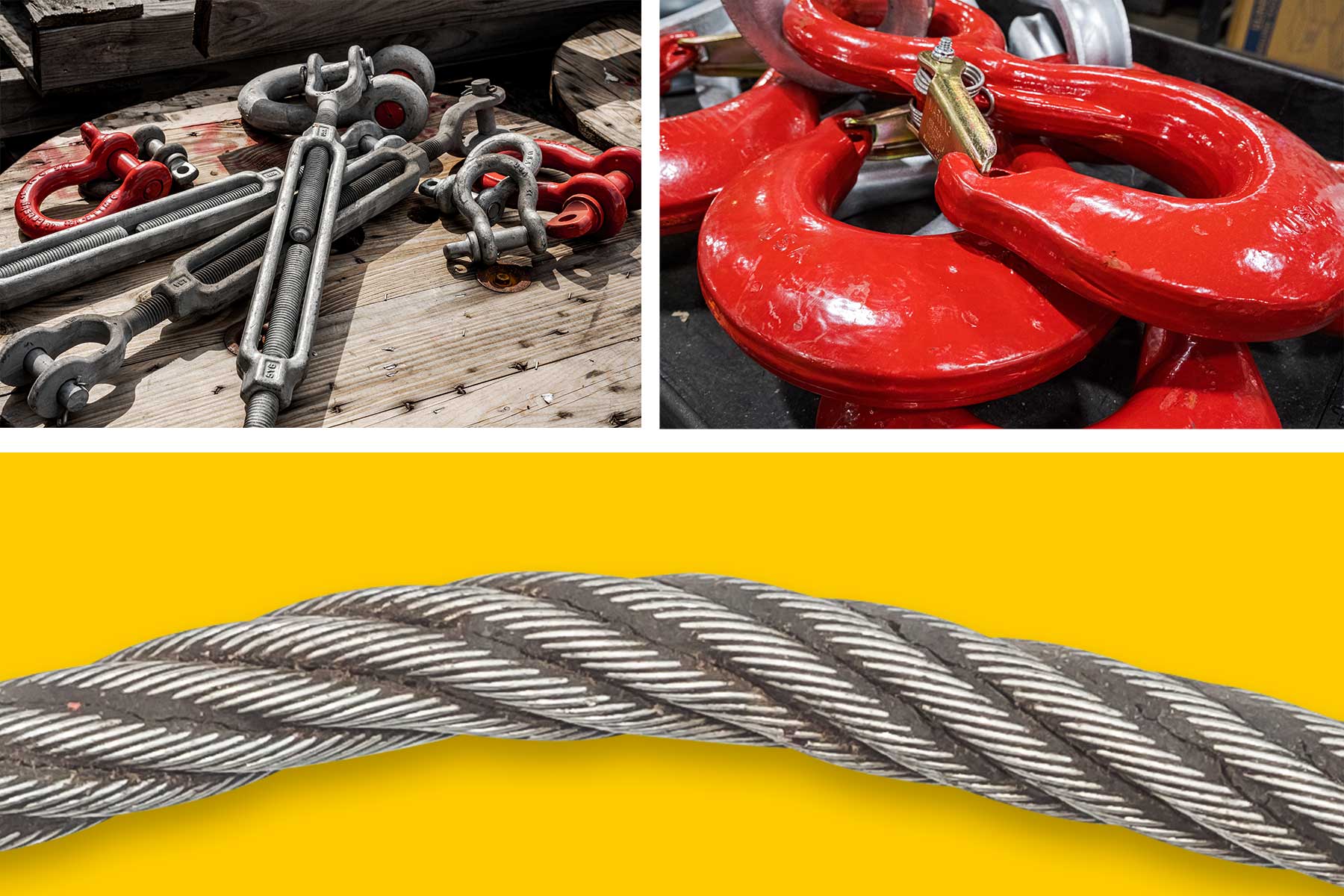

A Year in Review: The 10 Best Lifting and Rigging Articles of 2024

As the year comes to an end, and we begin planning out articles for 2025, we’ve compiled a list of our 10 best articles from 2024.

2024 was a wild and exciting time for lifting and rigging. Companies in our industry had to adjust in many ways: addressing labor shortages, embracing new technological advancements, and adjusting to rising inflation were some of the major ones.

As the year comes to an end, and we begin planning out articles for 2025, we’ve compiled a list of our 10 best articles from 2024. This list is by no means a power ranking, but a collection of some of the most popular articles and some of our personal favorites.

1. How to Advance Your Career in Lifting and Rigging

Tied to our annual Global Lifting Awareness Day (GLAD) campaign, this year’s topic focused on how lifting and rigging professionals can advance their careers.

While a career in lifting and rigging is incredibly diverse, important, and rewarding, we as an industry rarely get together to discuss our roles and how people can advance in them.

Organizations are not only looking for the next generation of Riggers – they are also looking for the next generation of Accountants, Engineers, Marketers, Human Resource Specialists, IT professionals, Safety Inspectors, and Trainers.

While some people have a preconceived notion of a career in lifting, there are many opportunities and career paths to go down, and it’s never too late to advance your career, regardless of your experience level or starting position.

Based on our special GLAD Safety Factor podcast episode, this article is all about how leveraging training opportunities and embracing technological advancements is paramount to expanding your career.

This is an especially great read for younger professionals, who may not understand just how many opportunities exist for them in lifting and rigging.

2. How to Safely Work in Confined Spaces: Key OSHA Standards and Best Practices

This was the first year we released articles discussing confined spaces.

With limited oxygen, limited entry and exit points, and a higher chance of encountering toxic chemicals and gases, a confined space is one of the most challenging and dangerous environments a company can place a worker.

This article not only covers the required training for confined space, but it also explains several important OSHA standards and general best practice tips, such as testing air quality and proper personal protective equipment (PPE).

3. OSHA, ASME, and ANSI: What They Do and How They’re Different

Whether you’re an executive, a seasoned crane operator, or an entry-level rigger, OSHA, ASME, and ANSI dictate much of the lifting and rigging industry, setting and enforcing standards.

On the surface, OSHA, ASME, and ANSI are similar: four-letter agencies wanting to advance worker safety and uphold industry standards. But there’s way more to it.

This article covers:

- The main functions of OSHA, ASME, and ANSI

- The history of each organization

- How each one affects the lifting and rigging industry

- How are OSHA, ASME, and ANSI different?

- How to keep your organization OSHA, ASME, and ANSI compliant

4. Why Should a Third-Party Inspect Your Warehouse Racks?

Right now, during the holidays, it’s peak season for warehouse and distribution centers in the United States.

Once the dust settles from peak season, are you ready to schedule a third-party rack inspection?

For many, their in-house safety department is more than capable of performing a rack inspection. But recently, the industry is moving towards third-party rack inspections being the standard.

Inspecting warehouse racks is an intricate, detailed, and important part of making your operations successful and safe, and having an unbiased, outside perspective will help make sure you’re getting the best inspection possible.

Mazzella has been a leader in providing OSHA compliant third-party rack inspections and our article looks to inform readers on what a third-party inspection system really looks like. We discuss:

- What are the Positives of a Third-Party Warehouse Inspection?

- What Does a Third-Party Rack Inspection Look Like?

- How Much Does a Third-Party Rack Inspection Cost?

- How Long Will a Third-Party Rack Inspection Take?

- Are You Ready for A Third-Party Rack Inspection?

5. Elebia Hooks in Steel Mills: What They Do and How They Deter Dangers

Steel mills have come a long way regarding employee safety and automation. A great example of this is the emergence of the Elebia automatic crane hook.

This lithium-ion battery-powered hook comes with a remote control, where operators can lift loads from over 450′ away. It also comes with an attached magnet, which eliminates the need for employees to manually line up bales or rings before closing them.

Historically used in ports and shipyards, The Elebia hooks’ advanced technology has made it a natural fit in any step of the steel mill production process. They can be used for lifting and rigging:

- Furnace components

- Offloading raw materials

- Tundish and scrap buckets

- Aluminum beams

- Heavy bags

With the steel industry moving towards no-touch processes, any professional in the industry can benefit from learning more about Elebia hooks.

6. How to Develop a Working at Height Rescue Plan

According to data from the Occupational Health and Safety Administration (OSHA), falls caused 37% of all construction deaths in 2021.

Even with great training and fall protection equipment, accidents can happen. This raises the question: Does your facility have a rescue plan in place?

Using and inspecting your fall protection gear is only half the battle. Building out a comprehensive working at height rescue plan, keeping it simple, and consistently reviewing it with your workers will prepare them for when the opportunity arises.

We not only discuss how to develop a working at height rescue plan, but we also discuss five tips to ensure your rescue plan runs properly, including:

- Documenting your rescue plan

- Rehearsing your plan

- Keeping your rescue plan simple

- Maintaining circulation

- Preparing to change your plan

This article is an essential read for anyone who works from height, especially those in the construction industry.

7. Mazzella & ITI Training: Their Similarities and Key Differences

Mazzella and Industrial Training International (ITI) have been partners for decades, providing organizations with top-tier lifting and rigging training across the country.

But many people, even our long-time customers, still don’t know the similarities and differences between our training programs. This article dives into:

- What Lifting Training is Available for Lifting Professionals?

- Is Lifting Training Required?

- What Is Covered in Mazzella’s Training Program?

- Who Is ITI?

- What Separates Mazzella and ITI Training?

- How Do Mazzella and ITI Work Together?

- Why Should You Invest in Mazzella and ITI Training?

This is article is a great read for anyone looking for a lifting and rigging training program for their workers.

8. What Is A Die Horse? Customizations, Pricing, and Best Applications

Die horses, also called industrial steel sawhorses, engineered sawhorses, and heavy-duty steel sawhorses, have a unique shape that gives maintenance workers an elevated surface to work on heavy loads. These simple yet effective tools have been a staple in die shops and manufacturing plants for generations.

Whether it’s your kitchen appliances, washing machine, furnace, workout equipment, car doors, or the tumbler sitting at your desk, heavy die stamping operations play a crucial role in people’s lives, and die horses are a crucial part of their manufacturing process.

To help you during your research process, our article will go over key questions, such as:

- What are Die Horses?

- How are Die Horses Used?

- Can You Customize a Die Horse?

- What Affects the Price of a Die Horse?

- What OSHA or ASME Standards Impact Die Horses?

- What are the Dangers of Homemade Die Horses?

- Are Die Horses a Good Fit at Your Facility?

This article is a great read for anyone involved in die-stamping operations or heavy-duty manufacturing.

9. The 16 Biggest Myths in the Lifting and Rigging Industry

Whenever Mazzella’s trainers head to a facility or job site, they hear some variation of these sentences: “We’ve been doing it this way since the beginning. Why would we change it now?” “We can’t afford to adopt a new process. It would slow down our operations.”

Because of how much the industry has changed, plenty of myths still circulate. Most of these myths come from convenience. In the early years, there were no industry standards as comprehensive as the ones we have today.

We understand it can be hard to kick old habits, especially if your experienced coworkers are the ones perpetuating them. Whether it was learning the truth about the CE label, or removing wire ropes with minor kinks, we hope this article equipped you with knowledge that you can bring back to your job site.

Some of the most common myths were here are:

- You can use any chain for an overhead lift

- ‘Backing it Off’ Is Good Practice for Screwing a Shackle

- If ASME Standards Say ‘Should,’ You Can Ignore It Without Penalty

- The Red Thread On Web Slings is an Out of Service Gauge

- Trainers are Undercover Salespeople and OSHA Sticklers

This article is great for anyone in the lifting and rigging industry. Whether you’re a seasoned veteran, a newcomer, a trainer, or safety manager, it’s always good to understand what myths are out there in our industry.

10. The Difference Between C-Hooks and Coil Lifters: Which One’s Right for You?

Our first article of the year was a strong one.

In warehouses, factories, and manufacturing sites across the country, there’s a good chance you’ll find coil hooks (commonly called c-hooks) and coil lifters on site. With industries relying heavily on steel, a device is needed to lift and move steel rolls—sometimes weighing several tons—from one place to another.

With some coils weighing several tons, manual labor is out of the question. This means you’ll need a below-the-hook lifting device to get the job done.

While lifting professionals love how affordable, lightweight, and ergonomic some lifting slings are, their material makes them susceptible to damage in intense environments. The sharp edges on metal coils also increase the chance of wear and tear on lifting slings and wire ropes.

Mazzella has years of experience designing, manufacturing, and inspecting c-hooks and coil lifters for a wide range of industries. Our article examines:

- The Best Applications for C-Hooks and Coil Lifters?

- How c-hooks and coil lifters are different

- What affects their pricing

- What industries could benefit from using c-hooks and coil lifters

- How to pick the right model for your organization

This article has great information for various professionals in the steel processing industry, including Safety Managers, Maintenance Managers, and Storeroom Managers.

Looking Onward to 2025

While we’re happy with the articles we published in 2024, we’re even more excited for the ones we have in store for 2025. Whether you’ve been following us for years or discovered us last week, we’re thankful for every person who takes the time to read and watch our content.

If you haven’t already, subscribe to Mazzella’s Learning Center so you never miss a new piece of content.

At Mazzella, we take pride in our 70 years of industry expertise. When you have a problem, we have a talented team of in-house Engineers, Lifting Specialists, Inspectors, Trainers, Product Specialists, and Technicians who can help design and develop creative and compliant processes or solutions.

Need help with a big rigging project in 2025? Contact one of our specialists today.

Copyright 2024. Mazzella Companies.