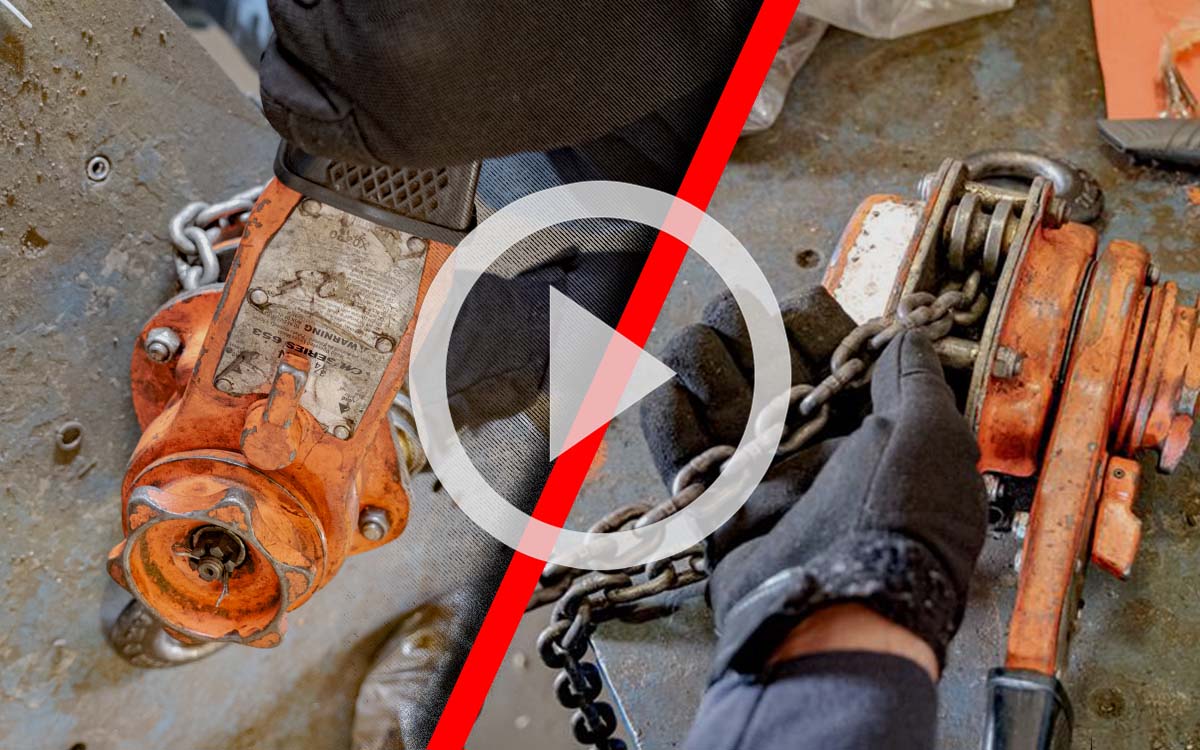

Rigging Equipment

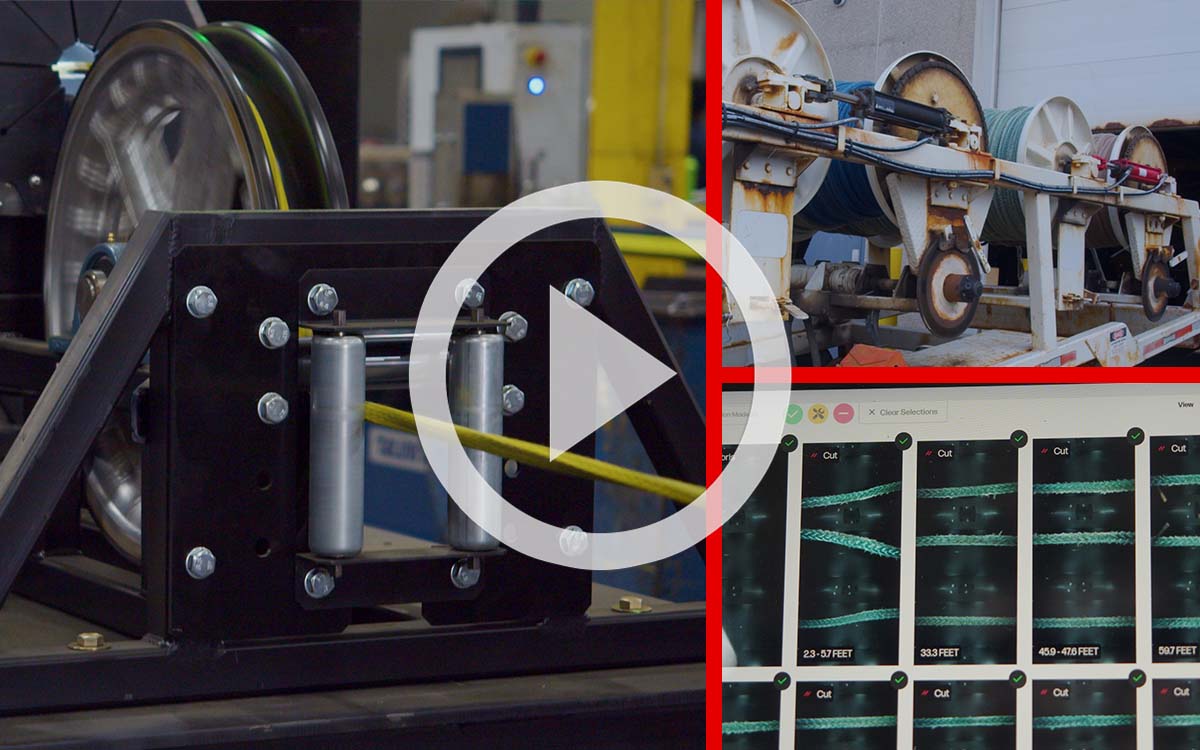

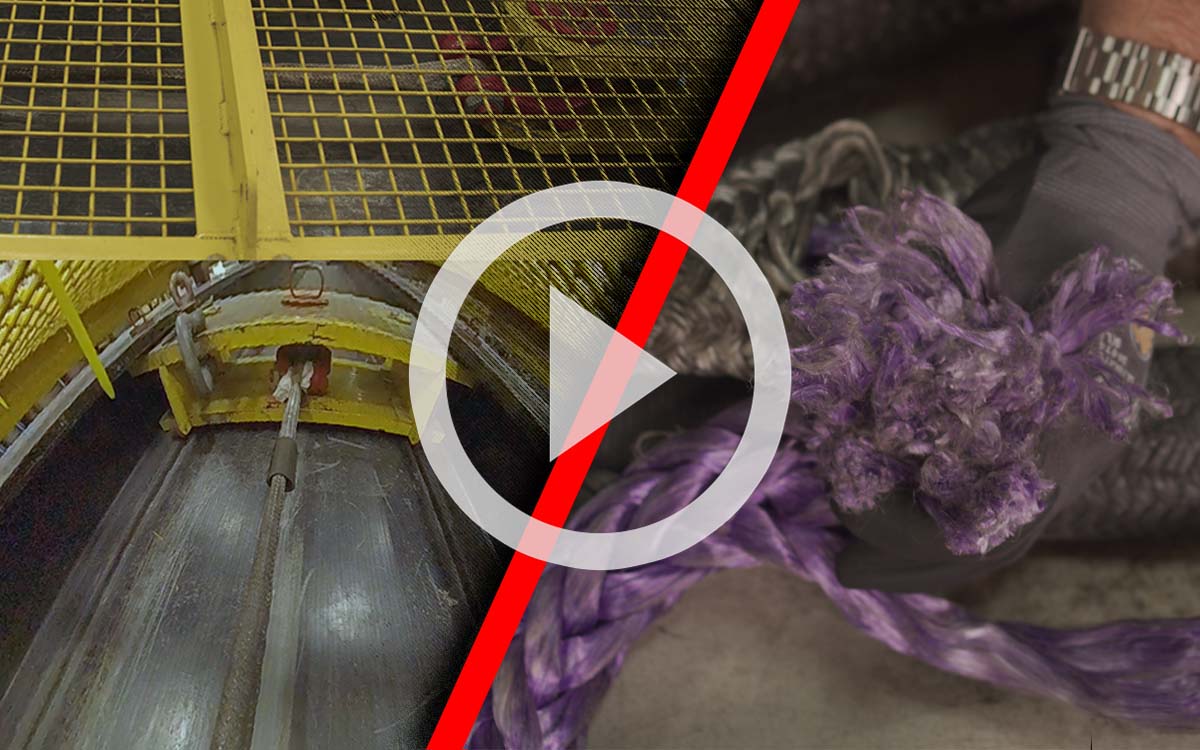

Rigging equipment includes products like lifting slings, wire rope slings, synthetic web and synthetic roundslings, alloy chain slings, synthetic rope slings, wire rope and high-performance crane ropes, and rigging hardware—including hooks, shackles, eye bolts, turnbuckles, and more.