How Much Does an Overhead Crane Inspection Cost?

Whether you’re comparing quotes or trying to budget, this page gives you the clarity most providers avoid.

You’ll see what affects inspection pricing, what’s actually included, and how to get the best value, without cutting corners or facing surprise charges. You’ll also know what to expect before anyone sets foot in your facility, with guides, tools, and FAQs to help you make the smartest decision for your team and company.

Overhead Crane & Hoist Inspection Pricing

| Crane Type | Capacity | Annual Periodic Inspection | Quarterly Periodic Inspection | Monthly Frequent Inspection |

|---|---|---|---|---|

| Single Girder Bridge Cranes |

5 Tons or Less | $108 – $141 | $108 – $141 | $72 – $94 |

| Double Girder Bridge Cranes |

5 Tons or Less | $108 – $141 | $108 – $141 | $72 – $94 |

| Single Girder Bridge Cranes |

Over 5 Tons, Up to 10 Tons |

$151 – $197 | $151 – $197 | $101 – $131 |

| Double Girder Bridge Cranes |

Over 5 Tons, Up to 30 Tons |

$151 – $197 | $151 – $197 | $101 – $131 |

| Double Girder Bridge Cranes |

Over 30 Tons, Less than 40 Tons |

$194 – $253 | $194 – $253 | $129 – $169 |

| Additional Auxiliary Hoist or Trolley |

N/A | $86 – $113 | $86 – $113 | $58 – $75 |

| Workstation Cranes or Small Gantry Cranes |

3 Tons or Less | $108 – $141 | $108 – $141 | $72 – $94 |

| Jib Cranes or Monorail Cranes |

N/A | $86 – $113 | $86 – $113 | $58 – $75 |

Custom pricing for service class E and F cranes or with a capacity greater than 40 tons.

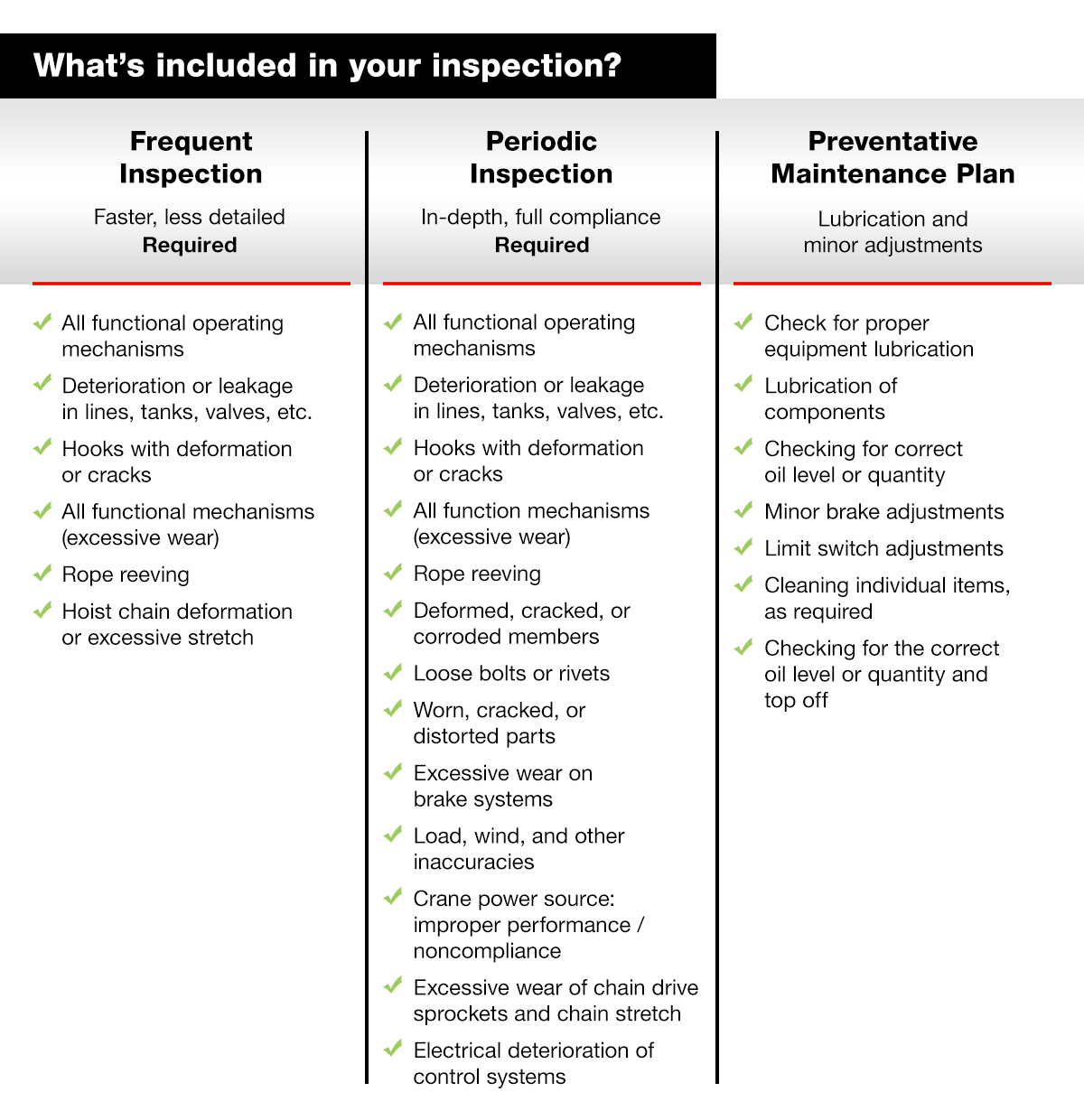

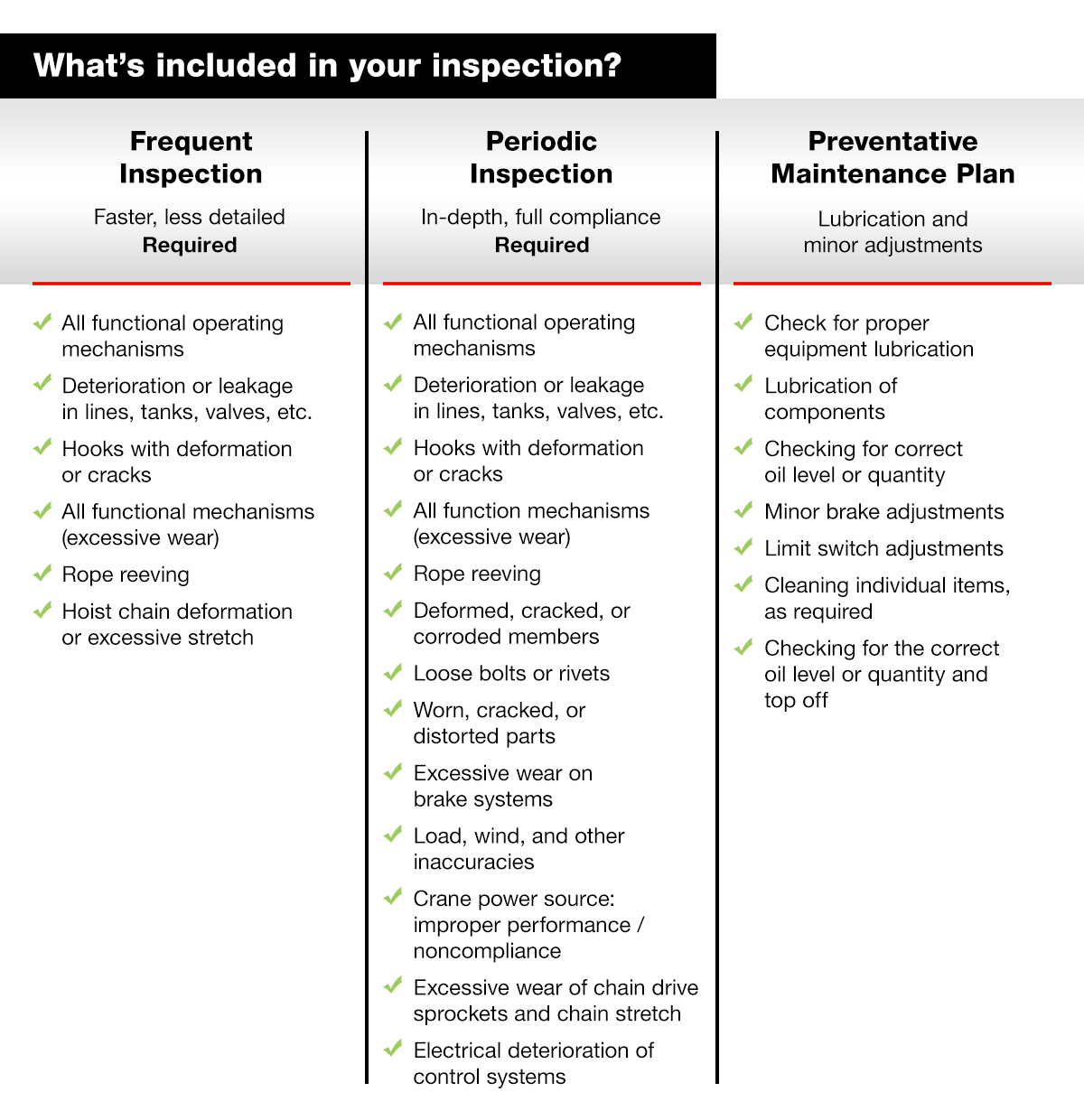

What’s Included In Your Detailed Inspection?

- OSHA, ASME, MSHA, and CMAA regulations and requirements related to your equipment.

- Inspection checklist with details outlined.

- Identification of each piece of equipment denoting tons, manufacturer, etc.

- Documenting known field changes in equipment.

- Inspection deficiency repairs will be quoted once inspections have been completed.

- Equipment adjustments, repairs, or replacements can be made with customer approval and change order.

Factors That Affect Inspection Cost

Contact Our Inspections Team

Frequently Asked Questions

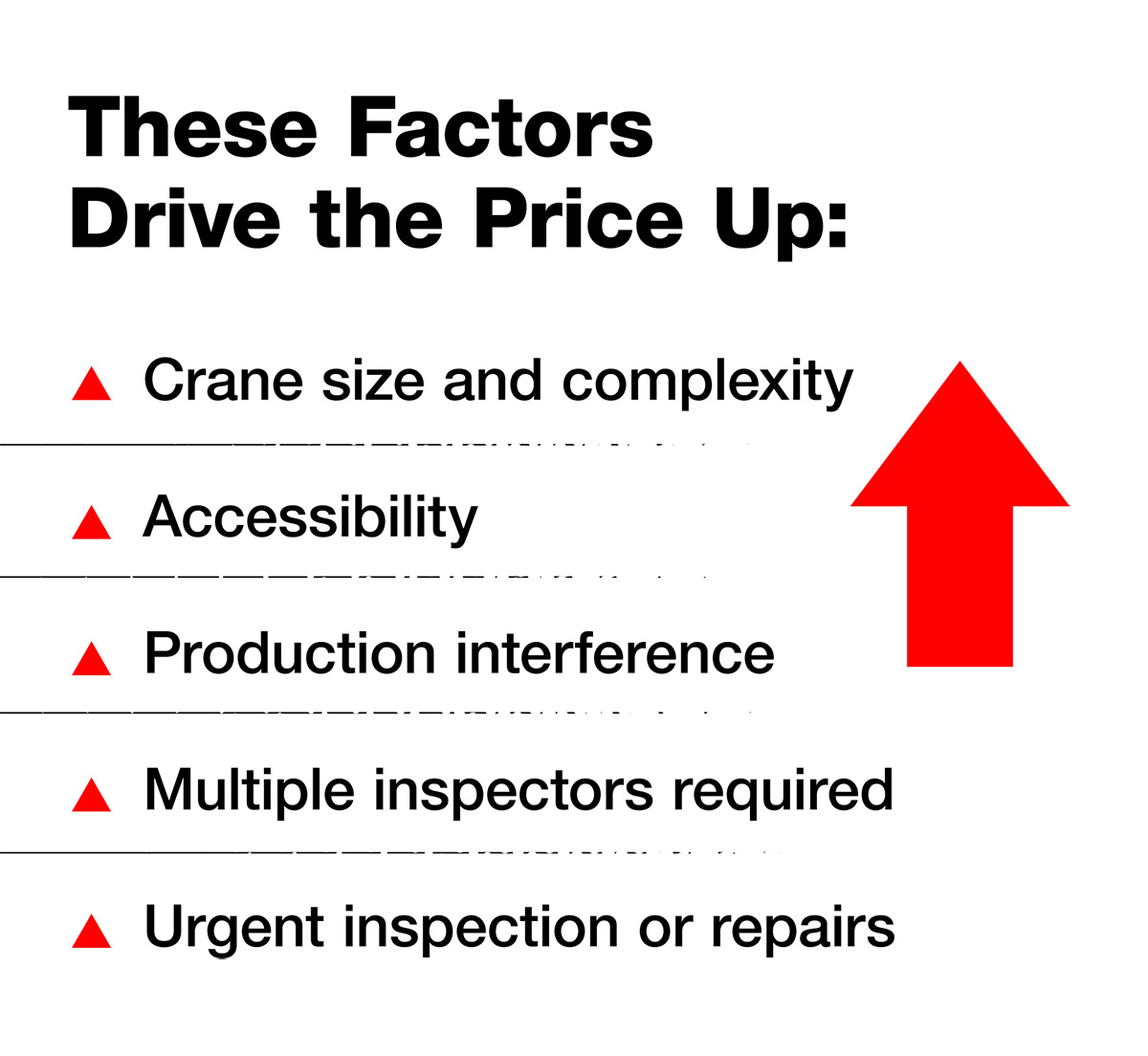

What factors drive the price up?

The cost of your overhead crane inspection depends on a number of variables:

- Crane size and complexity (Larger cranes have more components, older cranes may require more time).

- Accessibility (Cranes located > 50 feet high may require bigger manlifts or added safety. Cranes with > 75-foot span may require extra time to inspect).

- Production interference (If our inspectors need to wait on production to access the crane).

- Multiple inspectors required (For complex systems, we may deploy a two-person team).

- Urgent inspection or immediate repairs on-site.

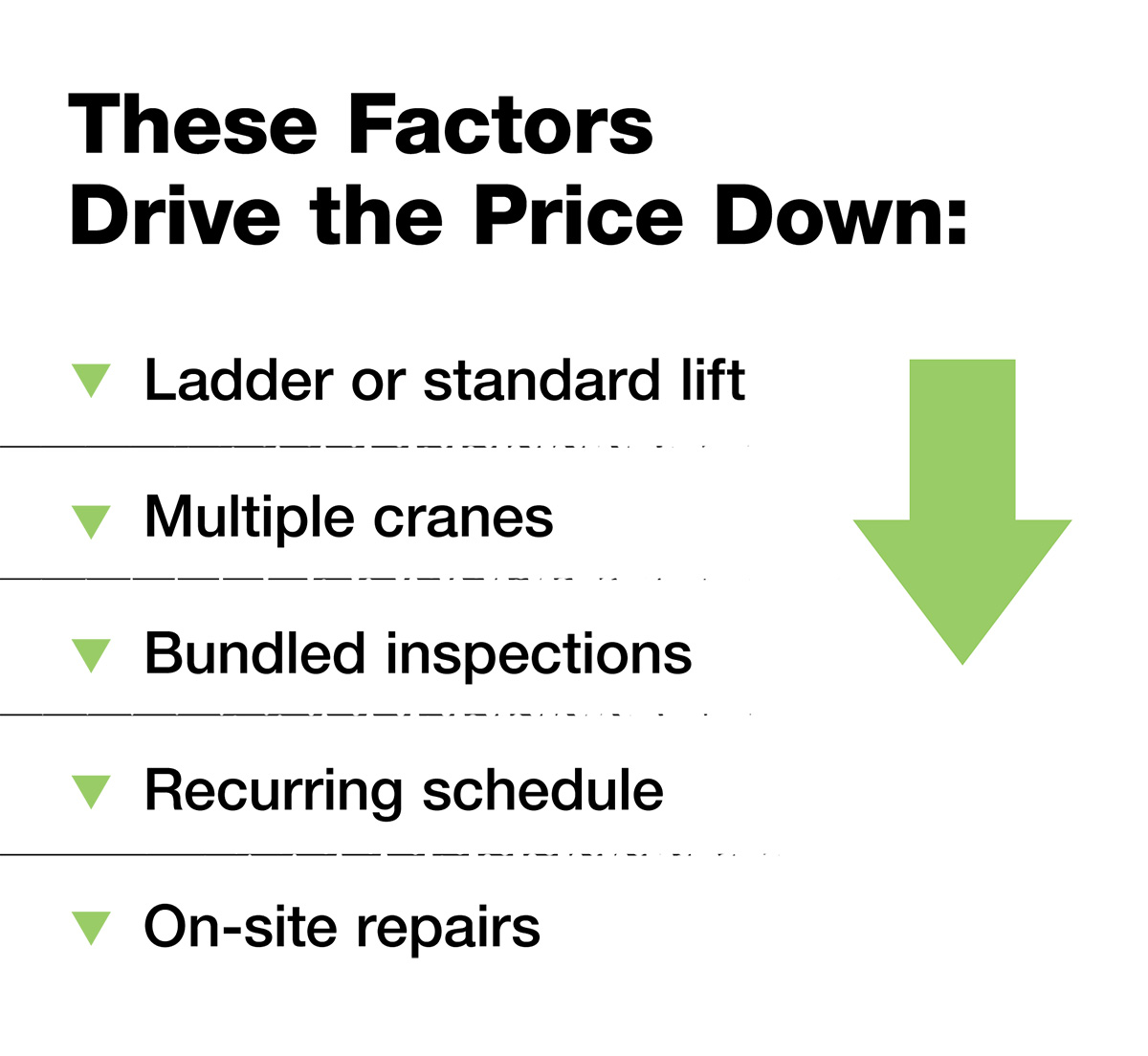

What factors drive the price down?

You may qualify for reduced pricing if:

- Your crane is accessible via ladder or standard lift.

- You’re inspecting multiple cranes at once.

- You bundle crane inspections with rigging or racking inspections.

- You establish a recurring monthly / quarterly / annual inspection schedule.

- You allow on-site repairs during inspections (eliminating future travel).

What makes some companies so expensive?

Higher-priced inspection providers often bring more value, including:

- Broader capabilities – They may be a one-stop shop for inspections, repairs, training, and parts.

- More experienced technicians – Which helps reduce downtime and improve maintenance planning.

- Stronger infrastructure – Bigger teams, faster response times, and higher availability.

- Deeper inspections – Going beyond OSHA minimums to uncover long-term risks.

- Better Reports – Detailed easy to understand inspection reports that have been developed with top industry experts.

- Bundled value – Discounts on parts, service, or ongoing maintenance programs.

- Customer prioritization – Large or long-term customers may receive preferential pricing structures.

🔎 Tip: Don’t just compare prices. Ask what’s included, how detailed the report is, and what support comes after the inspection.

What makes some companies so cheap?

Lower-cost providers may be offering a narrower or leaner service. Here’s why:

- Minimal inspections – They stick strictly to the OSHA minimum checklist.

- Fewer capabilities – No parts access, repairs, or additional services offered.

- Lower overhead – Smaller teams with fewer resources or admin support.

- Limited technician experience – May not assist with long-term maintenance planning.

- Fewer availability guarantees – Slower response time when you need help.

- Undercapacity – Companies trying to stay busy may cut prices to win work.

💡 Low cost doesn’t always mean bad — but it often means you’ll do more coordinating on your own.

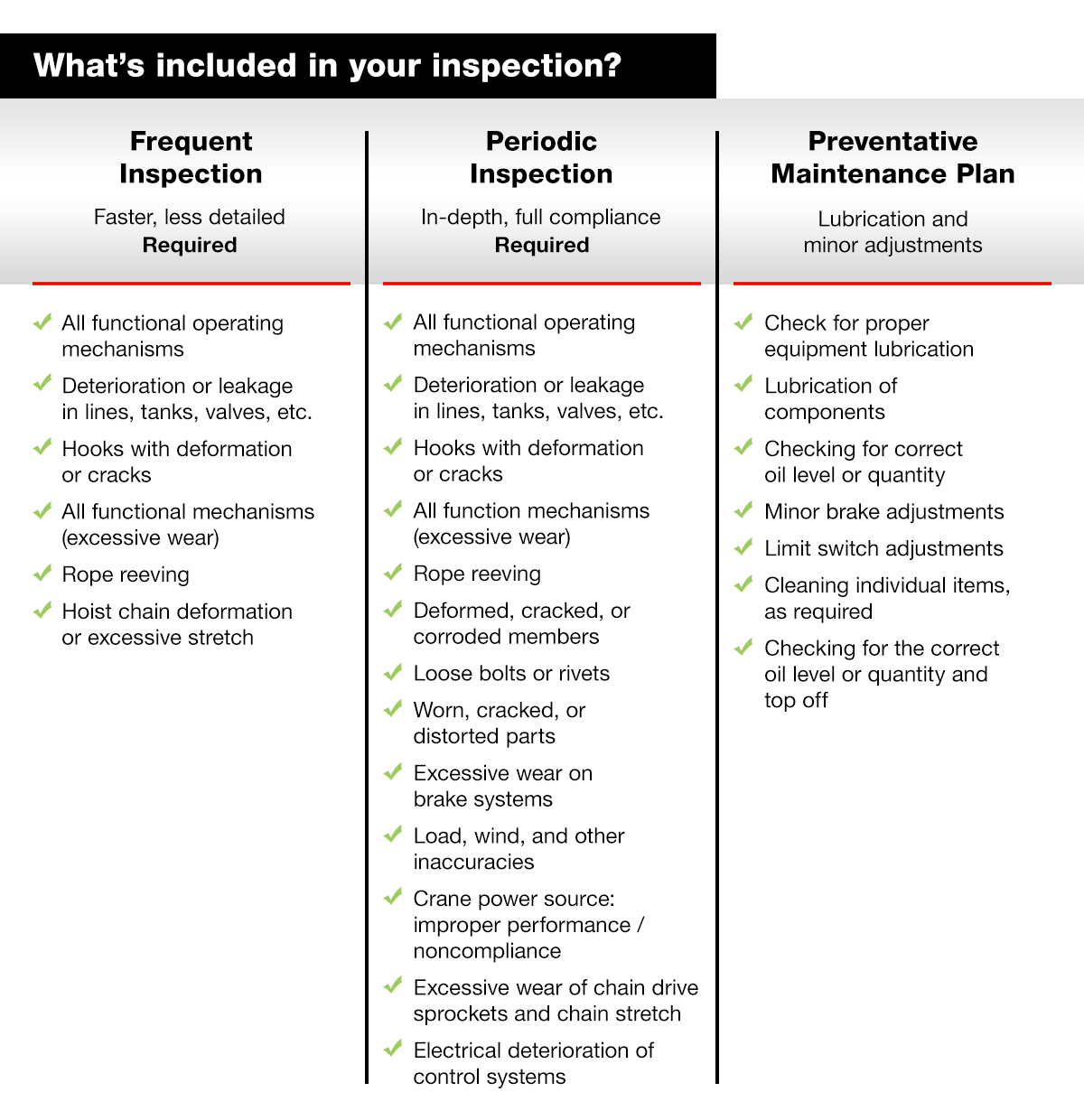

What types of overhead crane inspections do I need, and how often?

- Frequent Inspections (monthly, quarterly or more): Faster, less detailed.

- Periodic Inspections (annual or semi-annual): In-depth, full OSHA / ASME / CMMA compliance.

- Download our free Overhead Crane Inspection Frequencies Guide to see the required inspection intervals based on ASME and CMAA standards.

- Additional Compliance Options:

- Preventative Maintenance Plans.

- Bundled services: Add rigging, racking, or engineered lifeline inspections for discounted packages.

What is included in a Frequent Inspection?

OSHA 1910.179(j)(2) Frequent Inspection Items:

- (j)(2)(i) All functional operating mechanisms for maladjustment interfering with proper operation.

- (j)(2)(ii) Deterioration or leakage in lines, tanks, valves, drain pumps, and other parts of air or hydraulic systems.

- (j)(2)(iii) Hooks with deformation or cracks. Visual inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and the serial number, or other identifier, of the hook inspected. For hooks with cracks or having more than 15 percent in excess of normal throat opening or more than 10° twist from the plane of the unbent hook refer to paragraph (l)(3)(iii)(a) of this section.

- (j)(2)(iv) Hoist chains, including end connections, for excessive wear, twist, distorted links interfering with proper function, or stretch beyond manufacturer’s recommendations. Visual inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and an identifier of the chain which was inspected.

- (j)(2)(vi) All functional operating mechanisms for excessive wear of components.

- (j)(2(vii) Rope reeving for noncompliance with manufacturer’s recommendations.

What is included in a Periodic Inspection?

OSHA 1910.179(j)(3) Periodic Inspection Items:

- (j)(2)(i) All functional operating mechanisms for maladjustment interfering with proper operation.

- (j)(2)(ii) Deterioration or leakage in lines, tanks, valves, drain pumps, and other parts of air or hydraulic systems.

- (j)(2)(iii) Hooks with deformation or cracks. Visual inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and the serial number, or other identifier, of the hook inspected. For hooks with cracks or having more than 15 percent in excess of normal throat opening or more than 10° twist from the plane of the unbent hook refer to paragraph (l)(3)(iii)(a) of this section.

- (j)(2)(iv) Hoist chains, including end connections, for excessive wear, twist, distorted links interfering with proper function, or stretch beyond manufacturer’s recommendations. Visual inspection with a certification record which includes the date of inspection, the signature of the person who performed the inspection and an identifier of the chain which was inspected.

- (j)(2)(vi) All functional operating mechanisms for excessive wear of components.

- (j)(2(vii) Rope reeving for noncompliance with manufacturer’s recommendations.

- (j)(3)(i) Deformed, cracked, or corroded members.

- (j)(3)(ii) Loose bolts or rivets.

- (j)(3)(iii) Cracked or worn sheaves and drums.

- (j)(3)(iv) Worn, cracked or distorted parts such as pins, bearings, shafts, gears, rollers, locking and clamping devices.

- (j)(3)(v) Excessive wear on brake system parts, linings, pawls, and ratchets.

- (j)(3)(vi) Load, wind, and other indicators over their full range, for any significant inaccuracies.

- (j)(3)(vii) Gasoline, diesel, electric, or other powerplants for improper performance or noncompliance with applicable safety requirements.

- (j)(3)(viii) Excessive wear of chain drive sprockets and excessive chain stretch.

- (j)(3(x) Electrical apparatus, for signs of pitting or any deterioration of controller contactors, limit switches and pushbutton stations.

- Note: A visual inspection will be performed for items that require disassembly unless otherwise quoted to include disassembly and reassembly.

What’s included in a Preventative Maintenance Plan?

Preventative Maintenance Option includes: (P/M Option)

- Check for proper equipment lubrication.

- Lubrication of mechanical components where necessary such as wire ropes, rope sheaves, hook-block, crane.

- Checking for correct oil level or quantity and, when necessary, top-off of hoist and travel gears and other machinery components.

- Minor brake adjustments where necessary.

- Limit switch adjustments where necessary.

- Cleaning individual items as required for servicing.

Why should I budget for more thorough inspections?

Skipping inspections might save a few hundred dollars—but crane failure can cost you thousands per hour in downtime, OSHA fines, or safety violations. Proper inspection is an investment in uptime, safety, and long-term asset performance.

Have your inspection rates changed recently?

Our hourly rate has held steady in recent years at $115 – $150 / hour, depending on complexity. We offer fixed pricing when possible to eliminate surprises.

Do you offer custom pricing or service agreements?

We offer:

- Multi-year pricing agreements.

- Annual billing or per-inspection billing.

- Custom quotes for large facilities or high-volume needs.

![Overhead Crane Inspection Frequencies [Guide]](https://www.mazzellacompanies.com/wp-content/uploads/2024/04/resource-download-crane-inspection-frequency-guide-0324.jpg)

![Overhead Crane Pre-Inspection [Checklist]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-overhead-crane-pre-inspection-checklist-0324.jpg)

![Overhead Crane Operator Daily Inspection [Checklist]](https://www.mazzellacompanies.com/wp-content/uploads/2024/03/resource-download-crane-hoist-operator-daily-inspection-checklist-0324.jpg)