Should You Repair or Replace Your Below-the-Hook Lifting Device?

Learn the major factors that determine whether your BTH device is repairable, what drives costs, how lifecycle affects your decision, and what to know before you send anything in.

Watch the full video on the Lifting & Rigging Channel:

When a below-the-hook (BTH) lifting device fails or stops operating the way it should, most people immediately ask the same question: “Should we repair it or replace it?”

The answer is not always obvious. And making the wrong choice can cost you money, put operators at risk, or delay your production schedule. Purchasing an engineered lifting device is a big decision, and you want to ensure you’re making the right choices to get the most out of your investment.

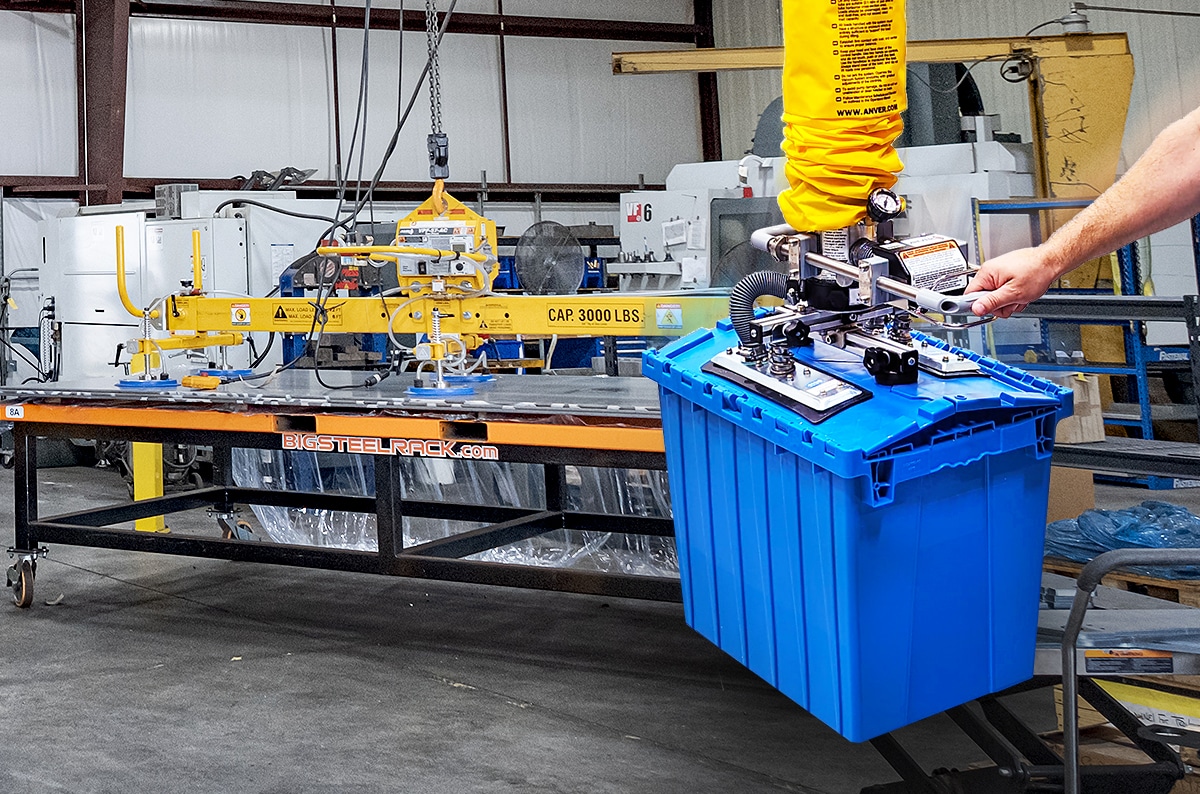

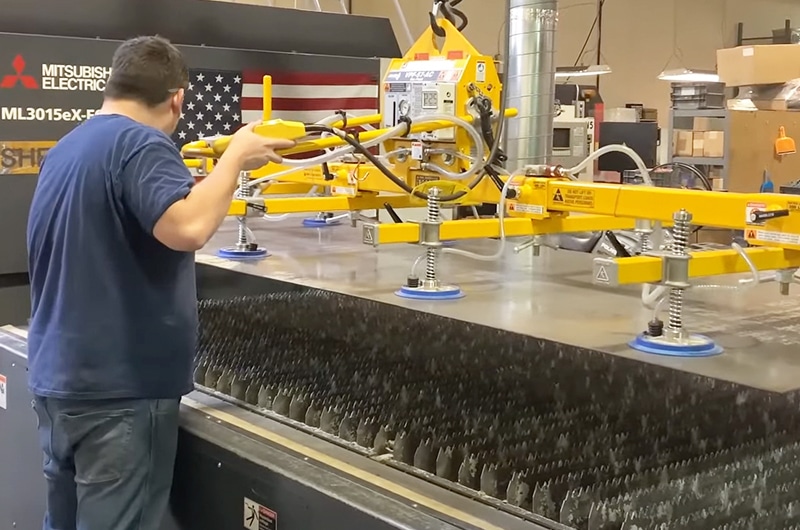

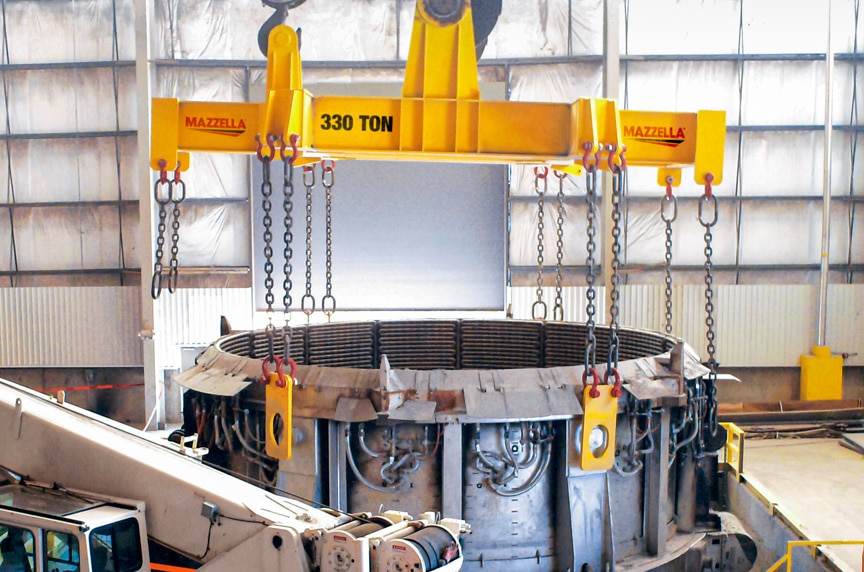

Based on years of repairing, rebuilding, and manufacturing BTH devices at Mazzella, there are clear indicators for when repairs make sense and when replacement is the safer and more cost-effective option.

This article will walk you through the major factors that determine whether your device is repairable, what drives costs, how lifecycle affects your decision, and what to know before you send anything in.

Table of Contents

- What Causes Below-the-Hook Devices to Fail?

- What Makes Below-the-Hook Devices Non-Repairable?

- What Can Be Repaired on a BTH Device?

- The Hidden Costs of Repairing a BTH Lifting Device

- Does Repairing a BTH Device Costs More Than Replacing?

- How Lifecycle and Service Class Affect the Repair vs Replace Decision

- What to Do Before You Send Your BTH Device

- How Mazzella Helps You Choose Between Repair or Replace

- Frequently Asked Questions

What Causes Below-the-Hook Devices to Fail?

Most repair or replacement decisions start with understanding what caused the failure. In the field, Mazzella sees the same issues repeatedly.

Overload

This happens when a device is used to lift more than its rated capacity. Overload events can damage structural members, bend hooks, stretch components, or silently introduce metal fatigue that cannot be seen by the naked eye.

Misuse

Misuse includes:

- Using the device in an application it was not designed for

- Loading the device at angles or in directions it was not engineered to handle

- Modifying or adapting the device in ways that change its load path

Neglect

Devices left outside or exposed to the elements can accumulate rust, lose lubrication, or develop pitting and corrosion that weakens its structure.

Normal Wear and Tear

Even well-maintained devices eventually wear down through repeated use. Common wear areas include pin holes, bail connections, hooks, and hinge points.

Knowing what caused the damage helps determine if the device can be safely repaired.

What Makes Below-the-Hook Devices Non-Repairable?

Not every damaged BTH lifter can be repaired. Some conditions automatically move you toward replacement.

Missing or Incorrect ASME B30.20 Tag

If the lifter is missing its required identification tag and the original documentation cannot be verified, Mazzella cannot legally or safely repair it. This includes devices without:

- Manufacturer name

- Serial number

- Capacity

- Design category

- Service class

Without a valid tag or documentation, the origin and design of the lifter cannot be confirmed.

No Documentation

If the tag is missing but the customer still has:

- Approval drawings

- Manuals

- Purchase records

- Engineering documentation

Mazzella can often trace it back to a reputable manufacturer. Without these, the device cannot be returned to service.

Our team often comes across homemade BTH devices that have neither documentation nor tags. We will not repair these types of devices.

Catastrophic Overload

If the device has been:

- Significantly bent

- Crushed

- Torn apart

- Visibly deformed

- Subjected to known overload far above capacity

It is no longer safe to trust the metal. Even if some parts look undamaged, the entire device may have been overstressed.

Severe Deformation or Compromised Structure

If the device looks like a pile of scrap metal, it should be treated like one. Repairs in these conditions often cost more than replacement and carry unacceptable risk.

End-of-Life Devices with Unknown Lift Cycles

Devices manufactured before the BTH-1 standard went into effect in 2008 often lack service class and design category ratings. These legacy devices may be approaching or well past their intended lifecycle.

What Can Be Repaired on a BTH Device?

Many issues are still repairable if the device has proper documentation and has not been overloaded.

Common repairs include:

- Wear in pin holes

- Bale wear

- Hinge repairs

- Replacement of hooks or mechanical components

- Surface preparation and repainting

- Structural repairs on minor damage

In some misuse scenarios, a single component may fail while the rest of the lifter remains structurally sound. Mazzella will still perform a full engineering evaluation to ensure the entire device is safe before recommending repair.

The Hidden Costs of Repairing a BTH Lifting Device

Those who send a BTH device in for repairs are often surprised by the cost. Inspections are not free, and before you send a device in, you should understand the costs associated with the process.

Labor Costs

Employees will be tasked with:

- Receiving and storing the device

- Tearing down components as needed

- Measuring and evaluating structural members

- Performing a thorough engineering review

- Providing a formal repair quote

Complex devices will also require significantly more time and labor.

Engineering Time

If the device was not manufactured by Mazzella, engineers must reverse-engineer dimensions and load paths to redesign replacement parts.

Material and Machining

Repairs may require:

- Custom machining

- Specialty steel

- Replacement hardware

- Precision fitting and welding

Shipping Costs and Storage Fees

Large lifters can cost several thousand dollars to ship both ways. This is often the hidden factor that pushes a repair over the cost of a replacement. You should also keep this in mind when purchasing new BTH devices.

When a device is sent in, it takes up valuable floor space in the shop. Long-term storage may incur a fee or require the customer to pick up the device.

Does Repairing a BTH Device Costs More Than Replacing?

There is a practical and financial point when replacement becomes the smarter option.

If the cost of a repair reaches approximately 75 percent of the cost of a new device, Mazzella will quote both options. This allows the customer to make the best decision based on:

- Remaining lifecycle

- Condition of the device

- Future service needs

A severely neglected device may have a long list of repairs. Once the number of issues and repair points grows, labor hours multiply.

Additionally, cutting apart large structural components and rebuilding them from scratch takes far more labor than assembling new components.

Heavy and Older Devices

The larger and heavier the lifter, the higher the freight bill. This can turn a simple repair into an expensive project.

Devices built before 2008 that lack service class and design category information are often near the end of their intended life. Replacing them is usually the safer long-term choice.

How Lifecycle and Service Class Affect the Repair vs Replace Decision

Every lifting device has a finite service life based on their design category, service class, and estimated number of lift cycles. Even when a device looks fine externally, metal fatigue may be accumulating.

Most facilities do not track individual lifts. The standard uses approximate lifts per day to determine what service class is needed. If you know the age of the lifter, the number of shifts, and approximate lifts per shift, you can calculate the BTH device’s remaining life.

If a device is old enough to be near the top of its lift cycle range, showing signs of wear, missing documentation, or in a critical workflow with high usage, replacement is often the safer long-term investment.

What to Do Before You Send Your BTH Device

You can save time and money by doing a few things before shipping a device in.

1. Send Photos of Device

Share clear photos of the damaged areas of the device, identification tags, and side and top views. These images will allow the engineers to determine if repair is even possible and prepare ahead of time.

2. Provide Context, and Have Clear Answers

Share what happened with your contact.

How did the damage occur? Do you think the device was overloaded? How old is the device, and when was it inspected last? How often do you use it?

3. Gather Documentation

Example of documentation include:

- Approval drawings

- Manuals

- Purchase information

4. Request an On-site Assessment

A Mazzella representative can often determine viability without requiring you to ship the device.

How Mazzella Helps You Choose Between Repair or Replace

Mazzella is equipped to help you make the safest and most cost-effective decision.

We can:

- Review photos before anything is shipped

- Perform detailed engineering inspections

- Provide repair and replacement quotes side-by-side

- Offer recommendations based on safety, lifecycle, and cost

- Redesign or upgrade older devices to improve performance and usability

Reach out to one of our experts to learn more about your options.

Frequently Asked Questions

Copyright 2025. Mazzella Companies.