Four Ways to Plan and Prepare for a Mazzella Third-Party Rigging Inspection (2026)

This article provides an overview of what you should know to prepare for a third-party rigging inspection.

Estimated reading time: 8 minutes

Need to schedule your next rigging inspection? Contact our team today!

Inspecting your rigging gear is one of the most important steps you can take to improve safety, reduce downtime, and stay compliant with OSHA and ASME standards.

However, lifting slings, rigging hardware, hooks, below-the-hook devices, and fall protection soft goods all have their own inspection frequencies, removal from service criteria, and documentation requirements. Compliance gaps often occur not because companies are negligent, but because managing large inventories of lifting gear can be overwhelming.

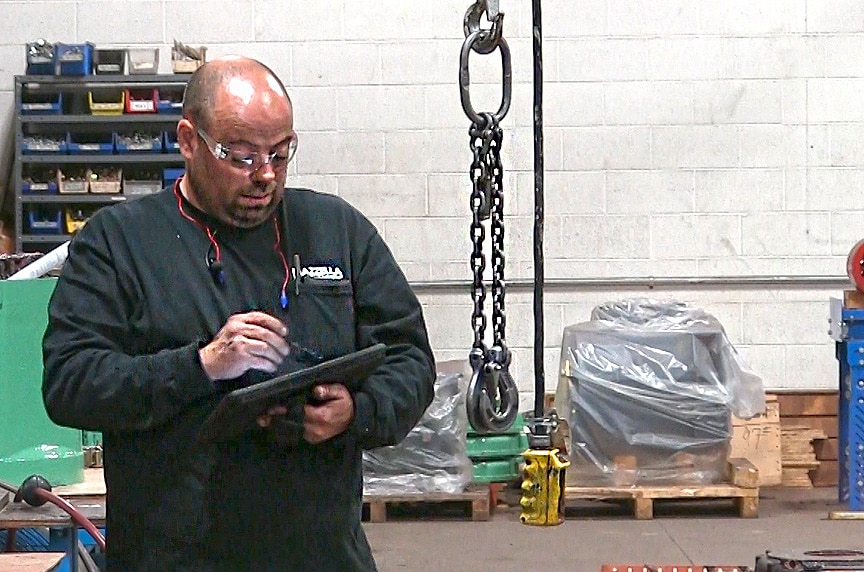

If you work at a large automotive plant or manufacturing facility, your workers are using hundreds of pieces of rigging equipment. You probably understand how much of a herculean effort it takes to keep rigging equipment compliant. That’s why companies rely on third-party rigging inspectors, like Mazzella, to enter their facility and give them an unbiased and thorough review of their equipment.

The more organized and informed you are before the inspectors arrive, the smoother the process will be. This article provides an overview of what you should know and how to prepare, based on the practices of Mazzella’s full-time, in-house rigging inspectors.

Table of contents

- What Standards Do Rigging Inspectors Reference?

- How Can You Prepare for Your Third-Party Rigging Inspection?

- Should You Consolidate Multiple Rigging Inspections?

- How Good Preparation on Inspection Day Saves You Money

- How Much Does a Rigging Inspection Cost?

- Why Mazzella Is a Trusted Rigging Inspection Partner

- Frequently Asked Questions about Rigging Inspections

What Standards Do Rigging Inspectors Reference?

The standards for lifting sling inspection are OSHA 1910.184 and ASME B30.9. Both of these standards offer inspection guidelines and they also provide criteria for removal from service. The employer has a responsibility to see that the slings in their facility are inspected according to these standards.

OSHA states that the employer has the responsibility to inspect and document lifting slings at a minimum of 12-month intervals. The employer is also required to maintain a record of the most recent thorough inspection, and failing to do so is one of the most common issues we see that can prevent a company from reaching full OSHA compliance.

The following standards are what our inspectors commonly reference during an inspection:

| OSHA 1910.184 | Slings |

| ASME B30.9 | Slings |

| ASME B30.10 | Hooks |

| ASME B30.16 | Overhead Hoists (Underhung) |

| ASME B30.20 | Below-the-Hook Lifting Devices |

| ASME B30.21 | Lever Hoists |

| ASME B30.26 | Rigging Hardware |

Additional Standards to Consider

Most facilities only need to comply with these federal and industry standards. However, some companies operate under additional internal guidelines, state-specific programs like MIOSHA or Cal/OSHA, or industry-specific rules such as those found in mining, maritime, or heavy manufacturing.

If your company uses standards beyond OSHA and ASME B30, the inspectors will need that information before the inspection begins so the scope can be clearly defined.

How Can You Prepare for Your Third-Party Rigging Inspection?

There are several ways your company can prepare for a rigging inspection.

Provide Previous Inspection Reports

It is helpful to share previous inspection reports with your inspector ahead of time. Past records provide insight into the type, quantity, and condition of your rigging gear. They can also highlight items that were flagged in earlier evaluations.

Provide an Inventory of Rigging Gear

Even if you don’t have prior documentation, it’s helpful to provide an approximate count of the items that need to be inspected. This allows the inspector to estimate the required labor, the number of inspectors needed, and the total time required.

Ensure Clear Access to Rigging Equipment

Accessibility is one of the leading factors that influence how long a rigging inspection takes. Before the inspectors arrive, make sure your rigging equipment is not buried in storage or scattered across multiple areas.

The goal is to create a clear, organized staging area where slings, hardware, and below-the-hook devices can be reviewed quickly and efficiently. When inspectors spend significant time searching for gear, moving equipment, or clearing space, the overall cost and total inspection time increase.

Ideally, all equipment that requires review should be placed in a designated area that is easy to access and free from obstruction. If your rigging gear is normally stored throughout the facility, assign someone ahead of time to gather and consolidate the items before the inspection begins.

Consider Your Work Environment and Site Requirements

Every facility has unique safety and access requirements that even inspectors must follow.

Some job sites require additional training before a contractor is allowed on-site. Others require specific protective equipment because of chemical baths, high temperatures, outdoor exposure, or work at extreme heights. If any of these situations apply to your facility, make sure the inspector knows beforehand so they can schedule the appropriate personnel and account for additional time.

Some facilities also require background checks or drug testing for outside service providers. These processes often take time to schedule and complete. Sharing these requirements early prevents delays and ensures inspectors can begin the job as planned.

If any of your lifting equipment requires special testing, such as magnetic particle testing or on-site proof testing, notify the inspection provider before they arrive. These services require additional planning and may involve special equipment or technicians.

Should You Consolidate Multiple Rigging Inspections?

Many facilities choose to have multiple categories of equipment inspected during the same visit. Lifting slings, rigging hardware, lever tools, below-the-hook devices, and personal fall protection can often be evaluated during a single trip.

Combining inspection categories is usually more economical than having inspectors return multiple times throughout the year. It also consolidates your compliance documentation, making it easier to track and review items during future audits.

How Good Preparation on Inspection Day Saves You Money

As we explained in previous articles, good preparation makes the inspection not only more productive, but it can also save you money.

Inspection cost and scheduling depend heavily on the size and diversity of your rigging inventory. A facility with hundreds of slings, multiple below-the-hook devices, and a full assortment of hardware will require more time and personnel than a facility with fewer items. To keep inspection time and cost down:

- Provide inspectors with an accurate equipment list during the “front-load” discovery phase

- Clear out old, unused equipment to speed up inspection process

- If a building closes, operations shift, or equipment moves, let the inspection team know in advance.

How Much Does a Rigging Inspection Cost?

As mentioned, the cost of a rigging inspection depends on several factors, including proper preparation from your end.

Mazzella offers inspections on a port-to-port basis. This means pricing includes the time it takes for our inspectors to leave the nearest office, travel to your facility, complete the inspection, and return.

- Half-Day (four hours): $480 – $600

- Full-Day (eight hours): $960 – $1,200

This ensures all travel and inspection time is bundled into one transparent rate.

Why Mazzella Is a Trusted Rigging Inspection Partner

Over the years, Mazzella has built one of the most comprehensive rigging inspection programs in the country.

We employ a team of full-time, qualified inspectors who focus exclusively on lifting and rigging equipment, below-the-hook devices, and fall protection. Their experience spans decades in manufacturing, steelmaking, construction, energy, ports, and other demanding applications.

Furthermore, our inspectors are certified by our partners at Industrial Training International (ITI), which means they meet all requirements to perform inspections in accordance with OSHA and ASME standards.

Depending on your needs, Mazzella can also set up a proactive inspection program to reach out to you monthly, quarterly, or annually depending on the agreement you have in place. This helps to take a lot of the guesswork out of when the inspections will occur, and also helps take some of the responsibility off of your shoulders to remember to schedule your inspections.

Our team also provide digital reporting of all inspection records that you can show to an OSHA inspector.

All of these inspections are on top of our wide range of service offerings. Contact Mazzella today to request a quote for your next rigging inspection.

Frequently Asked Questions about Rigging Inspections

Copyright 2025. Mazzella Companies.