Why You Should Buy Below the Hook Devices and Overhead Cranes Together

Learn the long-term benefits of integrating a below-the-hook lifting device with your overhead crane

In many industries, companies will invest heavily in overhead cranes to improve safety, increase throughput, and reduce manual handling. But these companies often overlook how their loads will actually be handled.

It’s common for companies to purchase overhead cranes first, then realize they will need a below-the-hook lifting (BTH) device to improve their processes. While you can modify the existing crane, these modifications can cost you thousands of dollars and can lead to compatibility issues.

We understand the effort and resources it takes to install and maintain an overhead crane. We also want to ensure you get the most out of that investment.

That’s why in this article, with the help of our BTH and overhead crane experts, we’re going to explain why you should buy a BTH device and overhead crane together.

What Are Below-The-Hook Devices, and Are They Required for Every Lift?

In practical terms, a below-the-hook lifting device is used when the load does not lend itself to conventional rigging, when the lift needs better control, or when the process demands repeatability.

But are they required for every lift? No. Traditional rigging can be appropriate for straightforward loads that were designed with lift lugs and clear vertical pick conditions.

The value comes from evaluating the application and selecting the lifting method that best matches safety, productivity, and long-term operational needs.

What are Common Crane Design Mistakes?

Beyond capacity, other practical design considerations are often overlooked, including:

- Hook and bail compatibility: can the hook accommodate the bail size used on the lifting device?

- Electrical provisions for motorized lifters

- Control integration

- The number of people required, and the time required per lift

- Future growth, including whether the crane is likely to be used for heavier loads or different processes later

These topics can easily fall through the cracks if not discussed at the beginning of the design process.

What If You Purchase Cranes and Lifting Devices Separately?

Buying the overhead crane first and addressing below-the-hook needs later often creates friction.

1. No Capacity for the Lifter Weight

A facility may plan to lift a 5-ton load and assumes standard rigging will be used. Later, the operation demands a more efficient method, such as a powered lifter. That device can weigh significantly more than chains or slings, and the crane may no longer have sufficient remaining capacity once the device weight is included.

If the crane is already installed, the facility may have limited options. They may be forced to keep an inefficient workflow, accept lower capacity handling than desired, or pursue an expensive rework.

2. Missing Electrical Provisions

If a future below-the-hook device will need electric power, the crane should be equipped for that possibility during the build. Adding power provisions after installation tends to be more expensive than integrating them in the shop during fabrication, and it can create unplanned downtime.

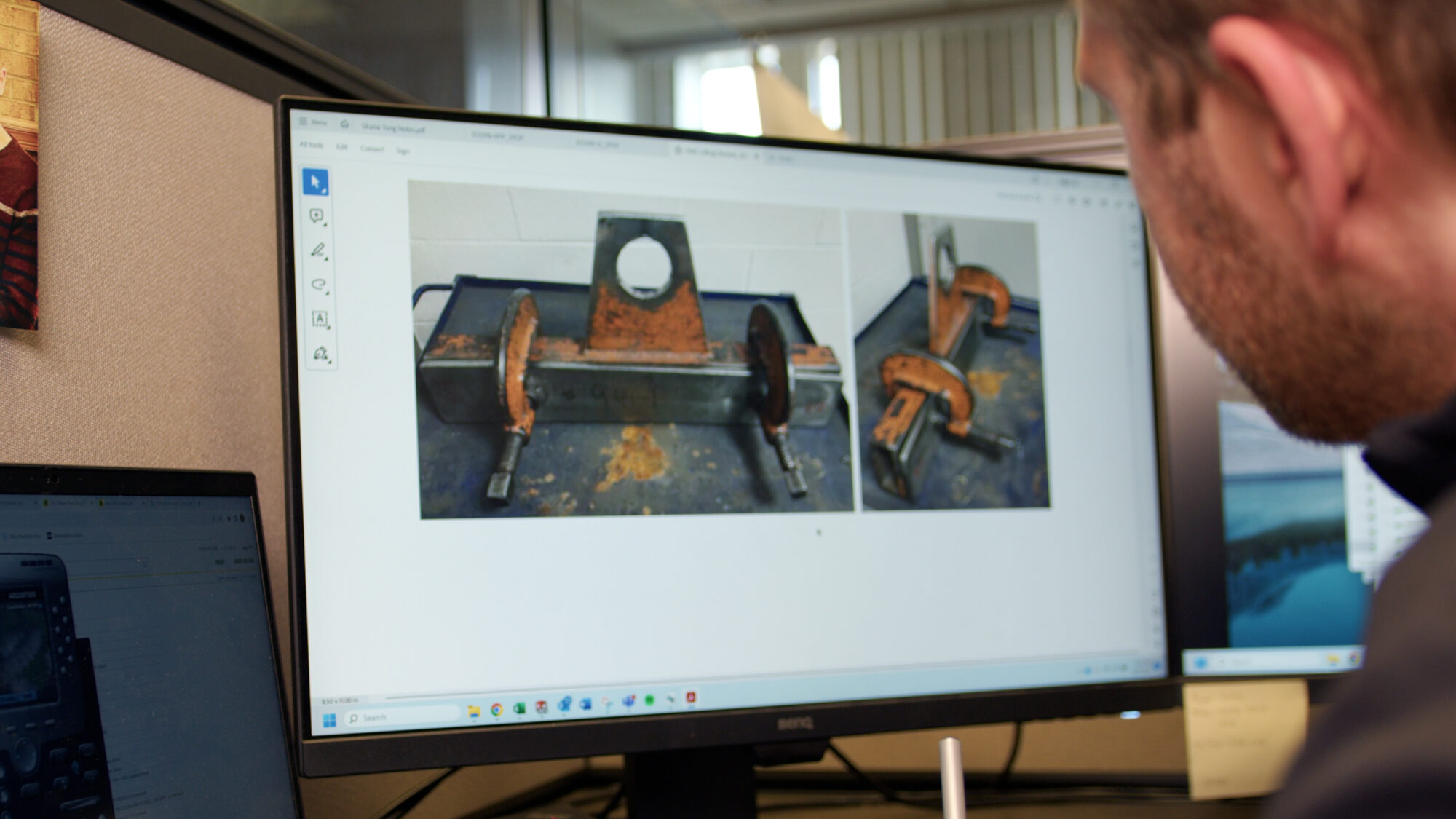

3. Hook and Bail Mismatch

A below-the-hook device must interface correctly with the crane hook. If the hook throat or geometry cannot accommodate the bail size required for the lifter, the team may be forced into modifications, redesign, or compromises that could have been avoided with early coordination.

4. The Process Remains Labor-Heavy

A team starts with traditional rigging and discovers that the process takes multiple people to hook up, stabilize, and operate safely. Later, the facility wants a one-person, hands-free workflow, but the crane was not designed to support the required equipment. The result is that the operation stays labor-heavy, slower than expected, and difficult to standardize.

5. Expensive Retrofitting

Even when modifications are possible, field changes typically carry a premium due to labor, travel, coordination, and service scheduling. The crane is already in the facility, so work may require special access and production disruption. When equipment is built as a system in the shop, integration is easier to plan, verify, and execute.

Why Should You Buy a Crane and BTH Device Together?

Pairing an overhead crane and below-the-hook lifting device in the same project creates a single engineered lifting system rather than two separate purchases. The advantages show up in multiple areas.

1. Improved Safety

When the crane, hoist, lifting device, and load are engineered as a complete system, safety decisions are based on actual use conditions rather than assumptions. The system can be designed around how loads will be lifted, moved, and positioned, including the operating constraints that matter in the real world.

An integrated design also reduces compatibility gaps that can lead to risky workarounds on the floor. Instead of asking operators to adapt to equipment limitations, the equipment is built to support the intended process.

2. Better Crane Capacity Planning

Capacity planning improves when the below-the-hook device is included early. Engineers can account for:

- Load weight plus lifter weight

- Hoist capacity requirements

- Support structure loading requirements

This avoids the scenario where a crane technically exists, but the safest lifting method is no longer feasible because the device weight consumes too much of the capacity.

3. Better Electrical and Control Integration

If the lifting device requires electric power or needs control integration, the crane can be built with the correct provisions from the start. This supports a cleaner installation, simplifies commissioning, and reduces the likelihood of later modifications.

Even if the facility is not ready to purchase the below-the-hook device immediately, designing the crane with accommodations for future powered devices can protect the investment and reduce future barriers.

4. Hook and Bail Compatibility

When systems are planned together, hook and bail interface requirements are known early. That means the crane hook selection and the lifter bail sizing can be aligned from the beginning, preventing late-stage surprises that delay projects.

5. Pre-Delivery Testing

A major advantage of integration is the ability to test the complete system before it ships. Shop testing allows problems to be identified and resolved in a controlled environment. That reduces on-site troubleshooting and helps the field installation go more smoothly.

6. Unified Engineering Process

When crane and below-the-hook specialists collaborate during the design phase, the project benefits from cross-verification. A single proposal and coordinated engineering approach reduce the back-and-forth that happens when one vendor is responsible for the crane and another is responsible for the lifting device.

How Can You Future Proof Your Overhead Crane?

When designing overhead cranes, the installers should ask you if the application and max capacity of the crane will change over time. If you discuss it with them ahead of time, they can help you future proof the crane if a BTH device is needed down the road.

Futureproofing does not always mean buying everything immediately. In most cases, it means designing the crane to accommodate a below-the-hook device that may be added later. It can also mean giving your crane the ability to add extra weight.

This approach helps prevent the difficult situation where a facility needs to change the lifting method but cannot do so without major modification or replacement.

How Expensive is Retrofitting an Overhead Crane?

The biggest hesitation for many buyers is the upfront price. Adding a custom below-the-hook device to an already significant crane investment can push a project beyond budget.

However, it is important to compare the initial price to the total cost of ownership. Separate purchasing often introduces hidden costs that do not appear on the initial crane quote:

- Field modifications that would have been cheaper in the shop

- Downtime and productivity loss during rework

- Engineering time spent solving compatibility problems

- Reduced operational efficiency if the facility stays with a labor-intensive process

A useful way to think about this is the difference between factory integration and field retrofit. When you integrate during the build, the work is done under controlled conditions, with fewer unknowns. When you retrofit later, you pay for additional labor, scheduling, and disruption.

There can also be cost benefits when multiple systems are purchased as part of a larger project. If a facility is building multiple bays or multiple cranes and needs similar lifting devices, repeating a design and purchasing volume can reduce the per-unit cost.

Also, delaying the purchase can expose the project to pricing volatility in materials and components. While markets move up and down, postponement adds uncertainty that can make budgeting harder.

When Do You Need a Below-the-Hook Device?

There is no universal rule that applies to every operation. The right approach is to review the application and determine whether traditional rigging is sufficient or whether a below-the-hook device would provide meaningful safety and performance improvements.

Traditional rigging can be a good fit when:

- The load has dedicated lift points designed for chains or slings

- The lift is a straightforward vertical pick with minimal need for manipulation

- The process does not require hands-free handling or one-person operation

- The lift is occasional rather than high-cycle

A below-the-hook lifting device is good when:

- The load does not have dedicated lift points

- The load requires manipulation during placement

- The center of gravity is off-center or difficult to control with standard rigging

- The lift is repetitive and would benefit from faster, more consistent handling

- The current method requires multiple people and could be reduced safely

- The operation wants hands-free handling to reduce exposure and improve consistency

Final Thoughts on Pairing Overhead Cranes and BTH Devices

When companies buy a crane without fully evaluating how loads will be handled, they increase the risk of capacity shortfalls, missing power provisions, compatibility problems, and expensive retrofits.

Purchasing below-the-hook lifting devices together with an overhead crane build helps close that gap. It allows the crane and the lifting device to be designed as one system, with the load and real operating requirements driving decisions. It also makes it easier to plan for future needs, reduce field modifications, and avoid costly compromises.

At Mazzella, our in-house crane and BTH experts can help you get the right lifting device for your facility. Reach out to them to learn more.

Learn More About BTH Devices and Overhead Cranes