Description

SX

SX wear protection is designed to offer the highest cut and abrasion resistance protection to your rope. Manufactured with HMPE (High Modulus Polyethylene), the SX wear protection is a braided tubular structure offering 100% protection to the rope. The HMPE fiber is lightweight, floats and has excellent cut resistance. SX wear protection does not absorb water and can be splice-terminated into Cortland braided ropes.

Key benefits of SX wear protection:

- Superior wet and dry protection

- Lightweight

- Flexible

- Cut resistant

- HMPE fiber

- Low coefficient of friction

- UV resistant

- Easy to handle

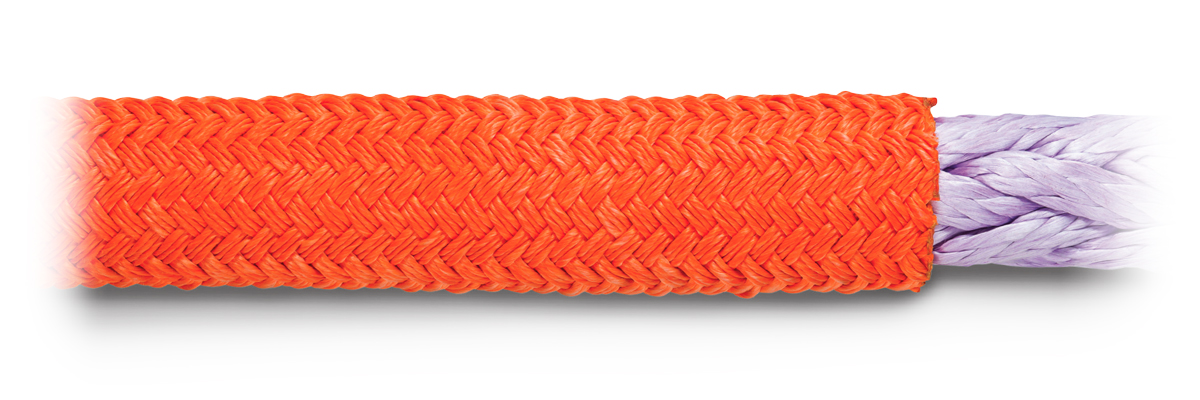

Cortland Cage

The Cortland Cage solution combines the lightweight, abrasion resistant, and non-water-absorbing properties of HMPE fiber in a braided cover sleeve. Cortland Cage can be secured in place by splice-termination or heavy duty whipping. The open braid pattern allows inspection of Plasma® 12×12 and reduces the total weight of the wear protection. Cortland Cage offers excellent cut and abrasion resistance of all braided wear protection. In addition a proprietary polyurethane coating provides added protection in challenging marine environments.

Key benefits of Cortland Cage:

- Extra protection against cutting and abrasion

- Open braid pattern allows inspection of rope

- Proprietary polyurethane coating

- Lightweight and floats

Click here to see specifications.

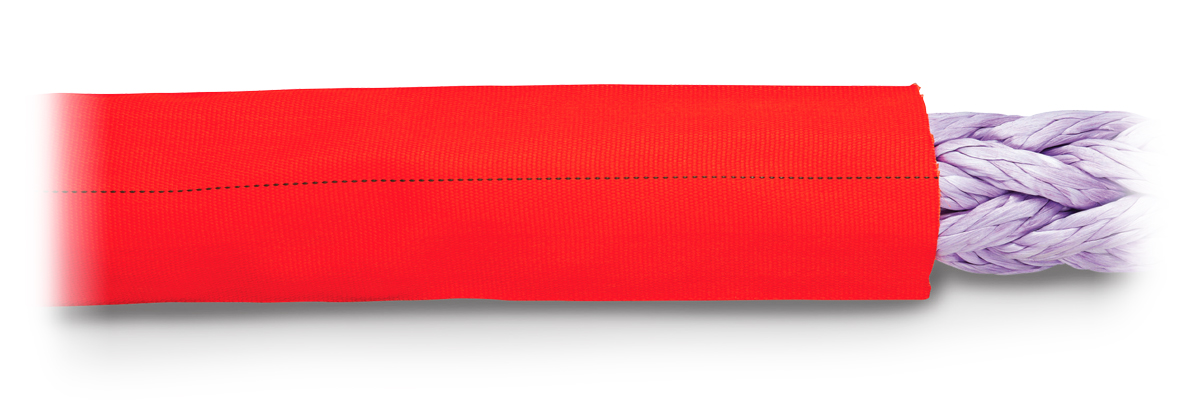

Asgard

Asgard wear protection is typically used for protection of lifting or mooring ropes and provides outstanding durability and resistance towards harsh operating conditions. The design features a strong, lightweight construction which is easy to install and retrofit on existing items. Asgard wear protection is designed according to a given diameter of the item to be protected and is provided in lengths according to client specifications.

Asgard wear protection is made from HMPE (High Modulus Polyethylene) and PNW (polyester and/or nylon) fibers in a woven, laminated and PUcoated construction and built in a layered design. The fibers utilized are the toughest of the traditional synthetic fibers. HMPE, for example, is used in personal armor products and PNW is used by the military for belts and webbing. Asgard wear protection can be delivered in a flat construction for protection of webbing, or in a circular construction, for use on mooring ropes for instance.

Asgard wear protection can be custom fabricated to other dimensions and configurations per customer requirements.

Key benefits of Asgard:

- Available with hook-and-clasp, or lace-on closures

- Custom fabricated to fit rope diameter and length requirements

Click here to see specifications.

DXC

The DXC wear protection is a tightly braided tubular polyester sleeve with proprietary marine polyurethane coating for use in extreme applications. Excellent choice for placement in the eye or body of sling; DXC sleeves can be fabricated to be free-floating or fixed in place. The DXC sleeve covers rope sling sizes from 1/4″ (6 mm) diameter through 4-1/4″ (104 mm) diameter. Other sizes and colors available upon request.

Click here to see specifications.

XT

XT wear protection is a tightly braided tubular polyester wear protection sleeve with proprietary heavy marine polyurethane coating for use in extreme applications. XT sleeves can be fabricated to be free-floating, or fixed in place. It is an excellent choice for eye terminations or selected area body placement, braid-spliced or seized in place. This wear protection option is not as flexible as SX or PNW.

Click here to see specifications.

PNW Tubular

PNW is a woven fiber material and is the most commonly used protection for abrasion. This wear protection is a permanent installation. PNW wear protection can be customized to meet the needs of any application. Standard colors are black or orange.

Click here to see specifications.

PNW with Hook-and- Clasp Securement

PNW is a woven fiber material and is the most commonly used protection for abrasion. PNW protection can be customized to meet the needs of any application. This is a removable or replaceable wear protection and is available in black or orange.

Click here to see specifications.