Overhead Cranes & Material Handling

-

Custom Engineered Cranes & Hoists

-

Patented Track Crane Systems

-

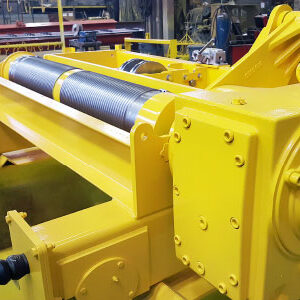

Custom Engineered and Built-Up Hoists

-

Gantry Cranes

-

Workstation Cranes

-

Jib Cranes

-

Monorail Cranes

-

Boat Transfer Lifts

-

Davit Cranes

-

Crane Runways

-

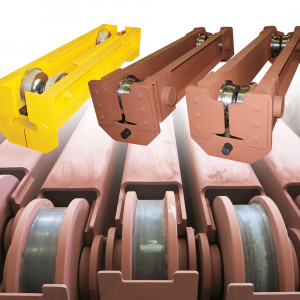

End Trucks

-

Crane Upgrades & Mods

-

Crane Controls

-

Remote Radio Controllers

-

Crane Electrification

-

Festoon Electrification

-

Crane, Trolley, & Dock Bumpers

We are a leading manufacturer of world-class overhead cranes with over 70 years of experience.

We engineer and build custom solutions ranging from light-duty, economical cranes up to large capacity, high-duty cycle cranes with welded plate-box girders. We provide all types of overhead crane systems, including bridge cranes, gantry cranes, workstation cranes, jib cranes, monorail cranes, and more!

We have on-staff engineering and computer-aided design (SolidWorks) capabilities to build customized indoor cranes and runway systems to a lifting capacity in excess of 150 tons. Our work is done in full compliance with CMAA, NEC, OSHA and ASME standards. We have extensive electrical / control engineering capabilities, as well as AWS certified welders (AWS D1.1 and D14.1).

Call us at 800.664.3380 or click here if you need to speak with one of our Crane Specialists!

Still Have Questions?

Connect with our specialist today! We will help you answer any questions you may have and assist you in completing your project.