Year in Review: The Best Lifting and Rigging Articles of 2023

What have you learned over the last year that will allow you to have safer working conditions in 2024? Here is a look back at some of the most popular lifting and rigging topics we covered in 2023 that can help you improve safety on the jobsite.

Coming in with the hope that challenges in the supply chain had been resolved, 2023 was a year of adjusting to higher costs of production and finding quality employees to keep up with market demand.

While looking forward to 2024 with optimism, we’ve compiled a list of the top lifting and rigging articles we published this year. These articles could help you better understand risk in your business and discover ways you can improve the safety and efficiency of your operations by:

- Learning how to start an in-house safety program

- Choosing the correct clamp for your lifting application

- Knowing what to expect from a Working at Height Risk Assessment (WHRA)

- Learning what a self-closing hook does to improve jobsite safety

- Understanding terms, structures and systems related to tower cranes

- Learning how technology is being incorporated in crane operator training

- Understanding the terms used in the design of below-the-hook lifting devices

- Knowing what to expect from a composite lifting beam

- Figuring out when you need a warehouse racking inspection

- Learning what the BlokCam does to make crane operations safer

How Do You Start an In-House Safety Program?

“One machine can do the work of fifty ordinary men. No machine can do the work of one extraordinary man.”

The words of American writer/philosopher Elbert Hubbard easily translate to the importance of safety while conducting overhead lifts. With safety being a main concern of companies around the world, technological advances have made it easier to protect workers.

According to OSHA Publication 2056, there are nearly 6,000 workplace fatalities in the United States and 50,000 deaths due to workplace-related illnesses each year. Also, there are 5.7 million non-fatal workplace injuries, and those health issues alone cost U.S. businesses over $125 billion annually.

Developing an in-house safety program is one way to prevent serious injuries / deaths on the jobsite.

In this article, we’ll answer the following questions about creating an in-house safety program, including:

- Why do you need an in-house safety program?

- What are the requirements for a safety program?

- How can you build your in-house safety program?

- How can you win over the employees out in the field?

- What advice should you follow when starting your own safety program?

How To Choose the Correct Clamp for Your Lifting Application?

Do you need a new below-the-hook lifting device and think a clamp could be the right fit? When it comes to lifting clamps, there are plenty of options. However, when choosing a clamp, how do you know you’re picking the correct one for your lifting applications?

To answer this question properly, we reached out to engineering manager Dale Kelly of Caldwell/J.C. Renfroe Lifting Solutions in Rockford, Illinois to help outline what you need to know before choosing a clamp.

In this article, we’ll look at the factors you need to consider when choosing a clamp for your overhead lifts, including:

- Hardness of the metal

- How you plan on lifting with a clamp

- What kind of jaw opening is needed for your application

- The environment where the clamp will be used

- Confirmation upon receipt of the clamp

What Can You Expect from a Working at Height Risk Assessment?

“What can I expect from a Working at Height Risk Assessment at my facility?”

This is a question Mazzella Fall Protection Specialists hear from customers all the time, and the answer is lengthy, but simple at the same time. We’re going to come in and look at your facility, talk with you and your team and begin to understand what your employees do at height. Also, we’ll identify what height hazards they might be exposed to. This will help with the creation of a roadmap for your compliance with industry fall protection standards set forth by the Occupational Safety and Health Administration (OSHA). That means Fall Protection Specialists are going to:

- Tour your facility

- Ask key employees questions about how you do what you do

- Review any existing fall restraint or fall arrest systems for compliance

- Inspections

- Training

By taking these steps, you’ll have a roadmap to compliance for your facility, and good Fall Protection Specialists won’t stop there. If they notice areas of concern, they’re going to mention them. Then, they can write a report that spells out those points of concern and what can be done to make you compliant.

You want to get the most value for your money when obtaining quotes for a fall protection solution. When getting an accurate quote, it is important to understand your building’s:

- Work done at height

- Space

- Structure

- Obstacles

- Accurate measurements

All of these factors will be considered during a Working at Height Risk Assessment. In this article, you will learn what information is needed to create an accurate assessment of your facility.

What’s a Self-Closing Hook, & How Does It Improve Jobsite Safety?

“It takes leadership to improve safety.”

When racing legend Jackie Stewart coined this phrase, he wasn’t referencing overhead lifting and rigging. However, many companies, including Gunnebo Industries, a Crosby Group Company, and Columbus McKinnon (CM) followed the same mindset and developed the self-closing hook to improve safety in the construction industry.

Also known as a self-locking hook, safety hook, or positive-locking hook, these devices are hooks with latches that are designed to close under their own power. When you put a load on these hooks, they literally snap shut on their own, and that helps eliminate major safety concerns on the jobsite.

Due to their design principles, these hooks cannot open while under load, and that’s why it’s called a safety hook in some markets.

These hooks come in many types, including:

In this article, you’ll learn the answers to the following questions:

- Why was the self-closing hook created?

- What makes a self-closing hook different from other hooks?

- Why would you use a self-closing hook?

- Are there disadvantages to using a self-closing hook?

- Where have self-closing hooks been utilized in the field?

Tower Cranes: Common Terms, Structures, & Systems You Should Know

“Knowledge is power. Information is liberating. Education is the premise of progress, in every society, in every family.”

Former United Nations Secretary-General Kofi Annan’s words apply to just about every pursuit. Knowledge can be the difference between making it home safely and suffering a catastrophic injury / death. That is especially true when working with tower cranes. Not being educated could do irreparable harm to you, your family and your coworkers.

Educating yourself on the basics of construction cranes, specifically tower cranes, is a great way to jumpstart learning.

In this article, you will learn about:

- Basic terms associated with tower cranes

- Types of tower cranes

- Equipment used for load positioning

- Components and structures for tower cranes

How Is ITI Incorporating Technology into Crane Operator Training?

“Tell me, and I forget. Teach me, and I may remember. Involve me, and I learn.”

Industrial Training International, Inc. (ITI) has taken the words of Benjamin Franklin to heart, especially with crane operation. To help educate the next generation of crane operators, ITI has evolved its courses to include virtual training. This is not meant to be a replacement for real-world training, but more of a precursor to real-world exposure.

In this episode of the Safety Factor podcast, Andrew Houser, ITI’s Chief Product Officer and Senior Vice President of Simulated and Online Learning, and Adam Franz, Mazzella’s National Sales Manager, talk about some of the latest technological advancements in industrial training.

During this article, we’ll answer the following questions:

- How are virtual reality and augmented reality being used to improve industrial training for safety purposes?

- Is this training geared toward younger generations of workers?

- What’s it like being trained on the simulator?

- How does the VR training compare to real-world training on actual equipment?

- What might operators experience in simulator training?

- Are certifications required to go from simulator training to real crane training?

- Where is crane simulator training being used?

ASME BTH-1: Common Terms Used in Lifting Device Design

“Design is the method of putting form and content together.”

American designer Paul Rand’s words may not have been intended for the lifting and rigging industry, but they translate well. That is especially true when it comes to designing below-the-hook lifting devices, as it is both art and science.

Often, we hear the question: “Why would I waste time and money ordering a custom-engineered below-the-hook lifting device when I have an in-house engineer who could design and create one?”

While in-house engineers may have the mechanical skills and knowledge to make a device, they may not be familiar with the latest design standards or have access to proof-testing equipment to make sure all design factors are considered.

Designing compliant lifters is so complex that they actually have their own standard, ASME BTH-1 Design of Below-The-Hook Lifting Devices. This standard outlines everything that needs to be done for a below-the-hook lifting device to be compliant.

Educating yourself on the basics of below-the-hook lifting devices is a great way to jumpstart learning, as well as help save time and money when meeting with a third-party manufacturer. The more you know going into design meetings, the easier the process should be.

In this article, you will learn about:

- Basic terms associated with below-the-hook lifting devices

- Definitions for structural design

- Terms for mechanical design

- Definitions for electrical design

- Terms for lifting magnet design

What is Caldwell’s Dura-Lite™ Composite Lifting Beam?

“It’s not the size of the dog in the fight. It’s the size of the fight in the dog.”

This well-known phrase attributed to Mark Twain applies to many different fields. They describe a product Caldwell Lifting Solutions in Rockford, Illinois created: the Dura-Lite™ composite lifting beam.

Despite weighing a fraction of what its steel lifting beam or spreader bar counterparts do, the composite lifting beam could lift a half-ton load, or something as heavy as a:

- Grand piano

- Baby elephant

- Pile of more than 200 bricks

Dan Mongan, Caldwell’s senior sales engineer, explained to us the pros and cons, real-world applications and why you might want to choose composite over a metal beam.

In this article, you will learn the answers to the following questions:

- What is the Dura-Lite™ Lifting Beam made from?

- What are the advantages of using a composite lifting beam?

- Is the Dura-Lite™ composite beam as strong as steel?

- What are the disadvantages of using a composite lifting beam?

- Are there real-world examples of companies using composite lifting beams?

- Are composite beams the future of lifting?

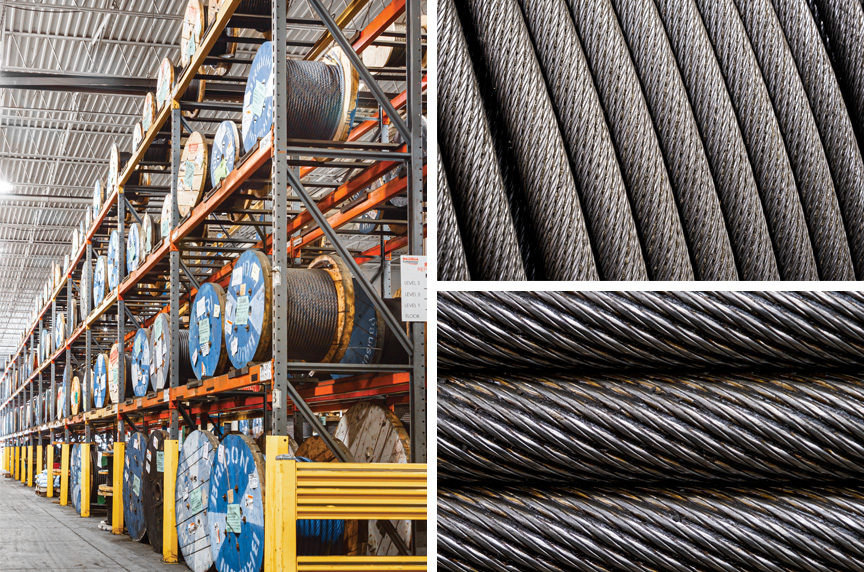

When & Why Would You Need a Warehouse Racking Inspection?

Warehouse rack inspections are not mandated by OSHA. However, they are recommended, and with good reason, as failing to do so could have disastrous consequences.

There are countless viral videos showing what happens to racking systems when struck by forklifts or overloaded with product. These structures can collapse, often causing a domino effect that damages / destroys millions of dollars of products.

Most importantly, should a completely preventable racking failure occur, people could experience severe injury or even death.

In the United States, the law stipulates that company management is responsible for providing a safe workplace for their employees. Putting workers at risk of injury can expose employers to serious liability in the event of an accident.

By controlling or eliminating hazards in the workplace, you help reduce the risk of an accident. Think about how quickly the costs of a workplace accident or fatality can add up, including:

- Lost wages

- Workers’ compensation

- Low employee morale

- Decrease in productivity

- Workforce shortages

- Potential legal fees and OSHA fines

In this article, we’ll answer the following questions:

- Why are racking inspections becoming more common?

- What is examined during a rack inspection?

- When do racking systems need to be inspected?

- What kind of inspection reports will warehouse managers receive?

- What does a racking inspection cost?

What Is the BlokCam, and How Does It Make Lifts Safer?

“Seeing is believing, and believing is knowing. Knowing beats unknowing and the unknown.”

Author Philip Roth wasn’t addressing the lifting and rigging industry with this quote, but his words translate well to technologies being developed. Particularly, his words accurately could describe one of Crosby’s newest products, the BlokCam System.

This new camera system is designed to improve safety on the jobsite. It allows the operator to visually and audibly monitor a load during a lift in situations that previously would’ve been impossible. Being able to see the load during a lift will help create safer work environments for everyone onsite.

In this article, we’ll answer the following questions:

- What is the BlokCam Camera System?

- How does the BlokCam Camera System work?

- What are the key benefits to using the BlokCam Camera System?

- What are the different models of the BlokCam Camera System?

How Can Mazzella Help You as You Look Forward to 2024?

While 2023 provided all of us with challenges as demands on production continued to grow, we have seen companies become innovative in their product design and creation.

This innovation helped develop better lifting and rigging solutions that will:

- Extend the life of your rigging equipment

- Improve safety for your overhead lifts

- Make sure you get the proper equipment ordered and installed

- Create safer work while at height

- Lead to investing in yourself and your career

At Mazzella, we pride ourselves on being able to help you improve the safety and efficiency of your businesses. When you have a problem, we have a talented team of Engineers, Lifting Specialists, Product Specialists, and Technicians who can help design and develop creative and compliant processes or solutions.

If you’re looking for an experienced and trustworthy partner as you move forward into 2024, we’d appreciate the opportunity to provide a quote or consultation on your next overhead lifting or material-handling project. Contact us to discuss your next project!

From all of us at Mazzella, we wish you and your employees Happy Holidays and continued health, safety, and success in 2024!

Copyright 2023. Mazzella Companies.