What Is Bridge Speed on an Overhead Crane, and Why Does It Matter?

Learn how bridge speed impacts safety, productivity, cost, and crane system design across industries.

Read ArticleArticles, videos, literature, downloads, and podcasts to help you learn more about lifting and rigging.

Learn how bridge speed impacts safety, productivity, cost, and crane system design across industries.

Read Article

Learn the key differences between Class 1 and Class 2 SRLs under ANSI standards, how fall clearance impacts safety, and…

Read Article

Learn the top lifting and rigging industry trends for 2026, including AI, energy infrastructure growth, inspections, automation, and workforce challenges.

Read Article

We’ve compiled a list of our 10 best articles from 2025.

Read Article

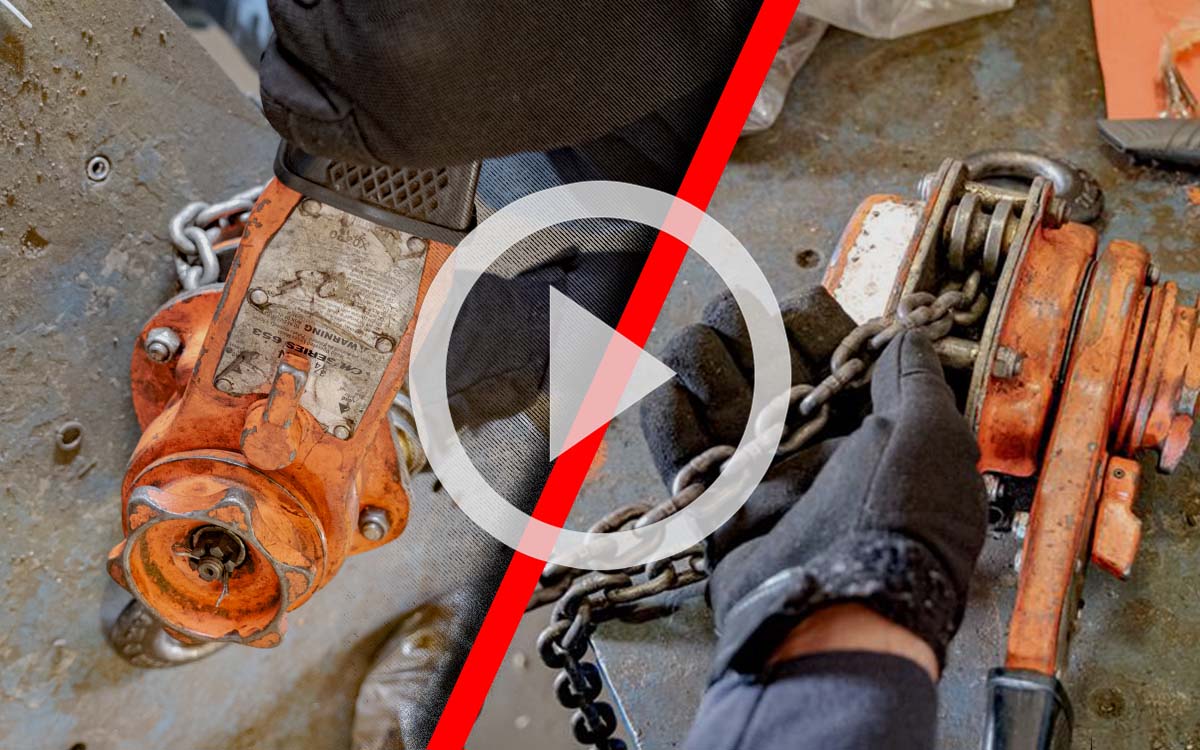

Can you replace a hoist chain yourself? Learn why hoist chains aren’t interchangeable and how using the wrong chain can…

Watch Video

P.E. vs standard lifeline inspection explained—who performs each, what’s included, and when you need a P.E. to keep your fall…

Watch Video

Explore lifting and rigging trends for 2026, from data center power demand to automation, training challenges, and cybersecurity.

Watch Video

Catch up on 2025's top lifting and rigging videos. Explore our countdown of must-watch content covering hooks, chain, cranes, and…

Watch Video

Discover the real cost of crane safety, and what happens when features get cut before the purchase order is approved.

Read More

Avoid costly crane buying mistakes. Learn how specs, duty cycle, and serviceability impact uptime and long-term ROI.

Read More

Discover inspiring stories and real advice about careers in the lifting industry from women leading its future.

Read More

Ahead of new tariff announcements, here’s what the lifting industry needs to know about sourcing, steel costs, and supply chain…

Read More