is almost always carbon steel, since the galvanizing process can weaken alloy chain by reducing its strength and elongation.

The only dependable way to identify a chain is by checking its markings and manufacturer’s ID tag.

If the links are stamped G80, G100, or G120, you’re holding a lifting-rated alloy chain.

If the markings read G30, G43, or G70, it’s a carbon or transport chain, suitable for tie-down or towing, but never for lifting.

What Questions Should You Ask Before Buying Chain?

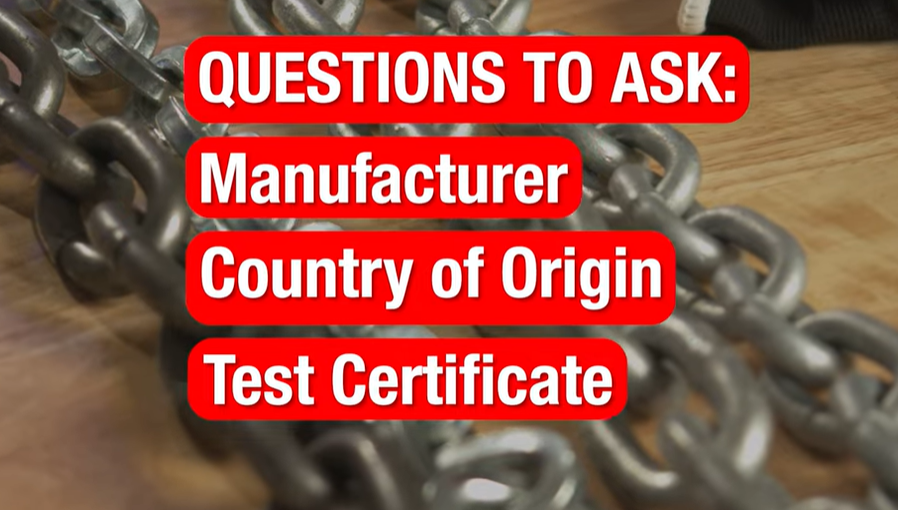

If you’re purchasing chain for any lifting or safety-critical application, there are three essential questions you should always ask your supplier:

Who is the manufacturer?

Reputable chain producers provide traceable link markings and verifiable test documentation for every batch.

Where was it made?

Knowing the country or region of origin helps ensure the product complies with NACM and OSHA standards.

Can you provide a test certificate?

Certified lifting chain is always accompanied by a test certificate confirming compliance with Grade 80, 100, or 120 specifications.

Asking these questions protects you from counterfeit or substandard products and ensures the chain you buy meets the performance, traceability, and safety requirements your job depends on.

The Risks of Using the Wrong Chain

One of the most common (and dangerous) misconceptions in rigging is assuming that all chain is the same.

Someone might buy a carbon chain online because it’s cheaper, or grab a transport chain from a hardware store for a quick lift. That decision can be costly and unsafe.

Carbon chain is not engineered for lifting. Under dynamic or shock loads, it can fail suddenly without warning, potentially causing equipment damage, serious injury, or even fatal accidents. The few dollars saved per foot are never worth the risk.

The same logic applies to tie-down and transport work. If you’re securing cargo on a truck or trailer, a Grade 70 carbon chain is perfectly suitable. But if you’re lifting, hoisting, or supporting a load overhead, the only safe and compliant choice is an alloy lifting chain.

How to Spot Unsafe or Misused Chain

When inspecting chain in the field, pay close attention to the following points:

1. Markings – Verify the grade and manufacturer’s ID stamped on the links. This confirms you’re working with the correct, traceable chain.

2. Elongation – Any visible stretching, necking, or deformation means the chain has been overloaded and must be removed from service immediately.

3. Coatings – If the chain appears gold-colored or hot-dip galvanized, it’s most likely not lifting-grade.

4. ID Tags – Every rigging assembly should include a tag listing the grade, size, working load limit (WLL), and manufacturer information.

Elongation itself isn’t the danger. It’s the warning sign that the chain has already exceeded its safe working limit and must be replaced.

Final Thoughts: Use the Right Chain for the Job

Every chain has a purpose, and choosing the wrong type for your application can have serious consequences.

Carbon chain is affordable, versatile, and ideal for non-lifting applications like towing, anchoring, or load securement.

Alloy chain, on the other hand, is engineered for lifting, rigging, and hoisting.

If you’re ever unsure which chain is right for the job, check the markings, review the test documentation, and consult a qualified rigging professional. When it comes to overhead lifting, the chain you choose is a crucial component to keeping your workers safe.

At Mazzella, we supply only certified alloy lifting chain and assemblies that meet or exceed OSHA, ASME, and NACM standards. If you have questions about chain selection, grade requirements, or proper sizing, reach out to your local Mazzella branch or request a consultation. Our experts are here to help you lift safely and with confidence.

Frequently Asked Questions About Carbon Chains and Alloy Chains

Copyright 2025. Mazzella Companies.