What is Arch Beam and Why is it So Dangerous on an Overhead Crane?

During the 1960’s, crane beam manufacturers ceased production of arch beam/window track for their runway and bridge beams. Unfortunately, these types of track systems are still prevalent in older manufacturing facilities today and could pose a real danger to employees working nearby.

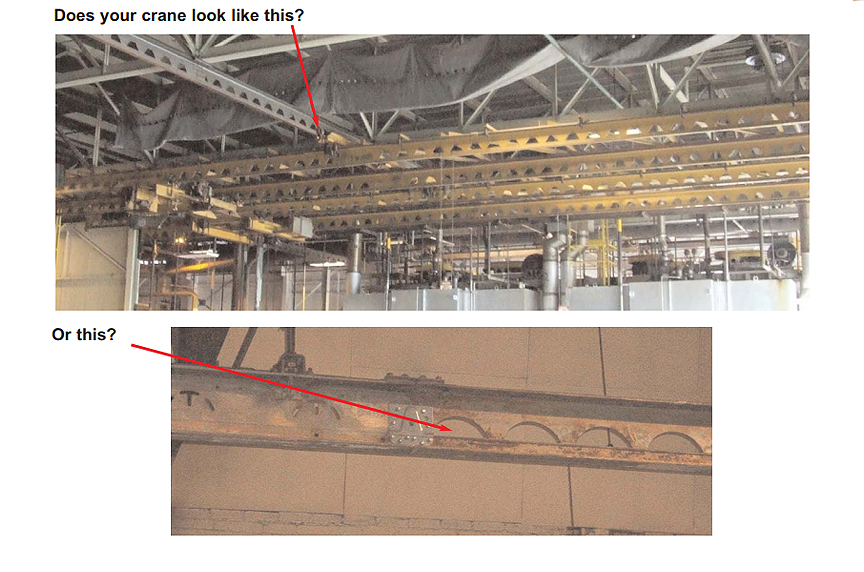

Arch beams, window track, zipper track, serrated track, or castellated beams…whatever you choose to call them, you need to be aware of what they are, and why they’re considered dangerous if they’re still being used on an overhead crane in your facility.

Unfortunately, our Overhead Crane Service group sees overhead cranes still using this dangerous and obsolete track system today, so our goal for this article is to help you understand:

- The origin and construction of these types of overhead crane tracks

- Why they’re dangerous and can no longer be recommended for use by the manufacturers

- Your options for replacing the track and/or developing a regular and intensive inspection program

Why Was Arch Beam or Window Track Used on an Overhead Crane System?

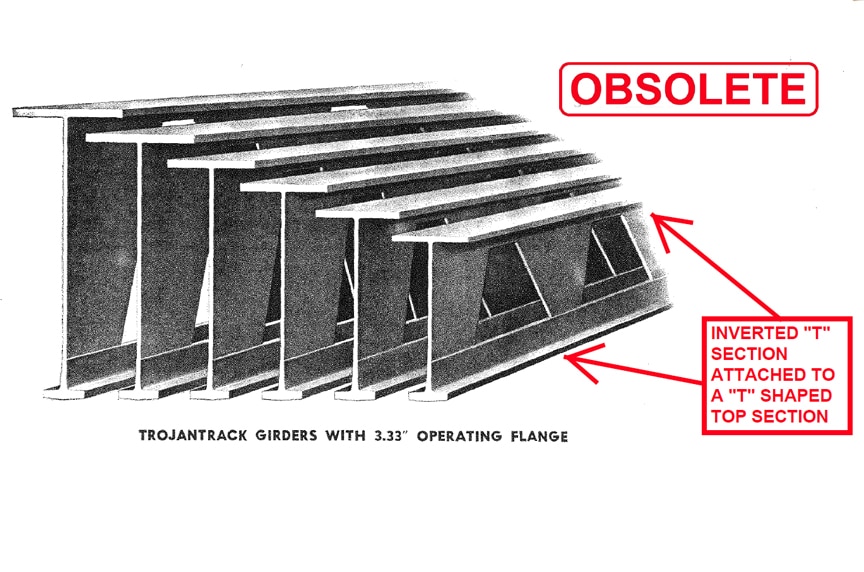

In the early to mid-1900’s, arch beams were a popular style of support beam used for a crane’s runway track and bridge. The design of an arch beam consists of an inverted “T” shaped section welded to a separate “T” shaped top section, which then creates multiple “arches” or “windows” throughout the length of the beam.

The lower section consists of a hardened metal flange designed for an under running crane to run on. The reason they were so popular is that they were strong enough to support higher duty cycle cranes, but also fairly inexpensive because they used less material.

During the 1960’s, overhead crane beam manufacturers ceased production arch beam/window track for their runway and bridge beams and have not made this style beam or track since. Unfortunately, these types of track systems are still prevalent in older manufacturing facilities today.

If you’re keeping track at home, this means that any type of overhead crane system still utilizing arch beams, is relying on material that could be over 60 years old to support the full dead weight of the crane and its load!

These types of arch beams were perfectly safe and acceptable for a long time, but as they age, the metal begins to fatigue from the stresses of decades of use. As the metal fatigues, the welds begin to weaken where the window portion of the beam attaches to the lower track. If even one weld weakens to a point where it gives way, the top beam actually peels away from the bottom of the beam—creating a “zipper effect” that occurs all of the way down the length of the bridge or runway.

As you can imagine, this can result in a catastrophic failure of the entire overhead crane system, which could potentially injure or kill workers below, and also cause unimaginable damage to the building, raw materials or inventory, and any nearby equipment or machinery.

Around 1992, Gorbel/Cleveland Tramrail made this recommendation stating:

- Loading Tables in old catalogs were calculated for new beam as built at that time.

- As of this date (March 2, 1992), all Arch Beam should be replaced with Tarca® due to its age, and De-Rating of capacity is no longer advised.

- Arch Beam should also be replaced with Tarca® versus ANY repair due to age and many years of fatigue.

The major concern with any facility still using arch beam is that the product has reached and exceeded any expectation of a reasonable service life.

At this point and time, the manufacturers of these types of track systems will not recommend their use for any type of application and will not ship any repair parts for these systems.

What if Your Crane is Still Equipped with Arch Beam or Window Track?

Again, most manufacturers of these types of systems recommend a full replacement of the track with a newer type of track system that is equivalent in design and capacity. The manufacturers will not sell repair parts, service these arch beam systems, or make recommendations on any type of way to reinforce or extend the life of these systems.

Full replacement is always recommended, but partial system replacements can be performed with the goal of replacing the entire system over a set period of time to help offset the cost.

Some large-scale production facilities may have 5,000 to 10,000 feet of this track in their building. For them, it may not be economically feasible to replace the entire track system at once. In this case, the manufacturers can recommend regular inspection and safety audits per the inspection guidelines outlined in:

- OSHA 1910.179 – Overhead and Gantry Cranes

- ANSI/ASME B30.11 – Monorails & Underhung Cranes

Gorbel/Cleveland Tramrail recommends the following steps to conduct a regular safety audit:

- Use only skilled personnel for the audit

- Identify the highest risk cranes in your inventory by age and cycles

- Study and compare the original design versus the current usage

- Fully inspect every weld in the beam. Thorough inspections, find discontinuity, and then use non-destructive testing.

- Benchmark critical components using reliability-based maintenance practices and software

Podcast: Why Arch Beams Could Pose a Real Danger to Your Employees

Mazzella Companies | Cranes 101

How Do You Inspect a Crane Equipped with Arch Beam or Window Track?

For customers who can’t justify stopping production for the amount of time a full replacement would take, they may opt to have frequent and intensive inspections performed on the crane. A visual inspection should be part of your regular crane inspection program, but there are a number of different non-destructive inspections that can be performed to provide an accurate measurement of wear or fatigue in the arch beams:

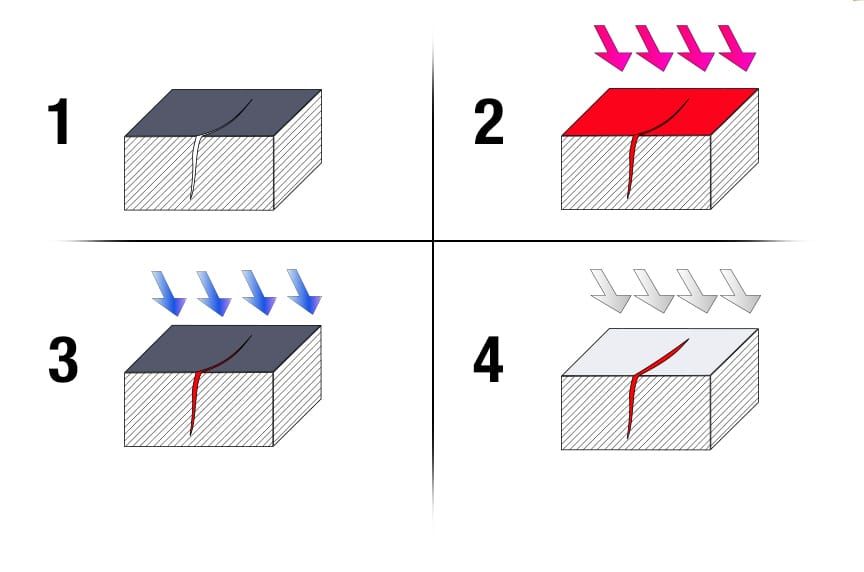

- Magnetic Particle Testing – a magnetic particle powder is used in conjunction with a magnetic field that is passed through the beam. The particle powder migrates to any micro-cracks or imperfections in the material—revealing corrosion or fatigue in the metal.

- Dye Penetrant Testing – a penetrating liquid dye is applied to the surface of the metal and allowed to soak in. The excess penetrant dye is removed from the surface and then a developer is applied to indicate fatigue cracks or any porous areas of the metal.

- Ultrasonic Testing – short ultrasonic pulse-waves are transmitted into materials to detect internal flaws to monitor corrosion, and areas of weakness or fatigue.

Magnetic particle and dye penetrant testing are essentially interchangeable and used primarily to detect and highlight surface cracks in a weld. The ultrasonic testing will identify any areas of concern within or underneath the surface of the weld and beam.

The problem with these types of testing methods is that every square inch of the beam material needs to be tested. There is no such thing as spot testing when you perform any of these tests on an arch beam—every single weld needs to be tested. On a 300 foot track, you’d have approximately 600 welds to inspect on both runway beams, so it can be a very time-consuming and expensive procedure to have done repeatedly.

It is possible to inspect sections of track at a time, rather than having the entire crane system down at once. The owner of the crane equipment would have to weigh the cost of lost production versus the higher costs of more frequent inspections being performed.

Per OSHA 1910.179 and ASME B30.11, crane usage and duty cycle will determine how often these inspections need to be performed. However, if you’re still operating a crane on an arch beam track, regardless of the duty cycle or usage of the crane, the design and materials of your crane track are well past their effective service life.

How Do You Replace the Arch Beams or Window Track on Your Crane System?

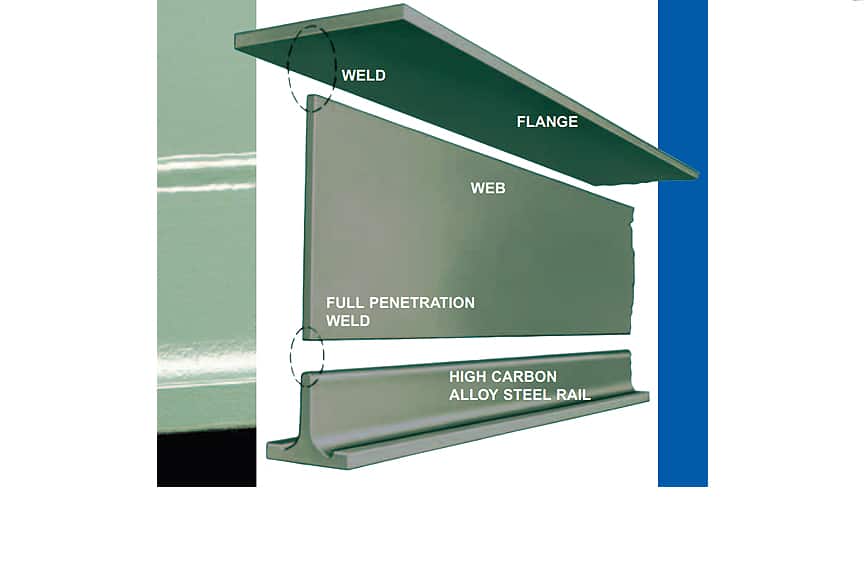

Manufacturers have tried to remain consistent in the design of the lower part of the beams and tracks so that a direct replacement beam can be installed without having to make significant changes to the existing crane design.

Often times, you can still pull the serial number off of the beams themselves and the manufacturer can reference that number to provide you with a direct replacement beam. Or, the manufacturers may still have the original purchase order in their system and can reference that to determine what type of arch beam or window track system was originally installed.

If you’re unsure of the original manufacturer, or can’t find a serial number, you can always take a picture of your track system and contact a reputable crane manufacturer or crane service company. They can help identify the type of beam and contact the manufacturer on your behalf to quote the cost of replacement beams. They can also send someone out to your facility and grab some runway beam measurements and provide these to a manufacturer to get a recommendation on a comparable replacement.

Lastly, if your bridge and components are still within required tolerances and there is no comparable beam replacement to match up with the original, then the end trucks on the bridge or the end truck wheels themselves can be replaced and matched up to a new replacement beam design.

Once you’ve made the decision to replace your arch beam or window track, a crane service company can come out and replace the entire track at once, or it can be done in sections to minimize disruption to production.

Wrapping it Up

The probability of fatigue failure in arch beam or window track systems is related to the number of stress cycles encountered during the life of the equipment. Since these types of systems are at least 50 years old, the condition of any type of arch beam or window track is difficult to determine without frequent and intensive inspection programs.

If your facility is still operating a crane running on arch beam or window track, serious consideration should be given to immediate replacement, or at the very least, a plan should be put in place to begin systematically replacing it. While the track was at one time a reliable and innovative solution in the material handling industry, this design has reached and exceeded its effective service life.

At Mazzella, we offer magnetic particle testing, dye penetrant testing, and ultrasonic testing and can help determine the suitability for continued safe use of your crane system. We also have longstanding relationships with manufacturers like Gorbel/Cleveland Tramrail and ACCO/Louden to help find a suitable replacement track that’s compatible with your existing overhead crane system.

If you’d like to schedule a consultation with a Crane Specialist, or have one of our Crane Service technicians come out to perform an inspection, please contact us today.

Copyright 2018. Mazzella Companies.