Which Slingmax® Sling Protection Product Is Right for You?

This article, which is based off our collaborative video with Slingmax®, will explain and compare the different types of Slingmax® sling protection offerings. We will review, among other things, the ideal applications for each.

Many riggers underestimate how important it is to pair your lifting slings with an engineered sling protection solution. Whether you’re a Safety Manager or in charge of operations, the market is filled with all kinds of sling protection offerings, and you may be overwhelmed with deciding which one best fits your application.

While some riggers and operators think sling protection is optional, every lift should be viewed as critical, regardless of the weight of the load or the type of sling being used—especially if you are using synthetic lifting slings. It’s always best practice to have your synthetic sling in one hand and your cut protection in the other.

Thankfully, our partners at Slingmax Rigging Solutions have been a leader in designing and engineering sling protection products for decades and have multiple product lines available.

This article, which is based off our collaborative video with Slingmax®, will explain and compare the different types of Slingmax® sling protection offerings. We will review, among other things, the ideal applications for each. We will also answer important questions you must answer during your research process, such as:

What Is the Difference Between Cut and Abrasion Protection?

As discussed in previous articles, knowing the difference between cut protection and abrasion protection is crucial for deciding the best sling protection for your application

Cut protection is designed to protect the load-bearing core yarn of your lifting sling when rigged over an edge.

Cut protection is needed when rigging over any edge. Even edges that don’t look razor sharp can cause serious damage to your sling once put under tension. In fact, ASME B30.9 standards dropped the word sharp.

Meanwhile, abrasion protection is designed to protect the outer jacket from rough surfaces, such as concrete or metal.

Where Should You Use Cut Protection Over Abrasion Protection, Vice Versa?

Abrasion protection would be best suited for lifting large stones or concrete slabs. Consequently, they can be very beneficial for construction and excavation companies, rock quarries, and mining operations.

Cut protection also has a place in construction. We also see cut protection products lifting steel beams and loading and unloading steel coils at mills and processing plants.

While some riggers and operators view synthetic lifting slings as simple and disposable items, pairing them with one of the below sling protection offerings can extend their lifespan and make them usable in applications historically meant for wire rope slings and alloy chain slings.

Can Cut Protection and Abrasion Protection Offerings Be Used Interchangeably?

No. Cut protection sleeves are specifically engineered, designed, and tested to protect the sleeve from cuts. The same logic applies to Slingmax’s abrasion protection offerings.

What are Slingmax’s Cut Protection Products?

CornerMax® Pads

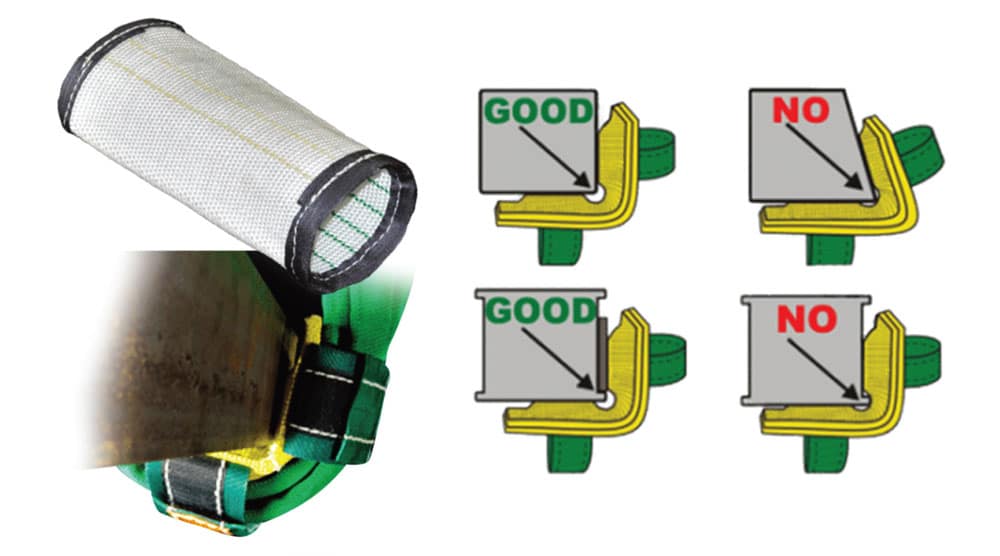

Slingmax’s CornerMax® Pads were designed to create a “tunnel” of cut protection, where the lifting sling doesn’t contact the load’s edges. The pad is designed to be used on loads with a 90° angle, so the load will sit on the raised area of the pad and not touch the sling at all.

CornerMax® Sleeve

The CornerMax® Sleeve is one of Slingmax’s most popular sling protection products. Made from a High Modulus Polyethylene fiber (HMPE) and a tight weave configuration, CornerMax® Sleeves are incredibly durable and can withstand harsh environments.

In fact, CornerMax® Sleeves can reach 25,000 pounds per square inch of sling width, which is exceptionally high compared to other product offerings.

Unlike cut-protection pads, which are ideal for loads with 90° straight edges, the CornerMax® Sleeve can form around most geometric shapes. They can be used on any flat web sling, polyester roundsling, or synthetic lifting sling on your job site. But since the sleeve was designed with synthetic material in mind, CornerMax® Sleeves would not be ideal for wire rope or chain lifting slings.

Which One Is Best for You?

Both the CornerMax® Sleeve and the corner max pad are rated for 25,000 pounds per usable inch of sling width, so there’s no difference regarding what they can handle and protect.

Your application will matter most when deciding which one is right for you. Are you lifting loads at a 90° angle, or does the load have a curved surface like a roll of steel or aluminum?

Is Cut Protection Customizable?

There are plenty of customization offerings for the CornerMax ® Sleeve. You can use Velcro to make the sleeves removeable. You’re also able to stitch corner max sleeves directly onto your Slingmax Twin-Path® path sling. The CornerMax ® pad, however, doesn’t have significant customization offerings, but it is adjustable.

Some customers have asked if it’s possible to make an entire sling jacket out of the CornerMax ® Sleeve. While it seems reasonable, it’s very expensive material and would cost you a fortune to make an entire lifting sling out of it.

What are SlingMax’s Abrasion Protection Products?

Spider Sleeve

The newest Slingmax product on the market is the Spider Sleeve. Like the CornerMax Sleeve, the Spider Sleeve is made from HMPE fibers that are tightly woven to enhance its strength. This material makes the Spider Sleeve a great choice for challenging lifting applications.

It’s light and has a low coefficient of friction (COF). This allows the sling jacket to easily glide over itself or any rough hardware or surfaces that could damage the sling. The sleeve also prevents jacket damage when the sling is tightly choked.

Synthetic Armor Pads

A popular abrasion protection option, the synthetic armor is a pad made from the same material as the Twin-Path® Path sling. They are used to protect finished or unfinished loads from marring and can be made to fit most lengths or widths. The pads are also made with Kevlar to give it an extra layer of abrasion protection. You can think of the armor pad as a sacrificial layer of protection for the sling’s load-bearing core yarns.

Synthetic armor pads are ideal for lifting concrete beams or structures—any load with rough surfaces. And depending on your preference, you can attach Velcro on it to make it removeable, or you can permanently stitch it onto the lifting sling.

Another good application for synthetic armor pads is protecting the load from the sling itself. If you’re using a wire rope sling, and you don’t want to mar the surface of the load, you can use the pad to protect the load from the sling.

How are They Different?

The synthetic armor pad is designed as an all-purpose protection pad for lifting slings on a job site. The synthetic spider sleeve, meanwhile, would be better for engineered lifts where you may have tight hardware or a choker hitch, allowing the sling to easily release so you can keep using it repeatedly.

Can You Use Homemade Sling Protection?

One of the biggest pushbacks we see from riggers is that manufactured sling protection products are unnecessary and a waste of money. In their shop, they will sometimes use flip flops, work gloves, or old fire hoses as makeshift sling protection.

According to ASME B30.9 Slings standards, a sling user needs to work with the sling manufacturer to determine what is an appropriate level of cut or abrasion protection for their rigging. No credible lifting sling manufacturer would ever recommend using flip flops or gloves as protection.

Instead, engineered sling protection products, whether cut or abrasion, have gone through countless hours of load testing and design alterations to ensure they can withstand the toughest lifts in a variety of environments. Using homemade sling protection is a gamble on the safety of your workers and the load.

What if Your Sling Protection Gets Damaged?

First, you should inspect your sling protection before any lift, just like the lifting slings. If the sling protection is damaged, it should be removed from service.

If your sling has protection stitch directly to the jacket, you can submit it to the manufacturer so it can be properly repaired and inspected.

Why Should You Invest in an Engineered Sling Protection Solution?

Safety is the most important priority on any job site. For some, spending the extra money on engineered sling protection products seems unnecessary.

But companies should invest in engineered sling protection because you know exactly what you’re getting with that product. If you use a glove or an old sling or a piece of rubber, you don’t know how much it’s actually protecting that sling, and all you’re doing is putting your workers’ lives at risk.

Any company looking to improve worker safety, extend the life of their lifting slings, and better protect their loads would benefit from owning any engineered sling protection products, and we hope this article helps you decide which one is best for your application.

Engineered sling protection products are backed by engineering data and hours of load testing, so you know exactly how much protection you’re getting out of that piece of equipment on your round sling.

Picking the right sling protection product is all about understanding your application, and any Slingmax-accredited dealer, including Mazzella, can help you during that process.

With state-of-the-art solutions from our trusted partners at Slingmax, you will have peace of mind regarding the safety of your lifting sling and workers. Whether you need cut or abrasion protection, we’re here to help you find the right sling protection for your application. Contact one of our Lifting and Rigging Specialists to learn more.

Copyright 2024. Mazzella Companies.