Tower Cranes: Common Terms, Structures, & Systems You Should Know

Do you know the basics of tower cranes? Do you find the terms and information within the OSHA standards overwhelming? No need to worry, as here is an explanation of the basic terms you’ll need to know when working around tower cranes.

“Knowledge is power. Information is liberating. Education is the premise of progress, in every society, in every family.”

Former United Nations Secretary-General Kofi Annan’s words apply to just about every pursuit. Knowledge can be the difference between making it home safely and suffering a catastrophic injury / death. That is especially true when working with tower cranes. Not being educated could do irreparable harm to you, your family and your coworkers.

Educating yourself on the basics of construction cranes, specifically tower cranes, is a great way to jumpstart learning.

In this article, you will learn about:

- Basic terms associated with tower cranes

- Types of tower cranes

- Equipment used for load positioning

- Components and structures for tower cranes

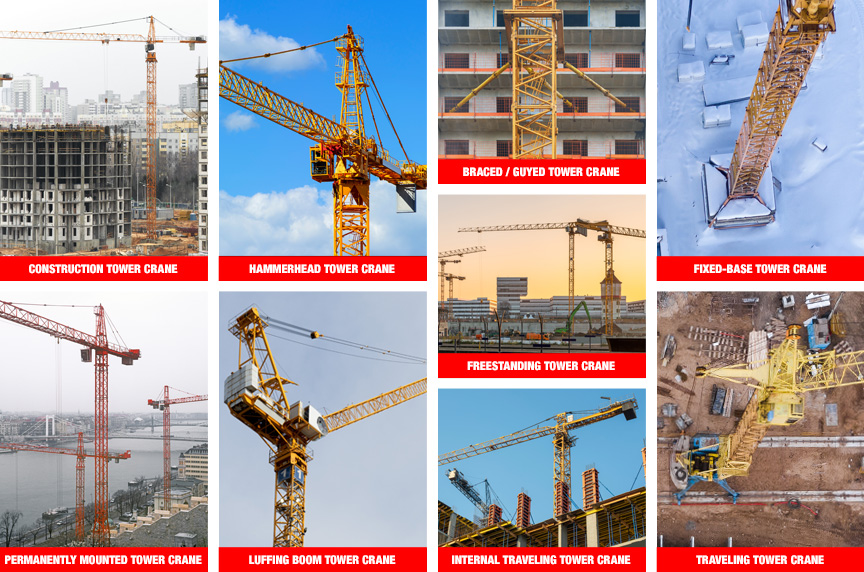

What Are the Different Types of Tower Cranes?

Not all tower cranes are created equally, as they need to be diverse to handle different types of load positioning. As such, there are many types of tower cranes, which will be explained below.

By Type of Application

Just like with mobile cranes, there are different types of tower cranes, including:

- Construction tower cranes

- Permanently mounted tower cranes

The ASME B30.3 Tower Cranes standard defines a construction tower crane as: “a hammerhead, luffing, or other type of tower crane that is regularly assembled and disassembled for use at various sites. It is usually characterized by provisions to facilitate erection and dismantling and may include features to permit climbing or telescoping.”

Permanently mounted tower cranes are defined as: “a hammerhead, luffing, or other type of tower crane that is erected for longer term use at one location (five years or more). The configuration of the crane usually remains unchanged during the entire installation period.”

By Method of Load Positioning

There are two types of cranes used for load positioning, including:

- Hammerhead tower cranes

- Luffing boom tower cranes

A hammerhead tower crane is “a tower crane with a horizontal jib and a load trolley that traverses the jib to change load radius.”

A luffing boom tower crane is: “a crane with a boom pinned to the superstructure at its inner end and containing load hoisting tackle at its outer end, and with a hoist mechanism to raise or lower the boom in a vertical plane to change load radius.”

By Support Arrangement

Under support arrangement, there are three types of tower cranes, including:

- Braced or guyed tower cranes

- Freestanding tower cranes

- Internal climbing tower cranes

A braced or guyed tower crane is defined as “a tower crane with tie-ins or guys attached to the tower to permit the crane to be erected or climbed to greater than the maximum free-standing height.”

A freestanding tower crane is defined as “a tower crane that is supported on a foundation or structural support without assistance from braces, guys, or other means.”

Internal climbing tower cranes are defined as “tower cranes arranged to raise itself from floor to floor in a building as construction advances.”

By Ability to Travel

Additionally, tower cranes are defined by their ability to travel, including:

- Fixed-base tower cranes

- Traveling tower cranes

Fixed-base tower cranes are “freestanding, braced, guyed, or ballasted platform tower cranes that are mounted on a foundation or structural support and do not travel.”

Traveling tower cranes are defined as “freestanding tower cranes mounted on a ballasted platform furnished with bogies that ride along rails.”

What Are the General Terms Defined by the ASME B30.3 Tower Cranes Standard?

In addition to the definitions of the types of tower cranes, the ASME lists a glossary of general terms in the ASME B30.3 Tower Cranes standard. The following glossary outlines the parts and operation of tower cranes.

“Accessory” is a secondary part or assembly of parts that contributes to the overall function and usefulness of a machine.

“Administrative or regulatory authority” is a governmental agency, or the employer in the absence of applicable governmental jurisdiction.

“Axis of rotation” is the vertical line about which a crane swings.

“Balance” is the condition of the superstructure of a tower crane necessary for climbing; the load or the luffing boom is positioned at that radius which causes the vertical moment of the superstructure about the balance point to go to zero.

Crane Base Types and Terms

“Ballast” is the weight added to a crane base to create additional stability; it does not rotate when the crane swings.

“Anchor bolt base” refers to a crane base that is bolted to a footing.

“Expendable base” is for static-mounted cranes, a style of bottom tower section or member that is cast into a concrete footing block; all or part of this component is lost to future installations.

“Fixed ballasted base” is a crane base that is a ballasted platform that does not travel.

“Knee-braced base” is a crane base that uses diagonal members to spread the loading.

“Base tower” is a mounting accessory to secure the bottom of the tower to a foundation, structural support, travel, or ballasted base.

“Traveling base” is a crane base that is a ballasted platform mounted on bogies that ride along rails.

“Bogie” is an assembly of two or more axles arranged to permit both vertical wheel displacement and an equalization of loading on the wheels.

“Tower brace” is a structural attachment placed between a crane tower and an adjacent structure to pass loads to the adjacent structure and permit the crane to be erected to greater than freestanding height.

What Components and Structures Make Up Tower Cranes?

There are dozens of parts that make up a tower crane, and in this section, we break down the following:

- Components of a tower crane

- Structural materials

- Operational structures

- Process terms

- Load handling

Components of a Tower Crane

“Brake” is a device, other than a motor, used for slowing or stopping motion by friction or power means.

“Braking means” is a method or device for slowing or stopping motion.

“Buffer” is an energy-absorbing device for reducing impact when a moving crane or trolley reaches the end of its permitted travel.

“Cab” is a housing provided for the operator and containing the crane controls.

“Clutch” is a means for engagement or disengagement of power.

“Control station” is the location of the crane function controls, either cab mounted or by remote control.

“Drum” is the cylindrical member around which rope is wound for lifting or lowering a load.

“Guy rope” is a fixed-length supporting rope intended to maintain a nominally fixed distance between the two points of attachment. Also, it may be called a “stay rope,” “standing rope,” or “pendant.”

“Pawl” or “dog” is a device for positively holding a member against motion in one or more directions.

“Pendant” refers to a rope or bar of specified length with fixed end connections.

“Pitch diameter” is the diameter of a sheave or rope drum measured at the centerline of the rope.

“Remote control” is a radio or cable control device used to activate the crane control functions.

“Rope” refers to wire rope, unless otherwise specified.

“Rotation-resistant rope” is wire rope consisting of an inner layer of strands laid in one direction, covered by a layer of strands laid in the opposite direction. This has the effect of counteracting torque by reducing the tendency of the finished rope to rotate.

“Running ropes” are ropes that spool on / off drums.

“Sheave” is a grooved wheel or pulley used with a rope to change the direction and point of application of a pulling force.

“Wedge” is a tapered device used to provide stability.

Structural Materials

“Climbing cross-member” is a structural member attached to the end of the hydraulic cylinder used to engage the climbing ladders or lugs via pawls to raise or lower the crane structure.

“Climbing frame” is for freestanding, braced, or guyed cranes, and is a structural frame supporting the superstructure which surrounds the tower and contains arrangements to raise the frame and superstructure of the crane for insertion of an additional tower section. For internal climbing cranes, it is a frame used to transmit operational and climbing reactions to the host building frame.

“Climbing ladder” refers to a steel member with crossbars (used in pairs) suspended from a climbing frame and used as jacking support points when some cranes climb.

“High strength bolts” are high strength tensile bolts used in the assembly of crane sections. The bolts are installed in tension, by torquing or other means, at a level greater than that produced by in- or out-of-service loads for the purpose of reducing the likelihood of bolt fatigue failure.

“Maximum reach” is the maximum horizontal or vertical distance of the crane configuration, including the load hook, rigging, lifting devices, and load, can reach during lifting or boom raising / lowering operations or when weathervaning.

“Parking track” for rail-mounted cranes is a section of track supported so that it is capable of sustaining storm-induced bogie loads. It is provided with storm anchorages when required.

“Tower” refers to a vertical structural frame consisting of columns and bracing capable of supporting a superstructure with its working and dynamic loads and transmitting them to the supporting surface or structure.

Operational Structures

“Counterjib” is a horizontal member of a crane on which the counterweights, and usually, the hoisting machinery, are mounted.

“Counterweight” refers to the weights added to a crane superstructure to create additional stability or to counter the effects of the lifted load. They rotate with the crane as it swings.

“Crane” in this standard refers to “tower cranes,” which are lifting machines consisting of a tower with a superstructure that rotates and includes a load, luffing boom, or jib, and on some cranes, a counterjib extending in the opposite direction to the load, luffing boom, or jib.

“Crane configuration” is the post-erected or climbed arrangement of the crane, including jib or boom, tower sections, counterjib, and counterweights.

“Superstructure” is the portion of the crane that rotates.

“Tie-in” is a structural support consisting of a collar that surrounds the tower that utilizes bracing to attach to the host structure.

“Trolley” is the component of the crane that moves along the jib of a hammerhead tower crane and positions the load radially.

Process Terms

“Climbing” refers to freestanding, braced, or guyed cranes, and is the process whereby the height of the tower is increased by adding sections at the top for internal climbing cranes, the process whereby the entire crane is raised or lowered on or within a structure which is under construction.

“In-service” refers to the condition of a crane ready for or engaged in work with an operator at the controls.

“Normal operating condition” is the condition during which a crane is performing functions within the manufacturer’s operating recommendations. Under these conditions, the operator is at the operating controls, and no persons other than those appointed are on the crane.”

“Operational aid” refers to a device that provides information to facilitate operation of a crane. Examples of such devices include, but are not limited to, the following: luffing boom angle or hook radius indicator, trolley radius indicator, load moment indicator, and wind velocity device.

“Out-of-service” is the condition of a crane when unloaded, without power, with the controls unattended, and prepared to endure winds above the in-service level.

“Overturning moment” is the summation of the individual moments that add to the tipping tendency of a crane about its fulcrum.

“Qualified person” refers to a person who, by possession of a recognized degree in an applicable field or a certificate of professional standing, or by extensive knowledge, training, and experience, has successfully demonstrated the ability to solve or resolve problems relating to the subject matter and work.

“Unattended” is a condition in which the operator of a crane is not at the operating controls.

“Weathervaning” is the releasing of swing brakes to allow wind-induced rotation of a crane superstructure, when out-of-service, to expose minimal surface area to the wind.

Load Handling

“Dynamic loading” refers to loads introduced into the machine or its components by forces in motion.

“Jib” is the horizontal structural member attached to the rotating superstructure of a crane on which the load trolley travels when changing load radius.

“Jib point” is the outward end of the load-bearing jib.

“Lifting device” is equipment used for lifting loads as defined in the ASME B30.20 Below-the-Hook Lifting Devices standard.

A “limiting device” is operated by some part of a power-driven machine or equipment to restrict loads, or motions of the machine or equipment.

“Load” refers to the total superimposed weight on the hook.

“Load block” is the assembly of the hook, swivel, sheaves, pins, and frame suspended by the hoisting rope.

“Luffing boom” is a member hinged to the rotating superstructure that raises and lowers to change load radius and is used for supporting the hoisting tackle.

“Luffing boom stop” is a device used to limit the angle of the luffing boom at the highest recommended position.

“Radius” or “load” is the horizontal distance from a projection of the axis of rotation to the base of the crane, before loading, to the center of the vertical hoist line or tackle with load applied.

“Rated load” or “load rating” refers to the maximum allowable working load designated by the manufacturer. Rated loads are expressed in pounds, kilograms, short tons, or metric tons.

“Swing” or “slew” is the rotation of the superstructure for movement of loads in a horizontal direction about the axis of rotation.

“Trolleying” is the motion of the trolley on the jib to locate the load at a working radius.

“Two-blocking is the condition when the load block or hook assembly comes in contact with the trolley or luffing boom tip sheave.

What Other Terms Should You Know?

The ASME B30.3 Tower Cranes standard has several other terms you should know, including:

“Standby crane” is a crane that is not in regular service, but that is used occasionally or intermittently as required.

“Crossover points” are the points of rope contact where one layer of rope on a rope drum crosses over the previous layer.

A “dedicated spotter” is a qualified signalperson who has direct and unrestricted contact with the operator and whose sole responsibility is to verify that the specified clearance(s) is maintained.

“Documentation” refers to the organized collection of information that describes the structure, design, purpose, operation, maintenance, and safety requirements for the crane and includes the stickers, placards, and labels that provide operational or safety-related information.

An “equalizer” is a device that compensates for unequal length or stretch of a rope.

“Flange point” is the point of contact between the rope and drum flange where the rope changes layers on a rope drum.

A “track gage” is the horizontal distance between two rails, measured perpendicular to the direction of travel.

“Rail clamp” is a device for fastening a traveling crane to its rails to limit wind-induced travel.

“Reconfigure” is the addition or deletion of jib, luffing boom, or counterjib sections while the crane is erected.

“Shall” is a word that indicates the rule is mandatory and must be followed.

“Should” is a word that indicates the rule is a recommendation, the advisability of which depends on the facts in each situation.

“Slewing moment” is the moment acting in a horizontal plane about the centerline of rotation, induced by the slewing and brake mechanisms of the crane.

“Specified clearance(s)” is the distance in feet from an electrical conductor.

“Structural competence” is the ability of the machine and its components to withstand imposed stresses.

What Can Mazzella Do to Help You Stay in Compliance with the ASME B30.3 Tower Cranes Standard?

Mazzella partners with a third-party company, Industrial Training International (ITI), to provide training for crane operators. ITI training courses are offered for mobile cranes (including boom truck, carry deck, rough terrain, and crawler cranes), overhead cranes, articulating boom cranes, pedestal cranes and tower cranes.

ITI offers Tower Crane Certification that provides training to prepare its participants for exams from the National Commission for the Certification of Crane Operators (NCCCO). This is a four-day, in-person training course at ITI’s Morrow Crane Training Center in Salem, Oregon. Additionally, ITI offers a three-day, instructor-led tower crane safety and inspection course.

Tower Crane Ropes

Also, Mazzella is a one-stop-shop for high-performance crane ropes, or any kind of specialty ropes. We have fittings and sockets that can be installed in the field, and a large inventory of ropes in stock that allows us to help get you back up and running as quickly as possible.

Mazzella has one of the largest specialty rope inventories in the United States…ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM (original equipment manufacturers) assemblies:

- In sizes from ¼” to 3” diameter and 9mm to 52mm diameter

- Domestic and Non-Domestic

- In stock and ready for same or next-day shipment from one of our many service centers

In addition to crane ropes installations and inspections, Mazzella has the capabilities to do button and OEM socket installations. We have technicians around the country who have been trained to do:

- Socket installs

- Perform crane rope inspections

Call us at 800.362.4601 or click here if you need wire rope products or assemblies.

Crane Ropes

One Brand of Rope Will Not Work on Every Machine!

Mazzella stocks a large inventory of high-performance wire ropes available for immediate delivery.

Copyright 2023. Mazzella Companies.