Proprietary Parts vs Commercially Available Parts: What to Know Before Buying an Overhead Crane

We cover this topic on our podcast, Safety Factor. Click below to watch the full episode.

When you’re investing in a new overhead crane, there’s one critical decision that often gets overlooked—whether to choose a crane built with proprietary parts (available only through the OEM) or one designed with commercially available components. This decision can affect the crane’s serviceability, the cost and speed of future repairs, and even your ability to work with independent service providers.

The process of ordering an overhead crane can be a long and convoluted process, especially if you have never done it before. And according to our experts, not prioritizing commercially available replacement or repair parts for your new system can be a disaster for your organization.

In this article, we will walk through the differences between proprietary and commercially available parts, the pros and cons of each, and what you need to consider before making your next crane purchase.

Here is what we will cover:

- What Are Proprietary Overhead Crane Parts?

- What Are Commercially Available Overhead Crane Parts?

- How Do Commercial Crane Parts Reduce Downtime and Costs?

- Pros and Cons: Proprietary vs. Commercial Crane Parts

- Why Do Some OEMs Push Proprietary Crane Designs?

- What’s the Real Cost of Overhead Crane Downtime?

- What’s the Total Cost of Overhead Crane Ownership?

- How Can You Evaluate Crane and Hoist Component Flexibility?

- Top Questions to Ask Before You Buy An Overhead Crane

- Final Advice

What Are Proprietary Overhead Crane Parts?

Proprietary parts are components designed and manufactured by the original equipment manufacturer (OEM) and are exclusive to that brand of crane. These parts are typically not available through third-party distributors and must be purchased directly from the OEM or an OEM distributor.

Examples of proprietary parts include:

- Custom hoists

- Unique motor drives

- Specialized control systems

- OEM-only gearboxes or brakes

Only the OEM—or their authorized service provider—can source or install these parts, which can limit your flexibility and impact your long-term maintenance strategy

What Are Commercially Available Overhead Crane Parts?

Commercial parts, also referred to as off-the-shelf or standard components, are sourced from common industrial manufacturers and are used across multiple crane brands. These might include:

– Motors

– Gearboxes

– Variable frequency drives (VFDs)

– Control pendants and push-button stations

Because these parts are widely available, they can be purchased and installed by most qualified crane service providers, including independent companies.

How Do Commercial Crane Parts Reduce Downtime and Costs?

You might not think about parts sourcing when you’re in the design and purchasing phase, but it’s one of the most important long-term considerations. According to our overhead crane specialists, the choice between proprietary and commercial parts affects:

- Maintenance turnaround time

- Repair costs

- Downtime and productivity

- Long-term total cost of ownership

- Vendor flexibility and control

Pros and Cons: Proprietary vs. Commercial Crane Parts

| Factors | Proprietary Parts | Commercially Available Parts |

| Availability | Limited to OEM | Readily available from multiple suppliers |

| Lead Times | Often longer, especially if parts are made-to-order | Typically shorter due to off-the-shelf access |

| Serviceability | Must use OEM or authorized techs | Can be serviced by most qualified providers, |

| Cost | Often higher due to exclusivity | Usually lower due to competition |

| Long-Term Flexibility | Low: you’re tied to one vendor | High: allows for open-market support |

| Innovation/Performance | Sometimes highly engineered or integrated | Can vary based on brand, but often high quality |

| Risk of Obsolescence | Higher: OEM may discontinue parts | Lower: multiple sources and suppliers |

Why Do Some OEMs Push Proprietary Crane Designs?

In our recent podcast conversation with crane service professionals, one reason became clear: OEMs often design cranes with proprietary parts to secure long-term service contracts. By locking customers into their ecosystem, they ensure recurring revenue on maintenance, repairs, and replacement parts.

When a customer has to go through one specific source for every part or service call, they don’t have a choice. It’s a great business model for the manufacturer.

However, that model doesn’t always benefit the end-user. If your crane breaks down and you need a proprietary hoist motor with a 10-week lead time, your operation could grind to a halt, costing you time, money, and possibly even customers.

Retrofitting commercially available components to existing cranes with proprietary components is not an easy task. So, thinking you can deal with the parts and repairs later is not a good strategy.

What’s the Real Cost of Overhead Crane Downtime?

Consider the cost of an unexpected breakdown:

- Emergency service call: $2,000+

- Downtime labor cost per day: $5,000–$20,000 depending on industry

- Expedited OEM part shipment: Often 2x or 3x standard cost

And none of that accounts for the ripple effects: missed deadlines, lost revenue, or damaged reputation. With commercial components, you can often source a replacement the same-day or next-day, dramatically reducing your time to repair. In industries like automotive, steel production, or warehousing, every hour of lost uptime impacts your supply chain and customer satisfaction.

A single hour of unplanned production downtime due to a failed overhead crane can cost manufacturers anywhere from $10,000 to over $250,000, depending on the size of the operation and the industry.

In sectors like automotive or steel, that figure can easily exceed $1 million per hour. According to a 2023 Siemens report cited by Peoplegeist, the average cost of downtime in the automotive industry has surged to more than $2 million per hour, while the general manufacturing average is around $260,000 per hour. These numbers highlight why proactive maintenance and rapid response to equipment failures are so critical for modern production facilities.

What’s the Total Cost of Overhead Crane Ownership?

It’s easy to only focus on the purchase price when evaluating new cranes. But that’s only part of the equation. The real cost of ownership includes:

- Service and repair expenses

- Downtime losses

- Availability of parts over time

- Ability to competitively source components

Choosing commercial components helps mitigate the risk of overpaying for basic service and gives you the flexibility to shop around. It also enables your internal maintenance teams to troubleshoot and repair systems without waiting on the OEM to respond or dispatch their technician.

When Proprietary Parts Hurt

Let’s say you have 15-ton overhead crane built with proprietary controls, and you need a simple limit switch replaced. Unfortunately, that switch was only available from the OEM and has a lead time of a week. No compatible substitute exist. Your overhead crane sits idle for over a week. Production was delayed, customer orders were missed, and the company incurred over $50,000 in lost time and emergency shipping.

Had that crane been built with commercially available parts, the switch could have been replaced in 24 hours by a local technician, saving time and thousands of dollars.

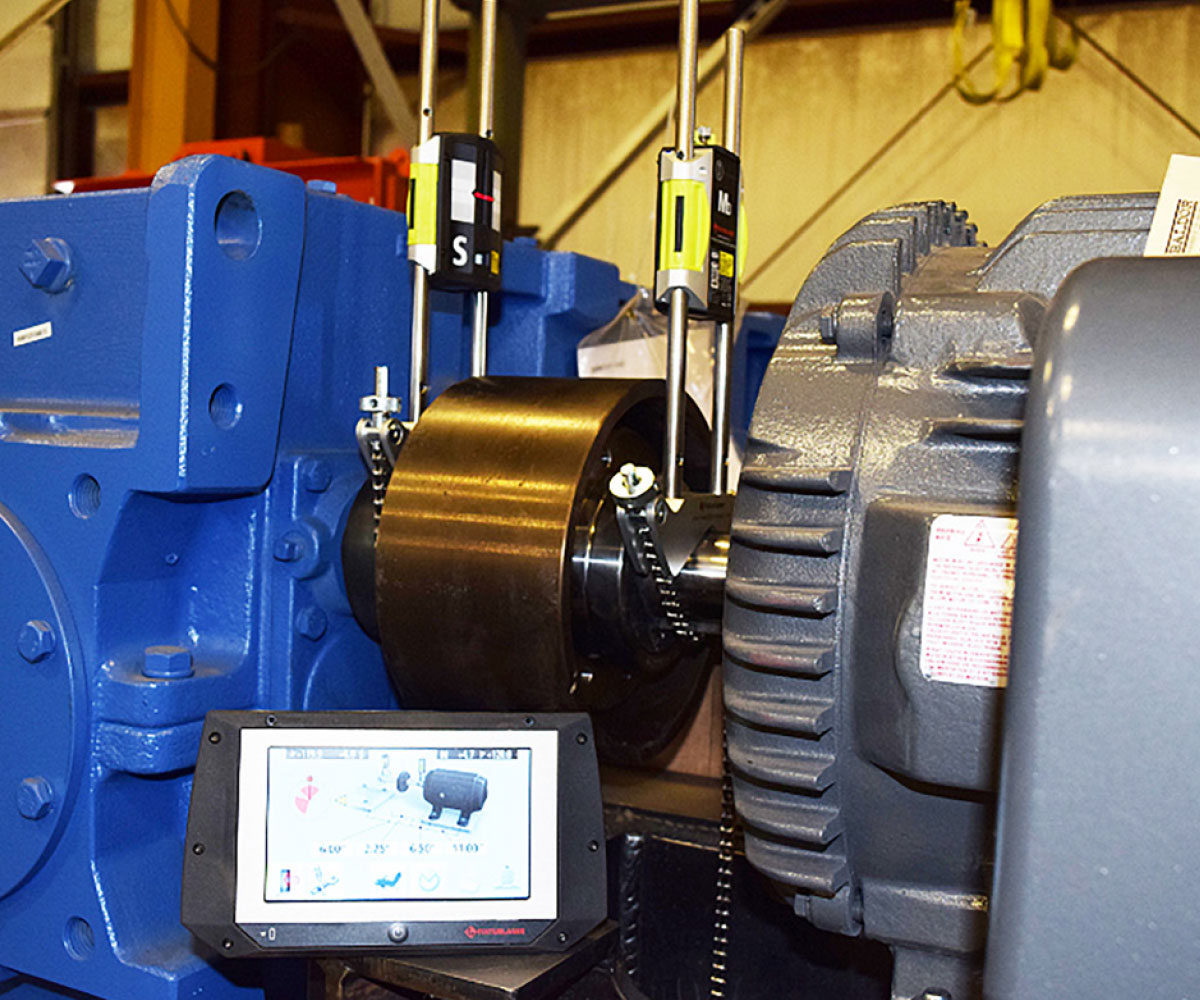

How Can You Evaluate Crane and Hoist Component Flexibility?

When reviewing a crane design or proposal, it’s essential to dig into the bill of materials. Ask the supplier:

- What brands are used for motors, drives, and hoists?

- Are these parts commonly stocked by local distributors?

- Can my in-house team access manuals and specs?

- Are third-party technicians certified to work on this equipment?

- Are detailed drawings provided for machined and manufactured parts so they can be sourced locally?

A reputable crane manufacturer should be transparent about their component choices and willing to design a system that supports your long-term needs.

Top Questions to Ask Before You Buy An Overhead Crane

To avoid getting locked into a restrictive service model, ask these questions before signing off on a new crane purchase:

- Are the major components proprietary or commercial?

- Can I choose the brands of motors, drives, and controls used in the design?

- What is the lead time for replacement parts?

- Can my preferred service provider perform maintenance and repairs?

- Will I have access to component documentation, detailed drawings, and part numbers?

If a manufacturer resists providing clear answers to these questions, it may be a red flag. You should also ask for blueprint drawings and designs ahead of time.

Final Advice on Choosing Between Proprietary and Commercial Crane Parts

When buying a new crane, don’t just focus on the specs, features, or even the price. Ask what’s inside and who controls it.

Choosing a crane built with commercially available parts gives you greater control, lowers long-term costs, and ensures you’re not at the mercy of a single vendor. While proprietary systems may offer advantages in certain custom or integrated applications, they often come with hidden costs that only show up when something goes wrong.

It is also recommended to keep critical spare parts on hand in all circumstances, but commercially available parts allow a lot more control and flexibility in acquiring and replacing those parts.

If you’re unsure about what’s best for your operation, talk to a crane service expert who understands the long-term implications of your purchase decision. At Mazzella, we want you to come back to us because you want to, not because you have to.

Whether you’re replacing an old unit or designing a new system from scratch, Mazzella’s team of overhead crane experts can help you make informed decisions that support your operation today and in the future. Contact us to learn more about our crane design, installation, and inspection services.

Copyright 2025. Mazzella Companies.