From Need to Delivery, Everything You Need to Know to Buy a BTH Device

Engineering a below-the-hook device is one thing, but knowing about the process, timelines, approval drawings is another. Using an accredited third-party company is the way to guarantee you are getting a quality BTH device that is in compliance with the ASME B30.20 and ASME BTH-1 standards.

There is no margin for error when overhead lifting is required on a job site.

The slightest miscalculation in any part of an overhead lift can turn an ordinary day into a catastrophic one that results in injury and / or death. That is why standards exist for safety, as well as the equipment used in performing those lifts, including below-the-hook lifting devices.

When conducting overhead lifts, it’s always good to take your needs to third-party companies that design, manufacture, and distribute below-the-hook devices on a day-in, day-out basis. It gives you peace of mind of having a device that was expertly engineered and fabricated specifically for your lifting application.

In this article, you will learn more about the process of purchasing a below-the-hook lifting device, including:

- What standards BTH devices are manufactured to

- How to order a custom BTH device

- What the lead time is for a BTH device

- How do you get a repair on a BTH device

- Why you should go with a third-party company

What Standards Are BTH Devices Designed to Meet?

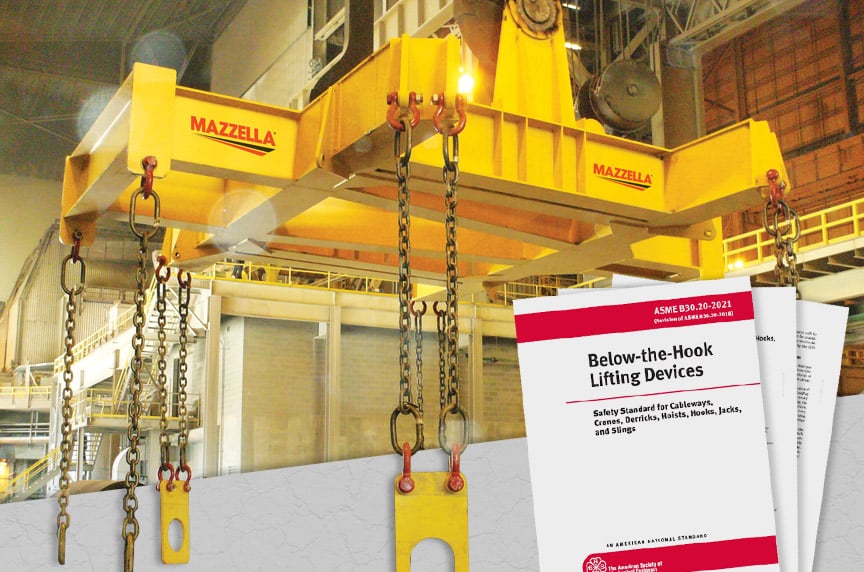

The American Society of Mechanical Engineers (ASME) have two standards that below-the-hook lifting devices must adhere to:

- ASME B30.20 Below-the-Hook Lifting Devices

- ASME BTH-1 Design of Below-the-Hook Lifting Devices

ASME B30.20 outlines the tagging, load testing, maintenance, and inspection requirements, removal criteria, repairs and operator responsibilities for six types of below-the-hook lifting devices.

This standard covers:

- Structural and mechanical lifting devices

- Vacuum devices

- Close proximity operated lifting magnets

- Remotely operated lifting magnets

- Scrap and material-handling grapples

- Clamps

The ASME BTH-1 standard digs deeper and talks more on the engineering side with safety factors, design categories, and service classes. It gets into the minute details of what each lifter needs to meet requirements from the engineering side.

Mazzella has years of expertise and understanding of the standards. Actually, we have engineers that sit on the ASME B30 committees, which are responsible for writing the standards for the manufacture and operation of below-the-hook lifting devices. Additionally, we have all the appropriate insurances and everything to be able to provide you with a device that is certified, and backed by professional engineers and meets the industry design standards.

What’s the Process for Ordering a Custom BTH Device?

The process of ordering a Mazzella below-the-hook lifting device is initiated either by a customer reaching out directly, or a sales representative making an on-site visit and discovering there is a need for new lifting equipment.

Safety and efficiency are the two main reasons for using a below-the-hook lifting device in conjunction with your crane and rigging equipment. Sometimes, using a traditional wire rope sling, alloy chain sling, or synthetic sling just isn’t enough to safely and securely move a load from one location to another.

Often, a customer who is already using some type of lifting sling, or a variety of slings, will approach a manufacturer to develop a custom lifting device for their lifting application. It may be because it’s taking too long to secure their load using traditional rigging, or it may be due to the size, shape, or weight of the load, and they don’t feel their current method is the safest or most effective.

An accident or near miss may be another reason to convert to a custom below-the-hook lifting solution. If the materials you are trying to move just don’t look right when they get up into the air, or you don’t feel that your load is secure enough—or worse yet, you’ve actually experienced a rigging failure—then it’s probably time to consult with an expert and see if they can help engineer a solution to keep your employees safe and your loads secure.

Initial Steps

Following up on the initial inquiry, we’re going to send out a technical product specialist focused in below-the-hook lifting devices to:

- Review your lifting application

- Discuss our design and engineering processes

- Make sure we have a full understanding of what you’re trying to achieve in this lift

- Understand the parameters of the project

- Gather some of the measurements of what you’re lifting

- Identify any restrictions around what you may be lifting

This information will be put onto a front-load sheet, which will then be given to our engineering team. From there, our engineering team is going to work with our estimation team to put together a quote and approval drawings. Once the quote’s provided to you, and you sign off, our engineering department needs to receive a purchase order before beginning the manufacturing process.

Approval Drawings

Engineering will start putting together approval drawings with critical dimensions and measurements detailed on the drawings. Then, we ask you and the technical product specialist to go over the drawings, and outline how the device(s) will be used in the field.

This step is to ensure that you get what you need to make safe lifts, and verify the design and measurements of the device(s) will work in the application and be the best piece for the application.

Fabrication

Once all that is agreed upon and you sign off on the approval drawings, the manufacturing process gets underway. We receive the raw materials into our facility, and then, fabricate your below-the-hook lifting device. If we are load testing the below-the-hook lifting device, we’ll conduct the test, and when it passes, paint it, and then, ship it off to you.

Upon its arrival, and after you do an initial inspection, you can put the below-the-hook lifting device into service.

What’s the Lead Time for a Custom BTH Device?

Lead time can vary depending on the complexity of the project.

If your project falls into one of our standard product offerings, where it’s not a complex build that’s going to require machining and secondary processes to it, we’re typically anywhere between six to 10 weeks from approval to delivery.

When we start to get into some of the bigger lifting devices, for example mill duty items, they will require more time. First, they need to be fabricated, possibly go out for machining, and have secondary processes done to them. Getting one of these devices completed could take anywhere between 10 to 24 weeks.

What If My BTH Device Gets Damaged?

If you get a device from Mazzella, and for whatever reason, damage happens to the device, we immediately want you to contact us. We’ll pull that device out of your facility, and then, investigate what happened so we can have a full understanding of what might have caused the device to fail.

Reasons for failure could include product misuse, a manufacturing flaw, misunderstanding of your application, or forces applied to the device that weren’t considered during the design and engineering stages. We’ll take all that into account. If the device has been in service for years and experienced a break, we’ll bring the device back to our facility, inspect the entire lifter, repair it (if possible) and get it back into the field to use.

***We recommend that you DO NOT work on or repair any of our below-the-hook lifting devices in the field. Doing so could void the manufacturer’s warranty, and shift the liabilities of that device in the case of a failure to your company.

Why Is It Important to Go with an Accredited Company?

If an accident happens, and it’s a recordable one that’s going to bring OSHA (the Occupational Safety and Health Administration), they will comb through every detail to make sure your below-the-hook device meets the standard’s requirements. From our experience, when OSHA inspectors go in and they find devices do not have all the proper markings required by ASME B30.20, they start to question it and ask for the information about the lifting device. When customers don’t have the proper documentation, that is when fines will be issued.

Documentation includes the approval drawings, engineering designs, and inspection reports.

In addition to OSHA fines, you stand the chance for legal ramifications from either the individual that was injured, or if it was a contractor from a different company, that organization could pursue damages. If an in-house engineer did drawings for a device to be manufactured, that engineer could be held personally responsible, too.

Simply put, designing and using in-house below-the-hook lifting devices could put everyone in your company into a tough spot they could have avoided because there are companies who offer lifting solutions that are certified to meet all of the standards and requirements, and are designed to do specific tasks.

What Comes with an Engineered BTH Device?

When you purchase a Mazzella engineered below-the-hook lifting device, it’s going to come with all the required tagging and markings that meet the ASME B30.20 standard. It’s going to have all the engineering behind it that meets the ASME BTH-1 standard.

Also, your device will be:

- Load tested

- Have required warning markings

How Can Mazzella Help With Your Below-The-Hook Lifting Devices?

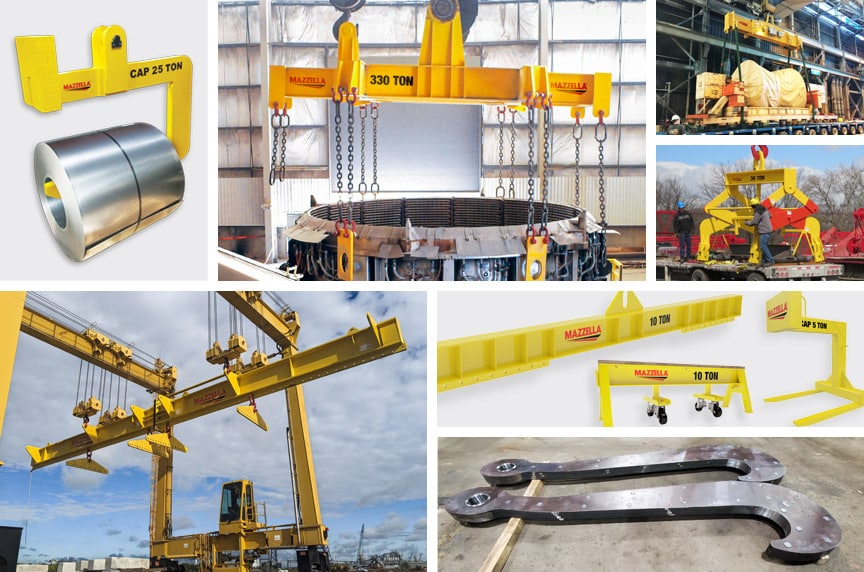

Mazzella has more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes. On-staff engineers and our commitment to ISO 9001: 2015 guide us to continued success in manufacturing quality products and processes.

Mazzella understands the ASME standards for below-the-hook lifting devices, and has an engineer who sits on the ASME B30.20 sub-committee. Also, we have the appropriate insurance coverage to provide you with a device that is certified and backed by the standards. Mazzella lifting devices will meet every OSHA requirement and ASME standard.

We can design and fabricate all types of below-the-hook lifting solutions for any application—all of our work is done in compliance with ASME B30.20 Below-the-Hook Lifting Devices and ASME BTH-1 Design of Below-the-Hook Lifting Devices standards. Our products range from a common lift beam to an engineered special 150 lb. engine line lifter, and 330-ton electric furnace lifter.

Along with design and fabrication, we provide repair or recertification of engineered below-the-hook lifting devices.

Click here if you need a repair or recertification of your lifting device.

Call us at 800.362.4601 or click here to specify your next below-the-hook project!

Below-the-Hook Lifting Devices

We have more than 65 years of experience in designing and developing custom engineered products, below-the-hook lifting devices, and lifting attachments for use with all types of cranes.

On-staff engineering and our commitment to ISO 9001: 2015 guides us to continued success in quality products and processes.

We can design and fabricate all types of below-the-hook lifting solutions for any application—all of our work is done in compliance with ASME B30.20 and ASME BTH-1 standards. Our products range from a common lift beam, to an engineered special 150 lb. engine line lifter, to a 330-ton electric furnace lifter.

Copyright 2022. Mazzella Companies.