How to Properly Install U-Bolt Wire Rope Clips

A step-by-step guide to maximize your wire rope’s strength and prevent accidents and injuries.

Did you know that an improper wire rope clip installation can reduce your rope’s working load limit by up to 40%? But with a properly installed wire rope clip, you can achieve between 80-90% efficiency of the rope breaking strength, depending on the diameter of the wire rope.

Wire rope clips are a common rigging tool used to connect two cable ends together to form the eye of a wire rope or cable assembly. When used and installed correctly, wire rope clips spread the force over a larger area on the live end of the wire rope, maximizing your rope’s strength. They are seen as an alternative to permanent wire rope sleeves—making it easy for riggers to install or remove them.

While clips are common, many riggers do not install them properly, opening the door for the rope to fail and cause damage or injuries to workers. Not torquing them properly and installing them the wrong way are the most common problems we see.

With the help from Mazzella’s in-house rigging experts, this article will offer a step-by-step guide on how to properly install U-bolt wire rope clips. We will also go over relevant terminology, different clip configurations, and best practices to keep in mind.

What are the Different Types of Wire Rope Clips?

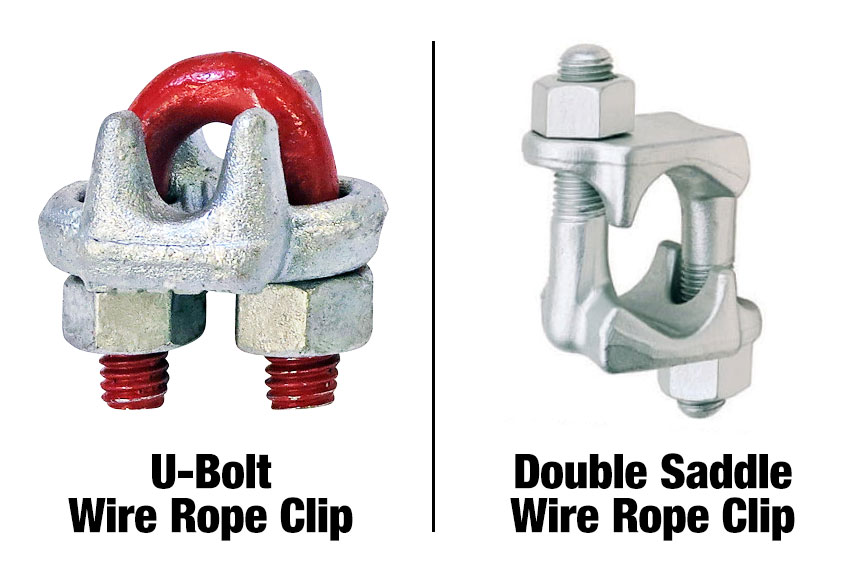

There are two basic wire rope clip designs: U-bolts and double saddles.

U-bolts, sometimes called “Crosbys” by the end user, are the most common clip orientation in the field. Double saddle wire rope clips, also called “Fist grip clips,” have two saddles, one on top and one on the bottom. While both have equal efficiency ratings, each wire rope clip model has slightly different installation steps.

This article will only focus on steps for U-bolt clips, as double saddle clips are considered “dummy proof” and easier to install, as the double saddle design removes doubt on the proper orientation of the wire rope clip during installation. Most issues in the field involving improper wire rope clip usage stem from U-bolt clips.

What Is the Difference Between Forged Wire Rope Clips and Malleable Wire Rope Clips?

As their name implies, forged wire rope clips were designed for more critical applications, with heavy duty projects in mind, like overhead lifting. Forged clips have a thicker profile and can carry much more weight than malleable clips. This makes them great for use on guy lines, towing lines, scaffolding, support lines, and other applications.

On the other hand, malleable clips are made from thinner material, and they are mostly used for making eye termination assemblies with right regular lay wire rope. Malleable clips are commonly used for light-duty, non-critical applications, like guard rails, fencing, and handrails.

How To Install U-Bolt Wire Rope Clips

1. Never Saddle a Dead Horse

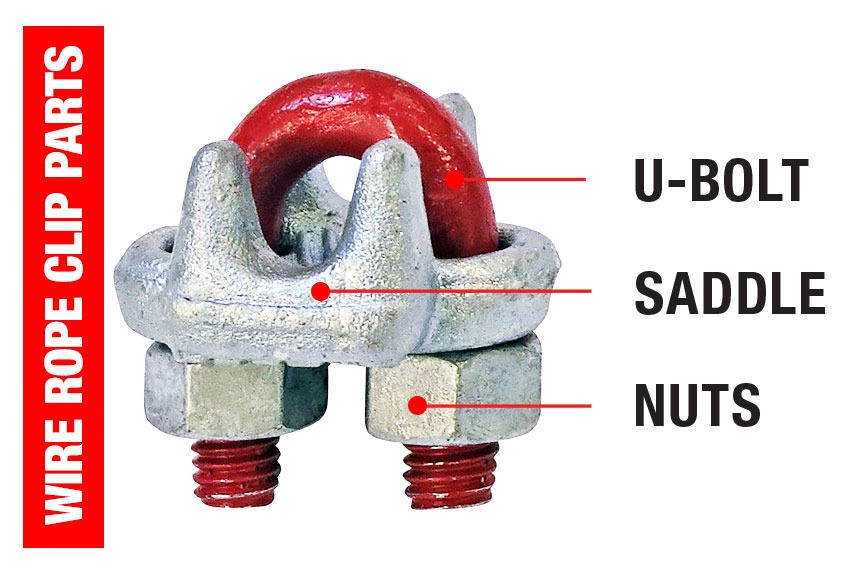

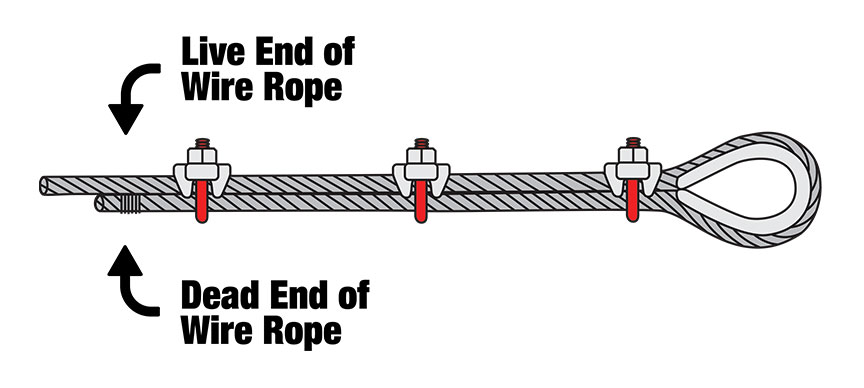

It’s one of the most popular lifting and rigging terms for a reason, as it’s an easy and memorable term to remember for proper clip orientation and installation. You should never apply the saddle of a U-bolt clip to the dead end of a rope. Instead, the wire rope clip’s saddles should always face the live end of the rope.

The saddle end of the clip holds the wire in its form, maintaining the weight capacity. The other side will kink the rope and decrease the rope’s lifting capacity. You should also never stagger your wire rope clips.

2. Properly Turn Back the Rope from the Thimble

Wrap the wire rope around the thimble to form the eye of the rope. Follow the manufacturer’s instructions to figure out the correct amount of rope needed. The first U-bolt clip you install should be one saddle width away from the dead-end part of the rope.

3. Installing Second U-Bolt Clip

The second U-Bolt clip you install should be as close to the loop or thimble as possible.

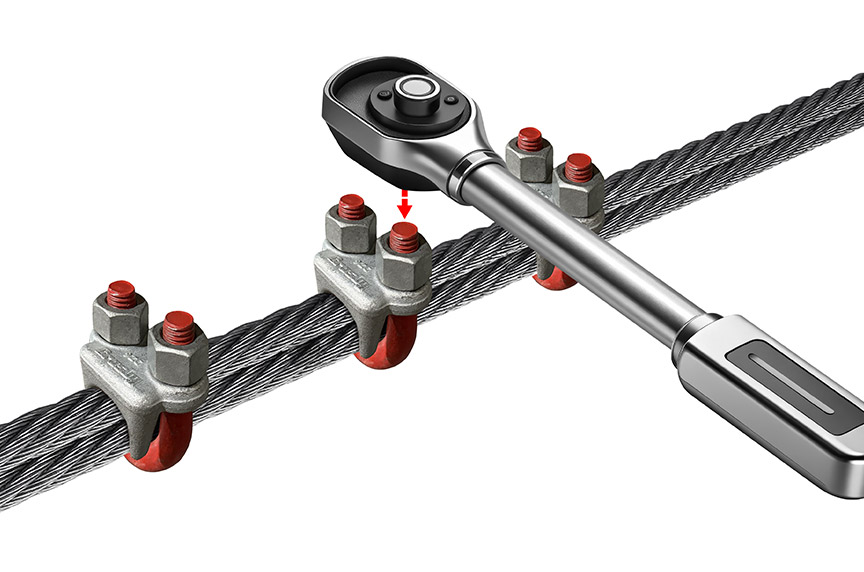

4. Use a Torque Wrench

After installing the second clip, use a torque wrench to tighten the nuts evenly until you reach the recommended torque—you must torque to manufacturers’ specified guidelines.

5. What If More Than Two Clips are Required?

If three (or more) U-Bolt clips are required, space additional clips equally between the first two clips. Tighten the nuts evenly using the torque wrench to the manufacturer’s recommendation.

6. Test Your First Load

Once your U-Bolt clips are installed, you should test the load. This load should be of equal or greater weight than loads expected in use. After the test load, check and use a torque wrench to re-tighten the nuts to the recommended level, as stated by the manufacturer.

Other Important Tips to Consider When Installing Wire Rope Clips

Always Refer to Manufacturer’s Specifications

When in doubt, refer to the manufacturer’s specifications to ensure proper installation and torque settings. While practices like never saddling a dead horse are universal, each company will have certain recommendations on torquing and the amount of rope needed for a turnback.

Periodically Inspect Your Wire Rope and Clips

Inspecting your rigging equipment is essential to creating safe working environments. All rigging equipment should have a visual inspection before use, looking for cracks, gouges, kinks, or any abnormalities.

Your company should also designate a Competent Person to perform a daily, or pre-shift, hands-on inspection of hardware, slings, and all fastenings and attachments for damage, defects, or deformities. For additional guidelines on proper use, care, and inspection of wire rope clips, refer to ASME B30.26 Rigging Hardware.

Pully / Sheave

Use an extra wire rope clip if a pulley / sheave is used for turning back the wire rope instead of a thimble.

Do Not Over-Tighten the Nuts on Your U-Bolts

Over-tightening the nuts can cause a kink in the rope, which would weaken the rope and cause it to be removed from service.

What are Some Common Mistakes When Installing Wire Rope Clips?

While simple tools, it’s common to see wire rope clips not installed properly in the field. Some of the most common mistakes people make include:

Saddling a Dead Horse

One of the most common mistakes regarding wire rope clips is saddling the dead horse, where riggers place the clip saddle on the dead end if the wire rope.

Using the Wrong Wire Rope Clip Model

Pay attention to your application to determine the correct clip model to use. As mentioned earlier, forged wire rope clips are meant for heavy duty applications, such as overhead lifting. Malleable clips will be great for making eye termination assemblies only and light duty applications, such as residential fencing or other low risk applications.

Using the Wrong Number of Wire Rope Clips

The number of wire rope clips needed will depend on the size of the wire rope. Refer to the manufacturer’s specifications to learn more.

Not Torquing to the Manufacturer’s Recommendations

Not torquing the clips to the required torque rating can reduce the wire rope’s working load limit by a considerable amount—40% in some cases. To determine if you have torqued them properly, follow the manufacturer’s specifications. Torquing above the manufacturer’s specifications could damage the rope.

How Else Can You Improve Your Lifting and Rigging Processes?

Wire rope clips are one of the many tools riggers can use to improve their safety and overall rigging processes. However, simple tools, it’s important to follow instructions on proper installment to avoid failed loads and potential injuries for workers. Before conducting a lift, take a few minutes to check if your clips are installed correctly. It will be worth it.

We hoped this article helped you better understand:

- Steps for installing U-bolt and wire rope clips

- Common mistakes people make when installing wire rope clips

- The difference between forged and malleable clips

- The importance of properly torquing your clips

You should also take the time to periodically inspect your wire ropes and wire rope clips, along with other rigging equipment at your job site. We also understand keeping up with rigging inspection cadences can be difficult, which is why reaching out to a third-party can help take that burden off your shoulders.

Mazzella is a leader in third-party rigging inspections, employing an in-house team with several decades of industry experience that can perform on-site inspections for companies of all sizes and industries. Contact one of our Rigging Specialists to schedule a third-party inspection.

On top of inspections, Mazzella is also a leader in lifting and rigging training. Schedule an online, in-person, or jobsite training session.

You can also purchase U-Bolt wire rope clips on our e-commerce site.

Copyright 2025. Mazzella Companies.