A Year in Review: The 10 Best Lifting and Rigging Articles of 2025

We’ve compiled a list of our 10 best articles from 2025.

For lifting and rigging companies, 2025 was a year of highs and lows.

Manufacturers, distributors, and suppliers had to adjust to sweeping tariffs that sent shockwaves through the global economy. The fight to address our industry’s growing labor shortages continues. And companies are trying to keep pace with rapid technological advancements, especially in the automation and AI spheres.

Through it all, our industry continues to meet the demands of a rapidly changing world.

As the year comes to an end, and we begin planning articles for 2026, we’ve compiled a list of our 10 best articles from 2025. This list is by no means a power ranking, but a collection of some of the most popular articles and some of our personal favorites.

Table of contents

- 6 Ways to Preserve Knowledge in the Lifting Industry

- How to Properly Install U-Bolt Wire Rope Clips

- Which Slingmax® Lifting Sling Is Right for You?

- A Dictionary of Fall Protection Terms

- What Is AI’s Role in Warehouse Solutions?

- Suspension Trauma in Fall Protection: What Safety Managers Must Know

- What are the Most Serviced Items on Overhead Cranes?

- SE Hoists, PE Hoists, and CE Hoists: Which Should You Choose?

- A Breakdown of Scope: Reasons to Consider AI-Enhanced Utility Stringing Line Inspections

- How Much Does a Rigging Inspection Cost in 2025? Key Factors to Consider

- Looking Onward to 2026

6 Ways to Preserve Knowledge in the Lifting Industry

In many industries and companies across the country, there’s a concerning trend: millions of workers with decades of experience are about to retire. And no one is there to fill their position or learn from them.

The lifting and rigging industry is not immune to this phenomenon. When talking to industry experts, they routinely express concerns of “lost knowledge” in the industry.

Soon, those experienced men and women who’ve perfected their craft over the years will retire. Who will teach the younger generations about the best way to hand splice wire rope? Who can pass on tips on sewing synthetic lifting slings? Who will pass that “tribal knowledge” to the next generation?

If action isn’t taken, critical industry knowledge and technical expertise will be lost, and our industry, and world, will be worse off.

However, there are many steps your organization can take to prevent this from happening. We cover them in this article.

How to Properly Install U-Bolt Wire Rope Clips

Wire rope clips are a common rigging tool used to connect two cable ends together to form the eye of a wire rope or cable assembly. When used and installed correctly, wire rope clips spread the force over a larger area on the live end of the wire rope, maximizing your rope’s strength. They are seen as an alternative to permanent wire rope sleeves—making it easy for riggers to install or remove them.

With the help from Mazzella’s in-house rigging experts, this article will offer a step-by-step guide on how to properly install U-bolt wire rope clips. We will also go over relevant terminology, different clip configurations, and best practices to keep in mind.

Which Slingmax® Lifting Sling Is Right for You?

Lifting slings can be found in just about every job site or environment: steel mills, mechanical garages, automotive assembly lines, manufacturing plants, construction and excavation sites, mining, and much more. As technology advances in the lifting industry, new lifting slings have been created to meet the unique environments each rigger works in.

Our partners at Slingmax Rigging Solutions understand this and have developed four high-performance synthetic roundsling models: the Twin-Path® sling, the Helix™ Sling, the Single-Path sling, and the Sparkeater® sling. While all of these are backed by engineered data and manufactured with high-quality material, each one was designed with a specific application in mind.

To help your decision-making process, our article will review each Slingmax synthetic lifting sling, reviewing their lifting capacities, unique features, and their ideal work applications.

A Dictionary of Fall Protection Terms

Whether you’re training a new worker, brushing up on safety standards, or reviewing your company’s fall protection program, understanding the language of fall protection is essential.

OSHA, ANSI, and equipment manufacturers all use specific terminology to describe systems, components, and procedures that keep workers safe at height.

A clear understanding of these terms helps ensure compliance, improves communication between crews and safety managers, and reduces the risk of accidents. This dictionary brings together the most common fall protection terms used in OSHA’s 1910 (General Industry) and 1926 (Construction) standards, along with the terms you’ll encounter on job sites and in safety training.

Use this guide as a reference for toolbox talks, training sessions, and daily operations to help your team speak the same language when it comes to working safely at height.

What Is AI’s Role in Warehouse Solutions?

AI-driven tools are already transforming the way warehouses operate. Like all industries today, warehouse operators are no longer wondering if they will use AI. Now, they are trying to figure out how it should be used.

Warehouse solutions experts are already seeing this shift firsthand. Customers are now using AI platforms to do tasks in seconds that would normally take a specialist much longer to complete.

Our Warehouse Solutions experts often get asked, “Are pallet rack customers turning to AI instead of integrators?”

The short answer is no, but AI is definitely changing the conversation. We’re seeing customers adopt AI to improve pallet racking efficiency in ways that were harder to achieve before.

The rise in AI is raising other important questions within industry circles. Will warehouse integrators be replaced by AI? How will companies use AI in their warehouse operations?

Suspension Trauma in Fall Protection: What Safety Managers Must Know

Working at height is one of the most regulated and hazardous areas. According to data from the Occupational Health and Safety Administration (OSHA), falls caused 37% of all construction deaths in 2021. Fall protection equipment is designed to save lives, but it introduces another critical risk that often goes overlooked: suspension trauma.

Suspension trauma can set in under five minutes after a fall and cause life-altering injuries, or even death, to a worker.

For Safety Managers and EHS professionals, understanding suspension trauma, and how to plan for it, is essential for OSHA compliance and for protecting workers in the event of a fall.

In this article, we’re going to cover everything you need to know about suspension, dispel common myths about suspension trauma, and how proper engineered fall protection systems and rescue plan can save your workers.

What are the Most Serviced Items on Overhead Cranes?

Overhead cranes can be one of the biggest long-term investments an organization can make. They can speed up processes, improve employee safety, reduce downtime, and some operations are just not practical to be performed without an overhead crane.

Whether you are a crane service professional or responsible for purchasing cranes for your organization, understanding these common problems and their solutions can help you maintain your equipment and avoid costly downtime. This article will explore the most common issues with overhead cranes and provide practical advice on how to prevent them.

SE Hoists, PE Hoists, and CE Hoists: Which Should You Choose?

Mazzella offers three distinct types of hoists: the SE standard hoist, the PE pre-engineered hoist, and the CE custom-engineered hoist. Each of these hoists is designed to meet specific needs, applications, and industries, ensuring customers can find the perfect solution for their lifting requirements.

But picking the wrong hoist for a job can cause unplanned downtimes, unsafe working conditions, and lost productivity. Mazzella Companies has long been a leader in the field of hoist engineering, providing innovative lifting solutions to a wide range of industries.

To help you make an informed decision, this article will compare the unique features, advantages, price ranges, and limitations of each hoist type.

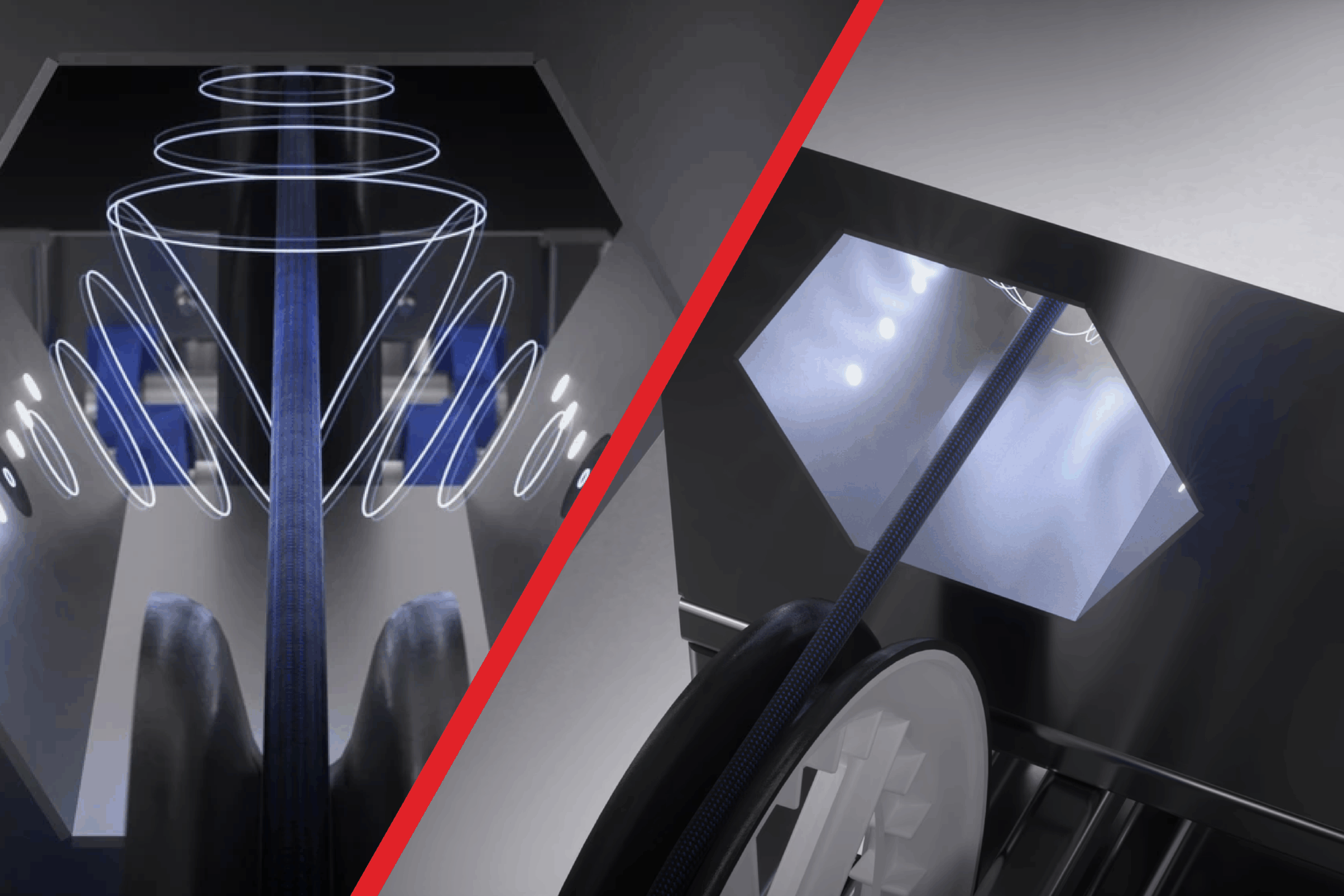

A Breakdown of Scope: Reasons to Consider AI-Enhanced Utility Stringing Line Inspections

We’re always looking to right about emerging trends in the lifting industry. There’s no better example than Scope, an AI-powered inspection platform that captures a 360° view of the line, predicting break-strength and identifying potential hazards.

This occurs in real-time, with software that is continuously learning and improving. Since launching, major utility companies and contractors have used Scope to improve their inspection processes and create better documentation of their fleet’s stringing lines.

We understand that traditional rope inspections can slow down turnaround times, prolong equipment malfunctions, and open the door for inaccurate stories. With increasing demand for stringing line operations, you have no room for these issues to pop up at your job site.

To help, our article looks to break down everything you need to know about the Scope Inspection Platform.

How Much Does a Rigging Inspection Cost in 2025? Key Factors to Consider

Mazzella is committed to being transparent with our customers, and that includes our pricing for products and services.

Every company that uses lifting and rigging equipment knows the stakes are high. If a sling, shackle, or below-the-hook lifting device fails, the results can be catastrophic. Injuries, downtime, OSHA citations, lawsuits, and even loss of life.

That’s why rigging inspections are not optional. They are required by OSHA and ASME standards and are critical to ensuring workplace safety. Still, when safety managers and plant leaders first approach the subject, one of the first questions they ask is: How much does a rigging inspection cost?

At Mazzella, we’ve built one of the most comprehensive rigging inspection programs in the country. This article explains what you can expect to pay, what drives inspection costs up or down, and why investing in proper inspections often saves far more than it costs.

Looking Onward to 2026

We’re thankful for every person who takes the time to read and watch our content.

If you haven’t already, subscribe to Mazzella’s Learning Center so you never miss a new piece of content.

At Mazzella, we take pride in our 70 years of industry expertise. When you have a problem, we have a talented team of in-house Engineers, Lifting Specialists, Inspectors, Trainers, Product Specialists, and Technicians who can help design and develop creative and compliant processes or solutions.

Need help with a big rigging project in 2025? Contact one of our specialists today.

Copyright 2025. Mazzella Companies.