Description

General guide to boom pendant inspection:

- Measure the diameter of the rope at several points along the pendant, especially near the end fittings. Measurements below the rope’s nominal diameter may mean that the core is deteriorating, even if the outside wires and strands appear to be in good condition.

- Inspect the outside wires and strands for damaging rust or abrasive wear caused by loss of lubrication, or by the rope’s contact with the boom or other structures on the crane.

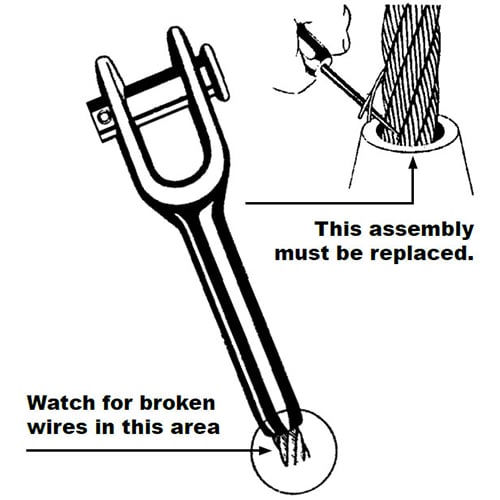

- Inspect the rope for broken wires—especially near the end fittings. Even one broken wire near an end fitting may be a sign that the rope is deteriorating and may be near failure. Any “valley breaks,” that is, wires that have broken in the valley between two strands may also be a sign that there is serious vibration fatigue in the core.

- Inspect the fitting attachments.

Hand spliced: look for slippage in the splice or any tucks that may have pulled out.

Poured zinc or thermo-set resin sockets: look at the base of the sockets for any signs that the wires may be pulling out of the zinc or thermo-set resin. Look at the top of the cone for any sign that the zinc or thermo-set resin is cracked or is chipping or flaking off.

Returned loop swaged: look for any sign that the sleeve may be cracked, crushed or peeling back. Look for any sign that the rope may be pulling out of sleeve.

Flemish eye swaged: look for any sign that the sleeve may be cracked, crushed or peeling back.

Swaged sockets: look for any signs of a cracked or bent shank. Look for any sign that the rope may be pulling out of the socket. - Inspect the end fittings: inspect the fittings for any signs of cracking or distortion. Pay particular attention to the area around the pin holes and along the ears of open sockets.

Inspect the pin holes for any signs of elongation or excessive wear.

Inspect the socket pins for any signs of bending or excessive wear.

Note: If any of the above conditions exists, the pendant should be removed from service and inspected or tested further.

This is intended to be a general guide only. Contact the manufacturer of the equipment, the pendants and/or the end fittings to get specific retirement criteria.

Reference to ASME Standard B30.9.