What Is BlokAlert, and How Does It Make Lifts Safer?

Have you experienced a near-miss that could have been avoided if everyone on site knew a lift was underway? Crosby’s BlokAlert System lets everyone know when a load is being lifted, which will help improve safety on your jobsite.

“Shoulda, coulda, and woulda won’t get it done.”

Legendary basketball coach and executive Pat Riley’s words hold meaning not only in the sports world, but also, other industries. That includes the lifting and rigging industry, where worker safety is of utmost importance.

“We should have known when the load was being lifted. We could have prevented this incident. Our workers would have been okay if we took more steps to enforce safety.”

If you’ve ever heard these phrases on a jobsite, or even uttered them yourself after workers suffered injuries or worse because they weren’t aware a lift was being conducted, there are ways to prevent them from being said again.

As part of the BlokCam line, The Crosby Group has created the BlokAlert System. It’s designed to warn you when a lift is being conducted.

In this article, we’ll answer the following questions:

- What is the BlokAlert System?

- Why would you use the BlokAlert System?

- How does the BlokAlert System work?

- What are the design elements of the BlokAlert System?

- What is included in a BlokAlert System order?

What Is the BlokAlert System?

The BlokAlert is a wireless, audio-visual warning system that can be deployed quickly to the hook block of a crane.

When activated by the lifting crew, the BlokAlert receiver gives out a recognizable audio-visual warning signal. The distinct alarm system can be seen and heard by site personnel in proximity to the hook block or load.

This forewarns the workforce to the position and movements of the hook block. Additionally, it increases awareness and reduces the risk of being struck by the crane’s hook block, lifting accessories, or load.

Why Would You Use the BlokAlert System?

In doing their research for the BlokAlert project, The Crosby Group found traditionally, the distance between the horn, often located near the operator’s cab, and the load, is inconsistent and does not efficiently warn site personnel to the position of the hook block or load.

The same could be said for airhorns or whistles when used by riggers. In both scenarios, the attention of the work force is diverted to where the sound is coming from, as opposed to the hazard.

Crosby created a solution to fit a warning system to the hook block. When activated, the consistent proximity between the hook block and load enhances the efficiency of the warning system and draws attention to the hazard, not away from it.

The BlokAlert System is compatible with a variety of cranes.

What Is Included in a BlokAlert System Order?

When you order a BlokAlert System, you will get the following:

- Receiver

- Fob

BlokAlert Receiver

The BlokAlert Receiver (BA-R1) features an LED beacon and is capable of producing up to 528 unique audible warnings. This audio-visual warning system combines functionality and performance with design.

Excluding the antenna, the BlokAlert Receiver is:

- 6.82” (173 mm) in height

- 8.27” (210 mm) wide

- Features a depth of 3.39” (86 mm)

- Weighs 7.5 lbs. (3,400 grams)

BlokAlert Fob

The BlokAlert Fob (60009) is a four-button remote that allows riggers to operate multiple BlokAlert systems across your jobsite.

You will receive two four-button fobs per system. Each comes with a rugged design and a neck lanyard. Note that eight- and 16-button fobs are available upon request.

BlokAlert Accessories

Along with the receiver and fob, the BlokAlert can be purchased with the following accessories:

- BlokAlert Transmitter (BA-T2)

- BlokAlert Footswitch (FS1)

BlokAlert Transmitter (BA-T2)

Through the use of a footswitch, the BlokAlert Transmitter gives the crane operator hands-free operation of the BlokAlert System.

BlokAlert Footswitch (FS1)

The BlokAlert Footswitch provides the hands-free operation of the BlokAlert Transmitter. It offers end-users quick and easy installation.

How Does the BlokAlert System Work?

If activated by the lifting crew or a rigger, the signal is transmitted from the fob to the receiver on the crane’s hook block.

If the crane operator is controlling BlokAlert via a Footswitch, the Transmitter is activated from the crane cab. When operated, the signal is transmitted to the Receiver on the hook block of the crane.

Regardless of where the signal comes from, once the signal is transmitted, the Receiver is activated. This alerts the workforce to the proximity of the hook block.

What Are the Design Elements of the BlokAlert System?

The BlokAlert System comes with the following design elements:

- High-powered neodymium magnets

- Equipment that is easy to install, remove and charge

- Two hand-held transmitters per system

- Easy-to-use, multifunction operation

- Two 78-107 decibel electronic sounders

- 180° LED beacon

- Choice of four beacon colors

- Blue

- Orange

- Red

- Green

- Pair your transceivers with the push of a button

- Built-in lithium-ion battery with 124-hour battery life

- Built-in, fold-away carry handles

- Long-range transmitter and receiver

- Purpose-built aluminum housing

- Built-in lanyard anchors

- Safety lanyard that provides secondary security tethering

- LED power indicator

- 86mm low-profile design

- Durable all-weather design manufactured to an IP67 rating*

- -10°C to 50°C (14°F to 122°F) operating temperature

- Easy-access fuse

- High-quality industrial charge connector

- Optional cab transmitter

- CE and FCC approved

*By being IP67 rated, the BlokAlert System is completely protected from dust contact and protected against water submersion up to 1m.

How Can Mazzella Help with Your Lifting and Rigging Needs?

In the United States, the law stipulates company management is responsible for providing a safe workplace for all employees. Putting workers at risk of injury can expose employers to serious liability in the event of an accident.

By controlling or eliminating hazards in the workplace, you help reduce the risk of an accident. Think about how quickly the costs of a workplace accident or fatality can add up, including:

- Lost wages

- Workers’ compensation

- Low employee morale

- Decrease in productivity

- Workforce shortages

- Potential legal fees and OSHA fines

Through the use of technology, Crosby and the BlokAlert System have helped improve safety measures on the jobsite.

For decades, Crosby has manufactured products designed to make the lifting and rigging industry safer. Similarly, Mazzella has the mission to provide you with quality products that are the right fit to increase your productivity and minimize your safety risks.

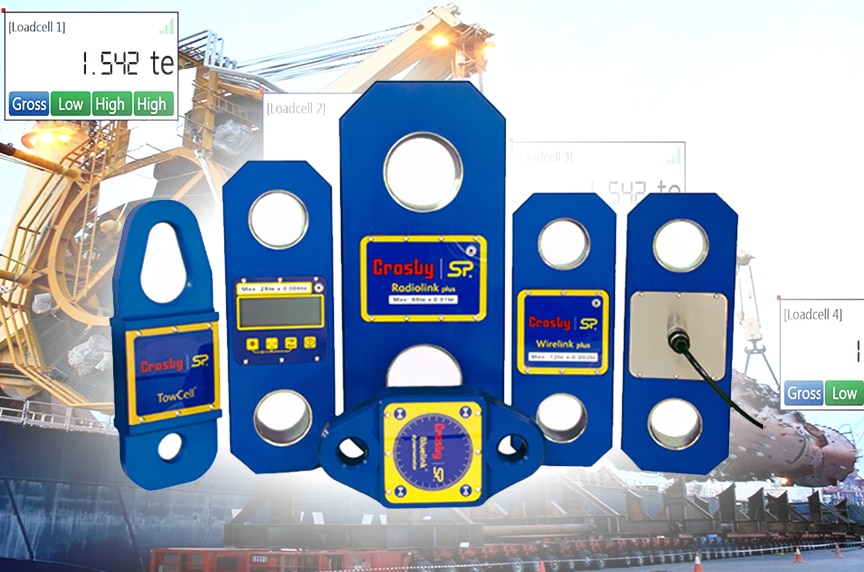

Mazzella is a distributor of Crosby products of all types, including but not limited to:

- Radiolink Plus and BlueLink Load Cells

- Wireless Load Shackle

- BlokCam

- Verton

- Crosby Gunnebo GrabiQ Chain Slings

- Clamps

- Shackles

- Wire Rope Clips

- Pipe Grabs

- Sheaves

- Bearings

- Blocks

- Sling Saver Hardware

- Turnbuckles

- Hooks

- Thimbles

Call us at 800.362.4601 or click here if you want to learn more about or inquire about buying a BlokAlert System!

Crosby | Straightpoint Load Cell Dynamometers

Crosby designed the Radiolink Plus to be rigged with Crosby standard shackles. Straightpoint’s DNV-GL type approved wireless tension load cell is capable of weighing and dynamic load monitoring capacities from 1t to 500t (all in stock).

Copyright 2023. Mazzella Companies.