7 Things You Should Know Before Buying a Below-the-Hook Lifting Device

If you’re thinking about buying a below-the-hook lifting device, then you’ve probably realized there’s an inefficiency or a possible safety issue with the way you’re currently lifting materials.

“Below-the-hook lifting device” is a general term that can include a variety of engineered lifting beams, spreader beams, c-hooks, lifting tongs, vacuum lifters, or magnet lifters. These custom lifters offer more load control and support than traditional rigging. When used in conjunction with a crane and rigging equipment, a below-the-hook lifter can eliminate the hazard of a load tipping, sliding, or becoming unbalanced—as well as reduce low sling angles and the tendency of slings to crush or bend a load.

In this article, we’ll walk you through seven different things you should know before buying a below-the-hook lifting device. If you’ve never gone through the consultation, quotation, and approval process, you’ll learn more about:

- How you can customize your below-the-hook device for your specific application and operating environment

- What information engineers and project managers need to know before they can provide a quote

- How you can help to make the design and approval processes go smoothly

- How ASME BTH-1 design parameters and basic physics may influence the design and specifications of your lifting device

- Why the approval process is so important to the success of the project

Podcast: What You Should Know Before Buying a Custom Lifting Device

Mazzella Companies | The Rigging Professor

1. Most Below-the-Hook Lifting Devices Are Custom Products

Some products just can’t be bought off of the shelf or picked out of a catalog. Below-the-hook lifters tend to fall into this category. Our Engineering department prides itself on designing and fabricating “Serial Number 001” lifters—meaning a totally customized lifting device that’s never been designed or made by our team before.

The advantage of this is that the device is custom-designed for your specific lifting application. Special consideration is given to the environment it will be used in, the type of load it will be lifting, and how often it will be used.

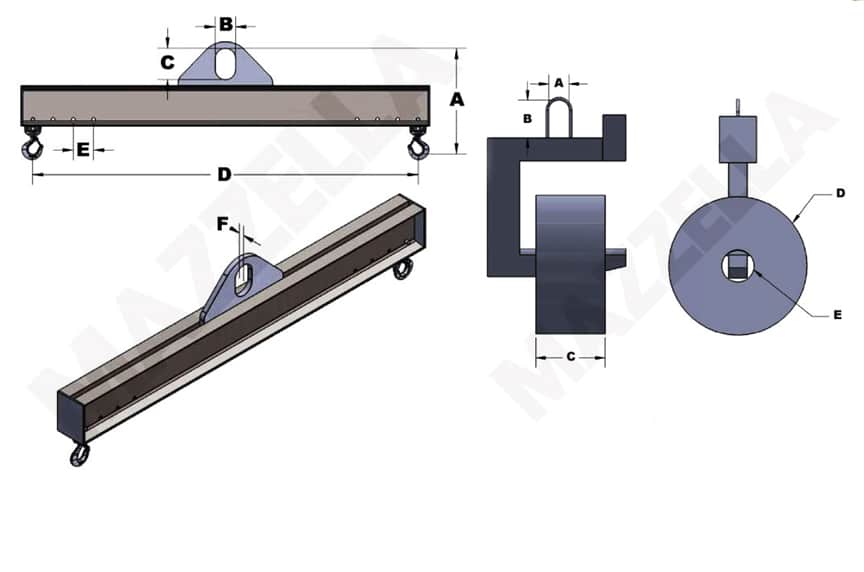

Some lifting devices, like spreader beams or lifting beams, can be more standardized in their design and there may be an off-the-shelf solution available. However, we often see different factors that can take a standard lifting device and turn it into a custom device, including changes to:

- Rated capacity

- Fixed or adjustable spread

- Number and location of bail(s)

- Number and location of lifting lugs

- Length and height requirements

- Low headroom or obstruction considerations

Understand that when you buy a below-the-hook lifter—whether it’s a lifting beam, c-hook, tongs, or something else—you’re most likely going to end up with a customized solution. If you plan to go with the cheapest option and “try to make something work” from a catalog, you may end up with a product that’s under-specified or not designed for your unique environment or lifting application.

2. Gather Preliminary Information and Specifications Before Your First Consultation

When you put some thought into the design and specifications of your lifter upfront, you’ll be able to provide more information during the initial consultation, which will result in a more accurate quote from the manufacturer.

But don’t worry, you don’t need to have an exact idea of what you need! These specifications are mainly considerations and talking points to use during your initial consultation with a salesperson.

This information helps a team of estimators and engineers get some numbers to begin running initial calculations, determine material needs, and start designing a rough concept for your lifting application.

General Product Category

What type of below-the-hook lifting device are you considering? Help the manufacturer understand what exactly the device will be lifting. This will help them hone in on the right type of solution, including:

- Lifting beams

- Spreader beams

- C-hooks and coil lifters

- Pallet lifters and load lifters

- Lifting tongs and grabs

- Die horses / die buffers

- Other / custom solutions

Quantity

If this lifting device will be used in a production process, are there multiple workstations throughout your facility where you can utilize more than one? Do you have multiple facilities or locations that could benefit from this type of device?

Capacity

What is the weight of the load that you’ll be lifting? Below-the-hook lifting devices can be designed to assist with lifting loads as light as 50 lbs. and all the way up to 350 tons or higher! Make sure that you have an understanding of the capacity requirements for your lifting device.

Does the Lifter Need to be Adjustable?

Lifting beams and spreader beams can be designed to be adjustable with variable bail positions and lifting lug positions. They can also be telescopic in design to meet minimum and maximum length requirements.

Lifting tongs can also be designed to accommodate a wide range of product diameters.

By providing the manufacturer with the minimum and maximum sizes of loads you’ll be lifting, they can try to design one solution that can be adjusted to accommodate a variety of load or product sizes.

Hook Size

What is the size of the crane hook that this lifting device will be attaching to? If the engineers know the size of the hook, they can design the bail to be the correct size to accommodate the crane hook. If the hook is large, you may need an over-sized eye or pin in the bail.

If you don’t know the exact size of the hook, it can often be reverse-engineered by providing the manufacturer with the capacity of the hoist, overhead crane, or mobile crane that the lifting device will be attached to.

By the time you get to the approval process, you will want to know the exact size of the crane hook and make sure the proposed bail size in the approval drawings can accommodate it.

Budget

Being upfront about your budget will help the manufacturer understand any limitations they may have in regards to material, design, or engineering to complete the project. The manufacturer can let you know pretty quickly if your expectations for the product are realistically in-line with the budget you have available.

From there, you can work together to design and build the best solution within or below your expected project spend.

Delivery Date

Be honest with your timeline and it will help the manufacturer get you the best price. The manufacturer may have in-house fabrication capabilities, may outsource fabrication, or may do a little bit of both depending on the project requirements.

When you need a lifting device—and need it now—the manufacturer usually has to push in-house production that was already scheduled, may need to book last-minute time on machinery outside of their facility, and may need to pay overtime to their employees to get the job done on time.

Not to mention, any rush charges incurred from the manufacturer’s material suppliers, service providers, and freight/shipping resources will be passed onto the customer.

When the manufacturer has a hard delivery date, they can be more efficient with the ordering of materials and scheduling of their resources—and ultimately those savings can be passed on to the end-user.

3. Environmental and Application-Specific Considerations Are Just as Important as the Product Specifications

Make sure that the manufacturer is aware of any limitations or outside factors that may influence the design of the lifting device. Below are some application-specific and environmental considerations that a manufacturer will want to know about:

What is the Below-the-Hook Lifting Device Handling?

It may seem like you would have covered this already, but you’ll want to go into as much detail as possible about the type of load or material that is being lifted.

For example, you may want to use lifting tongs to lift metal tubes that have a highly-polished finish and you can’t afford for them to get scuffed or marred. The manufacturer would need to add in additional protection so that there isn’t steel-on-steel contact which could scratch or damage the product.

Or, you may be lifting batteries or some other type of product with electrical properties. Many companies will use lifters made from wood or fiberglass since these are non-conductive materials. Any type of hardware used in conjunction with those lifters may need to be bronze-coated—which can be rather expensive.

How Are You Currently Lifting the Load?

What type of device is lifting the load? Is it a stationary hoist? An overhead crane? A mobile crane? A forklift? What type of rigging—including the types of slings and hardware—is being used?

What is the capacity of these items and what percent are you currently lifting at capacity? A load that is already approaching capacity, may exceed the rated capacity of the lifting equipment when the weight of a below-the-hook lifting device is added and accounted for.

What Type of Environment Will the Lifting Device Be Used in?

A lifting device that is used in a traditional manufacturing facility could be very different than a comparable device used in a steel processing facility. Special consideration has to be given to the following environmental factors:

- High heat environments (steel mills, steel processing facilities, paper mills, etc.)

- Chemically-active environments (steel pickling, galvanizing, etc.)

- Outdoor environments (construction sites, marinas, rail yards, etc.)

Exposure to heat, chemicals, or moisture may require special grades of steel or aluminum. The manufacturer may want to use an epoxy paint or add a powder coat finish to further protect the lifter from degradation and corrosion.

What Type of Obstructions or Obstacles Will the Lifter Encounter?

Is this a low-headroom application? A lifting beam may need to be designed with a special bail to account for lift height or low headroom considerations.

Is there a pit or a hole in the floor that a load will be raised up from or lowered down into? If so, what are the dimensions of that opening? If the engineers are aware of this, they’ll know that there are limitations to how long or how wide they can design a custom lifting device. What type of machinery will be operating near this device? Are there workers, machines, or racking systems nearby that this lifter will need to clear when moving a load up and down a bay?

When the manufacturer is aware of all of this information, there won’t be any surprises when it comes to signing off on the approval drawings. There will naturally be some back and forth between the customer and manufacturer in revising or tweaking the design of a lifter. But, multiple rounds of revisions can add significant costs and delay the production and delivery timeline—both of which can be avoided if you provide as much information to the manufacturer during the consultation / quotation process.

4. If Possible, Provide Engineering Drawings, Sketches, 3D Models, or Product Samples

If you can provide the engineers with a sketch with approximate dimensions or an engineering drawing of the product or load, they can quickly get to work on quoting and designing an application-specific solution for you.

Better yet, if you provide the manufacturer with 3D model files, they can load those into the engineering programs they use and “test fit” the support and alignment of your product against a 3D model of their proposed lifting device.

You can even go one step further and provide the manufacturer with an actual sample of the product or load that needs to be lifted. The manufacturer can prototype a solution and test it out on the actual product sample in their facility before they ship it out to you.

You should be aware that tweaks or modifications to the end product are sometimes a natural part of the process. But, if you provide the engineers with a 3D model or product sample you may eliminate those late-stage modifications so your custom lifter is ready to be used as soon as you receive it!

5. Understand How ASME BTH-1 Can Affect the Design of Your Lifting Device

Careful consideration must be given to the service life of a below-the-hook lifting device. That’s why ASME BTH-1 – Design of Below-the-Hook Lifting Devices exists. This standard created by the American Society of Mechanical Engineers (ASME) provides guidance on the minimum structural and mechanical design and electrical component selection criteria when designing a below-the-hook lifter.

When ASME BTH-1 was introduced in March of 2006, two major additions were added for:

- Design Category (static strength criteria)

- Service Life (fatigue life criteria)

Design Category

ASME BTH-1 specifies that there are two different options that you could have—either Design Category A or Design Category B. It’s critical to know how the lifter will be used so that the engineers can design the device and components to the appropriate design factor.

- Design Category A – As defined by ASME BTH-1, “Design Category A should be designated when the magnitude and variation of loads applied to the lifter are predictable, and where the loading and environmental conditions are accurately defined or not severe.” Design Category A lifting devices have a nominal design factor of 2:1 and are limited to Service Class 0. Typical applications for these lifters include lifts at slow speeds, a well maintained lifting device, an experienced crane operator, and the control of a lift supervisor.

- Design Category B – As defined by ASME BTH-1, should be designated when the magnitude and variation of loads applied to the lifter are not predictable, and where loading and environmental conditions are severe or not accurately defined. This is the most common design category with most below-the-hook lifting devices falling under Design Category B. These lifters can fall under service class 0-4 and require a nominal design factor of 3:1 to the yield strength of the steel.

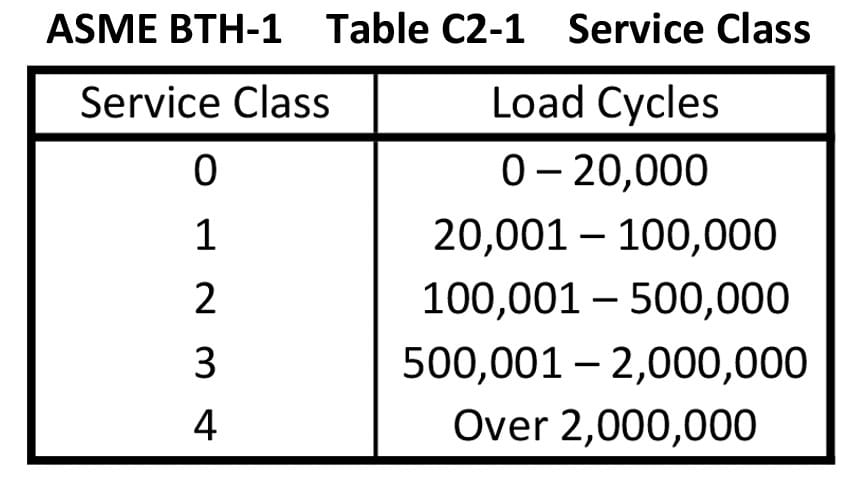

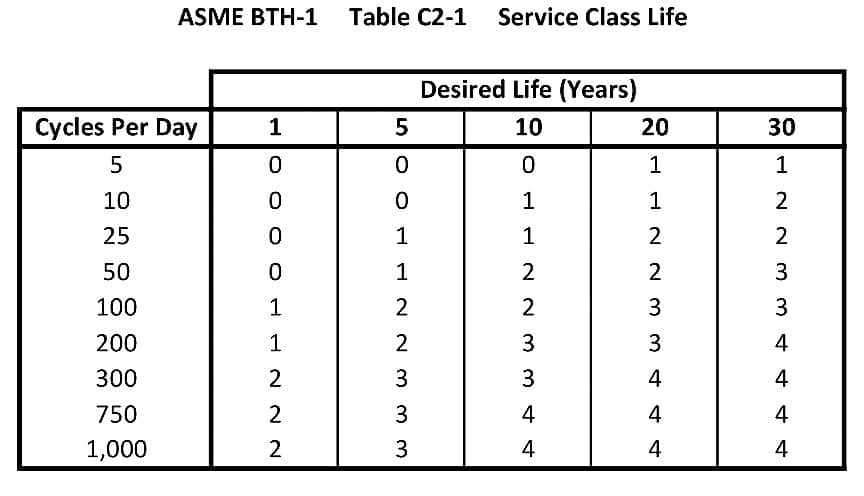

Service Class

The Service Class of a lifter is based on the load cycles that a lifter will see in a 24-hour period. The service class 0-4 designation defines the total life cycles a lifter can see based on the specified fatigue life of the lifter.

You can look at Design Category and Service Class as being similar to the duty cycle of an overhead crane. You’re basically providing the engineers with information on how often the lifting device will be in use and what classification it should fall under. This allows manufacturer to do the following:

- Account for a specific design factor

- Account for the added stresses and rigors of a device operating in extreme environments or high-production facilities

- Design a below-the-hook lifter that’s compliant with ASME and OSHA standards

Let the manufacturer know how many cycles per day, and how many shifts per day, the device will be in use. The manufacturer may want to add gussets to add strength to certain areas of the device. Or, they may want to add bushings to the bail and lifting lugs to reinforce those areas and protect against wear and tear.

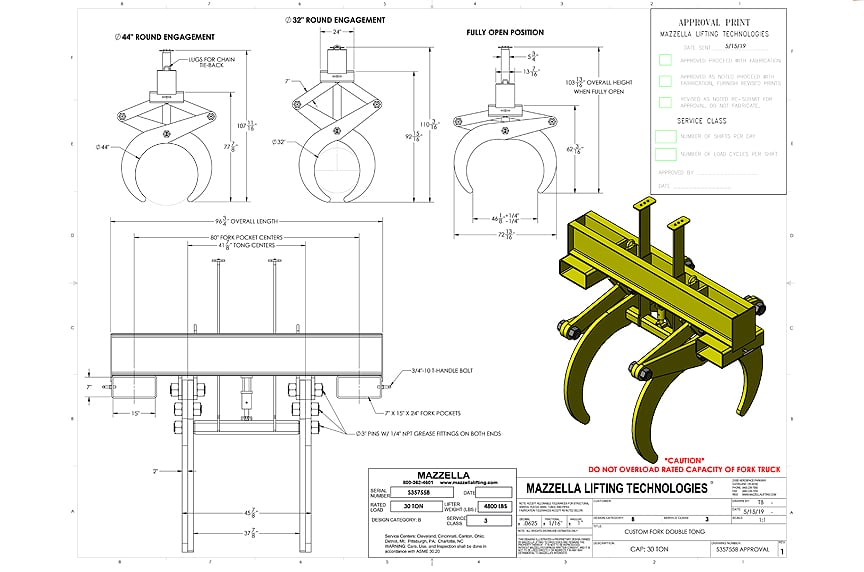

6. The Importance of the Approval Process

The approval process is one of the most important stages of buying a below-the-hook lifting device.

This is the last chance for you and your team to review the dimensions, specifications, and capabilities of your custom lifting device.

Once the drawings are approved by the customer, the manufacturer is off and running. Material is ordered, and production and fabrication schedules are set.

When you receive the approval drawing from the customer, double-check the following information:

- Bail – quantity, size, and location (center-to-center distance)

- Lifting lugs – quantity, size, and location (center-to-center distance)

- Length, width, height measurements and dimensions

- Radiuses (for lifting tongs)

You may want to schedule one final meeting with the manufacturer prior to signing off on the drawings. The manufacturer can walk you through the design and specifications of the proposed solution and answer any final questions you might have.

This can help to eliminate any misunderstandings or miscommunications that could result in added costs or delays to production and delivery.

7. Physics Trumps Everything

Physics will always dictate the design parameters and success of a below-the-hook lifting device. A heavy load requires more steel material to design and reinforce a product that can lift it. If you throw in low headroom, or other obstructions or restrictions, it may not be physically possible to design a lifting device that meets all of your project requirements.

A beam may have to have a specific span to meet the capacity and design factor requirements. You may want that beam to be smaller or lighter, but the engineers are locked into calculations and parameters that determine the design factor and the ability to lift a particular load. You may want an adjustable beam to be thinner or more streamlined, but remember that there needs to be a specific amount of material overlap at the minimum and maximum adjustments to maintain a consistent lifting capacity.

Just remember that the numbers don’t lie. It’s important to trust the engineers and the specifications and design parameters they provide. They’re designing your lifter to withstand the rigors and forces being applied to it by the load, as well as designing to ASME BTH-1 requirements. Their goal is to get you a lifting device that is compliant with industry regulations, will withstand your operating environment, and will remain in service for a long time.

Wrapping it Up

We hope this article helped educate you on how to properly plan for the purchase of a below-the-hook lifter. We know how satisfying it can be to receive a high-quality lifting device that satisfies the needs of your application, and also makes your job more efficient and helps to keep your employees safe.

If you remember the following things, it’ll go a long way towards ensuring a smooth consultation, quotation, and approval process.

Always provide the sales rep or manufacturer with as much information as possible:

- What are you lifting?

- How are you currently lifting it?

- What special environmental considerations should they be aware of?

- How often will this device be in use?

- What is your budget?

- What is your timeline for delivery?

Trust the process. Know that a reputable manufacturer will design a below-the-hook device that will be designed to ASME BTH-1 design standards, will have a 2:1 or 3:1 design factor, and will meet the service life requirements based on estimated usage.

Take the approval process seriously. Make sure you carefully review the approval drawings for accuracy and ask questions if you’re confused about anything. A quick 20-minute conversation can clear up confusion or misunderstandings, and will help to avoid re-designs or delays that may set production back and add additional expenses to the project.

The numbers don’t lie. Understand that there is a reason that the device was specified the way that it was due to the laws of physics as well as industry design parameters. You can always work with the manufacturer to tweak a design or get creative in an alternative solution, but put faith in their designs and recommendations that they’ve worked towards the best solution for your specific application.

At Mazzella, we treat each lifting challenge the same—whether we’re making a common lift beam for a 150 lbs. load, or a specially-engineered 330-ton electric furnace lifter. We have a fully-staffed Engineering department, project managers, and estimators to help solve your lifting challenges and design the perfect solution for your unique lifting application.

We welcome the opportunity to address your overhead material handling needs. If you’re interested in learning more about how a below-the-hook lifting device can improve the efficiency and safety of your overhead lifts, or want to schedule a consultation, contact us to speak with a Lifting Specialist.

Copyright 2019. Mazzella Companies.