What Are Tower Crane Personnel Responsibilities, per ASME B30.3?

What are the responsibilities of tower crane personnel during an overhead lift? This section of the ASME B30.3 Tower Cranes standard outlines everything a tower crane operator needs to do during an overhead lift.

The success of a lift using a tower crane is not solely dependent on the crane operator or their signalperson.

There are many different roles on a construction site when a tower crane is in use, and those responsibilities are spelled out by the American Society of Mechanical Engineers in the ASME B30.3 Tower Cranes standard. In that standard, they outline responsibilities for the tower crane’s:

- Owner / User

- Site Supervisor / Lift Director

- Rigger

- Signalperson

While making safe and successful lifts is the main goal of any overhead pick, there are many other tasks that tower crane personnel must perform in order to conduct their lifts safely and successfully, as defined by industry standards.

In this article, we’ll discuss what ASME lists as the responsibilities of tower crane personnel before, during, and after an overhead lift.

What Are the Responsibilities of a Tower Crane Owner / User?

In some cases, the tower crane owner and user may be the same person.

If this is the case, that person would be responsible for the safe execution of many duties. With situations where the owner and user are separate people, the user may lease or rent the crane from the owner without supervisory, operational, maintenance, support personnel, or services from the owner.

Tower Crane Owner Responsibilities

According to ASME B30.3 Tower Cranes, a tower crane owner’s responsibilities shall include providing a crane:

- That meets the requirements of Chapter 3-1* of the appropriate edition of this Volume

- Has all necessary components, specified by the manufacturer, that meet the user’s requested configuration and capacity

- Comes with all applicable load rating charts and diagrams

- With additional technical information pertaining to the crane, necessary for crane operation, when requested by the crane user

*Chapter 3-1 outlines requirements for the erection, climbing, dismantling, characteristics, and construction of tower cranes.

Additionally, a tower crane owner’s responsibilities shall include:

- Providing field erection, dismantling, operation, maintenance information, warning decals, and placards, installed as prescribed by the crane manufacturer and regulatory bodies

- Establishing an inspection, testing, and maintenance program in accordance with Chapter 3-2* and informing the crane user of the requirements of this program

- Using personnel that meet the requirements for a designated person for the purposes of maintenance, repair, transport, erection, climbing, and dismantling

- Using personnel that meet the requirements of a qualified or designated person where required within the provisions of this Volume

*Chapter 3-2 outlines the requirements for inspecting, testing and maintaining a tower crane.

Tower Crane User’s Responsibilities

User’s responsibilities shall include ensuring:

- Compliance with the requirements of this Volume, manufacturer’s requirements, and those regulations applicable at the work site

- Using supervisors for crane activities that meet the requirements for a qualified person

- The crane is in proper operating condition prior to initial use at the work site, by:

- Verification that the owner has provided documentation that the crane meets the requirements of para. 3-2.1.1*

- Verification that a frequent inspection has been performed as defined in para. 3-2.1.3**

- Verification that the crane has the necessary lifting capacity to perform the proposed lifting operations in the planned configuration

- Using operators that meet the requirements of paras. 3-3.1.1 and 3-3.1.2*** and are qualified to perform the tasks that are required with the crane that they are assigned to operate

- The assigned operator has been notified of adjustments or repairs that have not yet been completed, prior to commencing crane operations

- Using personnel that meet the requirements for inspections in Section 3-2.1*

- Using personnel that meet the requirements of a designated person for the purposes of maintenance, repair, transport, erection, climbing, and dismantling

- All personnel involved in maintenance, repair, transport, erection, climbing, dismantling, and inspection are aware of their responsibilities, assigned duties, and associated hazards

- The inspection, testing, and maintenance programs specified by the crane owner are followed

- Cranes are not climbed when wind speed at the top of the crane exceeds 20 mph (9 m/s) or as recommended by the manufacturer or a qualified person

- The crane operator is present during climbing operations

- Climbing operations are not commenced until all support provisions required at the new support level are in place and as specified by a qualified person

- Night operation lighting is adequate to illuminate the working areas while not interfering with the view of the operator

*Sections 3-2.1 and 3-2.1.1 outline the general inspection requirements for tower cranes

**Section 3-2.1.3 outlines the frequent inspection requirements for tower cranes

***Sections 3-3.1.1 and 3-3.1.2 outline the qualifications for tower crane operators

What Are the Responsibilities of a Tower Crane Site Supervisor and Lift Director?

At some work sites, the site supervisor and lift director may be the same person.

If that is the case, their responsibilities shall include ensuring the following:

- The crane meets the requirements of Chapter 3-2* prior to initial use.

- Determining if additional regulations are applicable to the crane operations.

- A qualified person is designated as the lift director.

- Crane operations are coordinated with other jobsite activities that will be affected by or will affect lift operations.

- The area for the crane is adequately prepared. The preparation includes, but is not limited to, the following:

- Access roads for the crane components and associated equipment

- Sufficient room to erect and dismantle the crane

- A support system that is suitable for the crane with respect to levelness, surface conditions, support capability, proximity to power lines, excavations, slopes, underground utilities, subsurface construction, and obstructions to crane operation

- Restrict unauthorized access to the hazardous working areas of the crane

- Work involving the erection, dismantling, climbing, and reconfiguring of a crane is performed by a designated person.

- Work involving the erection, dismantling, climbing, and reconfiguring of a crane is supervised by a qualified person.

- Crane operators meet the requirements of para. 3-3.1.2**.

- Conditions which may adversely affect crane operations are addressed. Such conditions include, but are not limited to, the following:

- Poor support conditions

- Wind velocity or gusting winds

- Rain

- Fog

- Cold

- Artificial lighting

- Determining if any energized conductors in the proximity of the site create a hazard and allowing crane operation near electric power lines only when the requirements of para. 3-3.4.3*** have been met.

- Allowing special lifting operations only when equipment and procedures required by this Volume, the crane manufacturer, or a qualified person are employed. Such operations include, but are not limited to, the following:

- Multiple crane lifts

- Lifting personnel

- Rail traveling under load

- Work performed by the rigging crew is supervised by a qualified person.

- Crane maintenance is performed by a designated person.

*Chapter 3-2 outlines the requirements for inspecting, testing and maintaining a tower crane.

**Section 3-3.1.2 outlines the qualifications for tower crane operators

***Paragraph 3-3.4.3 outlines the requirements for crane operation in the vicinity of electric power lines.

Lift Director’s Responsibilities

If the site supervisor and lift director are different people, the lift director’s responsibilities shall include:

- Being present during lifting operations.

- Stopping crane operations if alerted to an unsafe condition affecting those operations.

- Ensuring that the preparation of the area needed to support crane operations has been completed before crane operations commence.

- Verifying that unauthorized access to any hazardous working areas of the crane is restricted.

- Ensuring that personnel involved in crane operations understand their responsibilities, assigned duties, and the associated hazards.

- Addressing safety concerns raised by the operator or other personnel, and being responsible if he/she decides to overrule those concerns and directs crane operations to continue. In all cases, the manufacturer’s criteria for safe operation and the requirements of this Volume shall be met.

- Appointing the signalperson, if required, that meets the requirements of Section 3-3.3*, and conveying that information to the crane operator.

- Allowing crane operation near electric power lines only when the requirements of para. 3-3.4.3** and any additional requirements determined by the site supervisor have been met.

- Ensuring precautions are implemented when hazards associated with special lifting operations are present. Such operations include, but are not limited to, the following:

- Multiple crane lifts

- Lifting personnel

- Rail travel under load operations

- Tower cranes operating on barges

- Out-of-service conditions

- Ensuring that the applicable requirements of ASME B30.23 Personnel Lifting Systems are met when lifting personnel.

- Informing the crane operator of the weight of loads to be lifted, as well as the lifting, moving, and placing locations for these loads, and obtaining the operator’s verification that this weight does not exceed the crane’s rated capacity.

- Ensuring that the crane load rigging is performed by a designated person.

- Ensuring that the load is properly rigged and balanced before it is lifted more than a few inches.

*Section 3-3.3 provides clarity on the signals needing to be used in the operation of a tower crane.

**Paragraph 3-3.4.3 outlines the requirements for crane operation in the vicinity of electric power lines.

What Are the Responsibilities of a Tower Crane Rigger?

A rigger is tasked with connecting and disconnecting a load to a crane.

Riggers assigned to a load handling activity shall at a minimum be responsible for:

- Ensuring the weight of the load and its approximate center of gravity have been obtained, provided, or calculated

- Selecting the proper rigging equipment, inspecting it, and complying with the applicable operating practices according to the criteria of the applicable ASME volume (i.e., B30.9 Slings, B30.10 Hooks, B30.20 Below-the-Hook Lifting Devices, B30.23 Personnel Lifting Systems, B30.26 Rigging Hardware)

- Ensuring the rated load of the rigging equipment as selected and configured is sufficient for the load to be handled, based on the number of legs, hitch configuration, and effects of angles

- Properly attaching the rigging equipment to the hook, shackle, or other load handling device

- Ensuring that rigging equipment is adequately protected from abrasion, cutting, or other damage during load handling activities

- Rigging the load in a manner to ensure balance and stability during the load handling activity

- Knowing and understanding the applicable signals for the equipment in use

- Installing and using a tag line(s) when additional load control is required

What Are the Responsibilities of a Tower Crane Signalperson?

A signalperson is on site to facilitate communication with the crane operator.

The signalperson assigned to a load handling activity shall at a minimum be responsible for:

- Identifying themselves as the signalperson to the operator(s) before commencing a load handling activity

- Confirming with the operator the method of communication and the associated signals that are to be used during the load handling activity

- Ensuring that standard, discernible hand or voice signals provided to the operator are in accordance with paras. 3-3.3.4 and 3-3.3.5*

- Verifying that load handling activities are stopped if there is a need to give instructions to the operator, other than those provided by the established signal system

- Ensuring that telephones, radios, or other equipment intended for use as the primary signal system are tested prior to the load handling activity

- Ensuring that a form of communication is maintained with the operator during all load handling activities

- Ensuring that all directions given to the operator shall be given from the operator’s perspective (e.g., swing right)

- Ensuring that each series of voice signals contains three elements stated in the following order:

- Function and direction

- Distance and/or speed

- Function stop

- Ensuring that special signals (when needed) that are not covered by para. 3-3.3.6** do not conflict with standard signals

- Avoiding giving signal commands that would result in loads being lifted over personnel whenever possible

*Paragraphs 3-3.3.4 and 3-3.3.5 outline the standard hand and voice signals used in the operation of a tower crane.

**Paragraph 3-3.3.6 discusses the use of special signals in the operation of a tower crane.

What Can Mazzella Do to Help You Stay in Compliance with the ASME B30.3 Tower Cranes Standard?

If you need help getting in compliance with the ASME B30.3 Tower Cranes standard, Mazzella is here to help with all of your lifting and rigging needs. With our ready stock inventory, we offer all industries a variety of lifting and rigging devices.

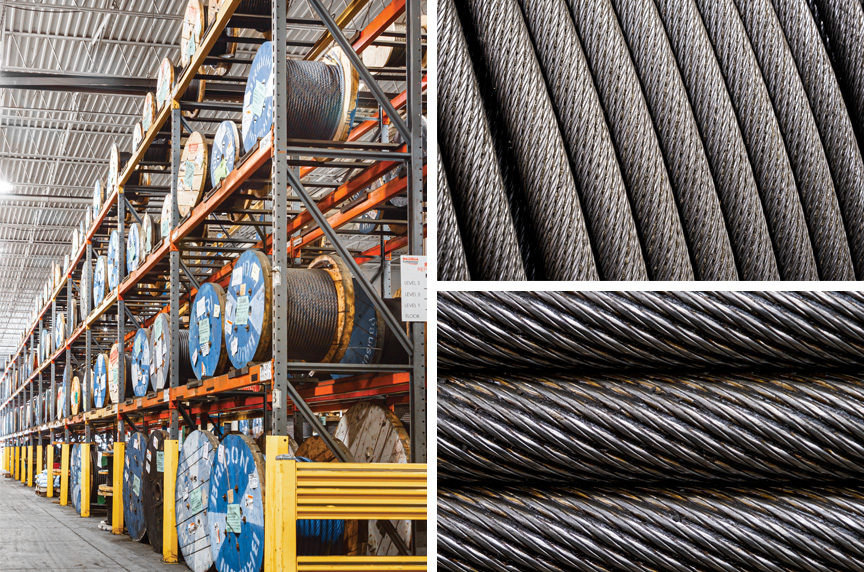

Crane Ropes

Mazzella is a one-stop-shop for high-performance crane ropes, or any kind of specialty ropes. Also, we have fittings and sockets that we can install in the field, and a large inventory of ropes in stock that allows us to help get you back up and running as quickly as possible.

We offer a new rope replacement off the same spooling truck and trailer used for inspections. If it’s a rope replacement, that’s something we can typically get on a truck and on the way the same day if the order is placed by 2 p.m. ET. If that happens, we can get the rope on the road and conduct the installation the next day.

Mazzella has one of the largest specialty rope inventories in the United States…ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies:

- In sizes from ¼” to 3” diameter and 9mm to 52mm diameter

- Domestic and Non-Domestic

- In stock and ready for same or next-day shipment from one of our many service centers

In addition to crane ropes installations and inspections, Mazzella has the capabilities to do button and OEM socket installations. We have technicians around the country who have been trained to do:

- Socket installs

- Perform crane rope inspections

Hardware

We offer one of the largest and most complete inventories of rigging and lifting products in the country from some of the largest manufacturers in the world. Some of the products we stock are:

- Shackles—all types, sizes, and finishes from ¼ ton to over 1,000 tons

- Hoist rings—standard and metric

- Eyebolts—forged, metric, and stainless steel

- Hooks—swivel, eye, choker, self-locking, and weld-on

- Master rings / links—all sizes, types and finishes

- Turnbuckles and swivels

Rigging Training

If you require a specific training course for OSHA (Occupational Safety and Health Administration) compliance for slings, hoists and / or rigging hardware, Mazzella can assist you in creating a safe and reliable workplace.

Our rigging training focuses on:

- Overhead cranes

- Below-the-hook lifters

- Lifting slings

- Rigging hardware

- Wire rope

All Mazzella trainers have been accredited by our company through training by a third party (Industrial Training International, Inc.), Mazzella Companies’ internal Train-the-Trainer program, and are trained on OSHA and ASME standards.

Also, we provide site assessments. The purpose of an assessment is to systematically observe and record your lifting and rigging procedures, equipment, and records. This is not an inspection, but rather, a general assessment by which opportunities for improvement may be identified.

Rigging Inspection Services

OSHA 1910.184, ASME B30.9 Slings, ASME B30.20 Below-the-Hook Lifting Devices, ASME B30.26 Rigging Hardware & ANSI Z359 require…

Periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions.

Our rigging inspectors are certified to ensure your products meet OSHA and ASME requirements. Also, we provide personal fall protection inspections and basic level non-destructive testing (NDT) inspections to support our visual inspections.

Call us at 800.362.4601 or click here if you need inspections for rigging hardware, training, or any of our other services.

Crane Ropes

One Brand of Rope Will Not Work on Every Machine!

Mazzella stocks a large inventory of high-performance wire ropes available for immediate delivery.

Copyright 2023. Mazzella Companies.