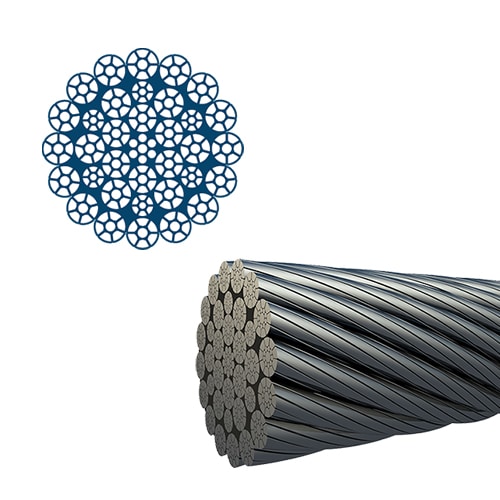

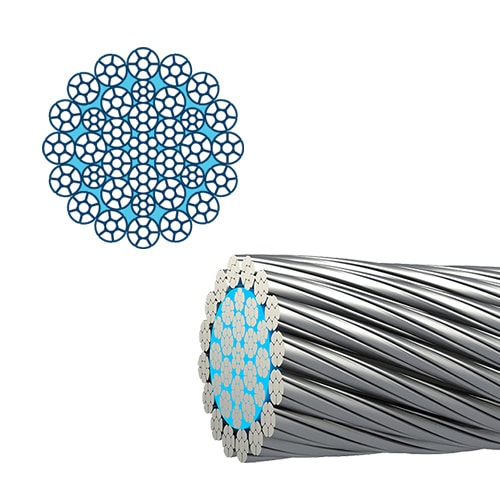

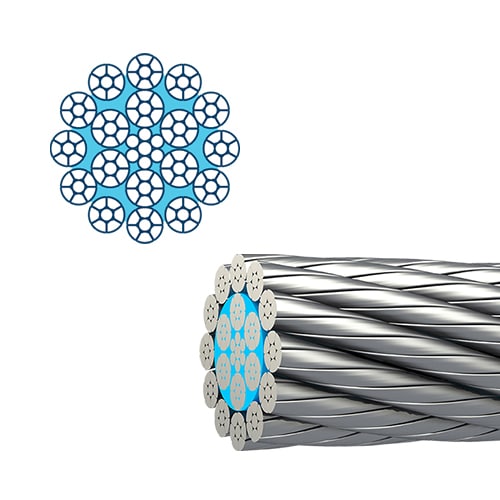

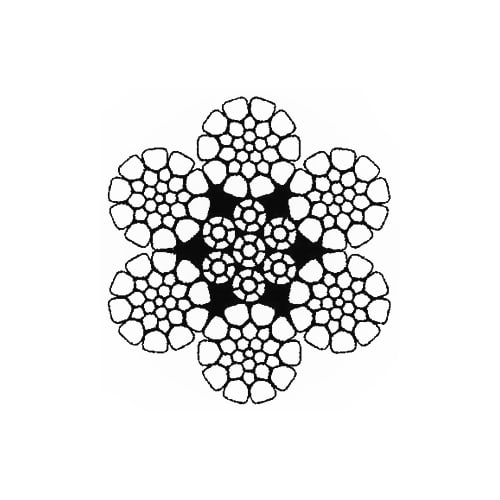

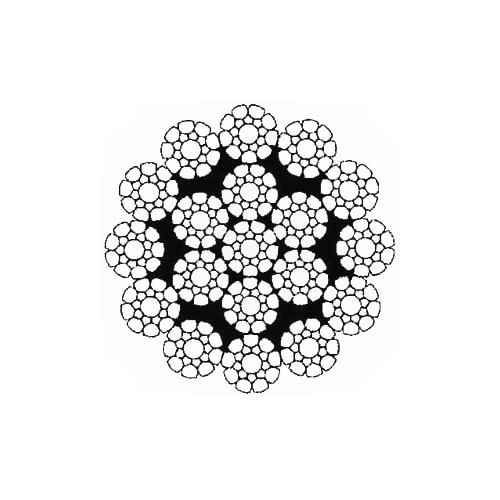

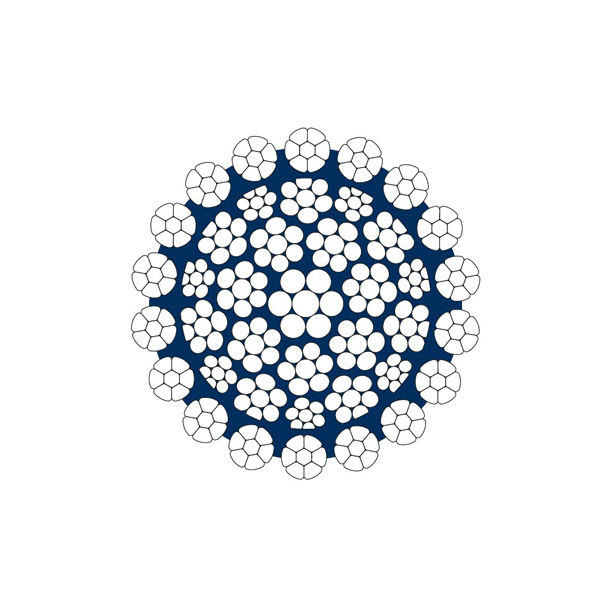

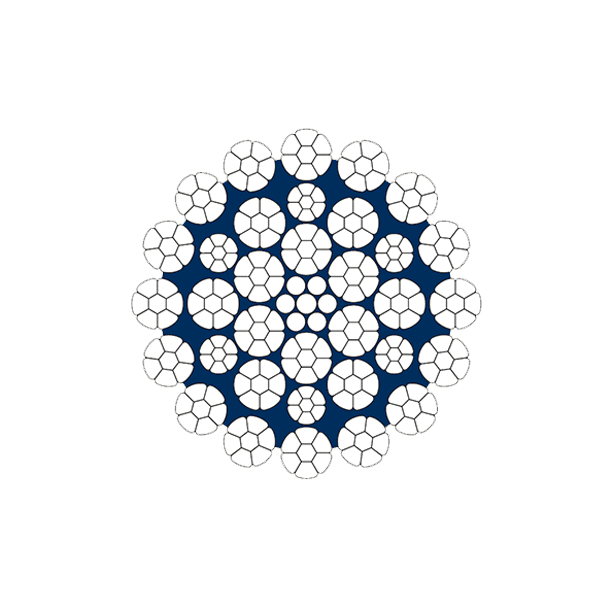

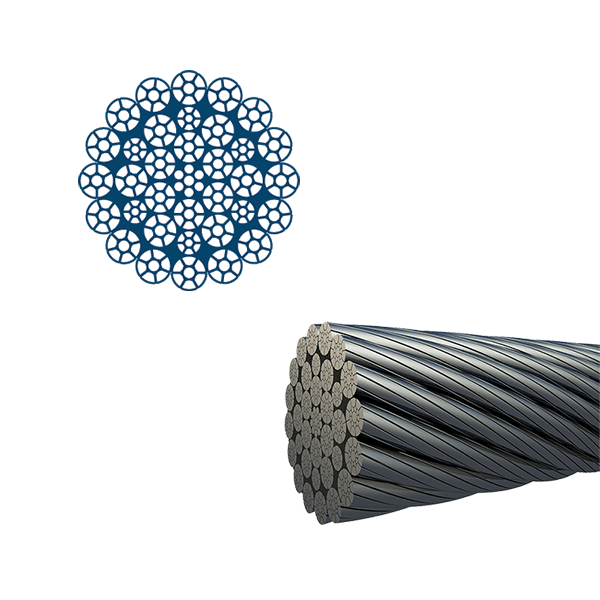

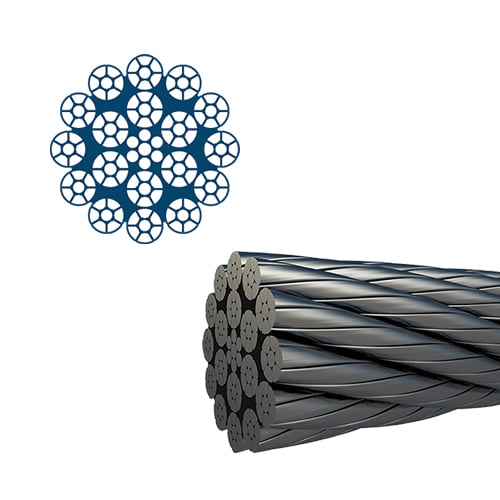

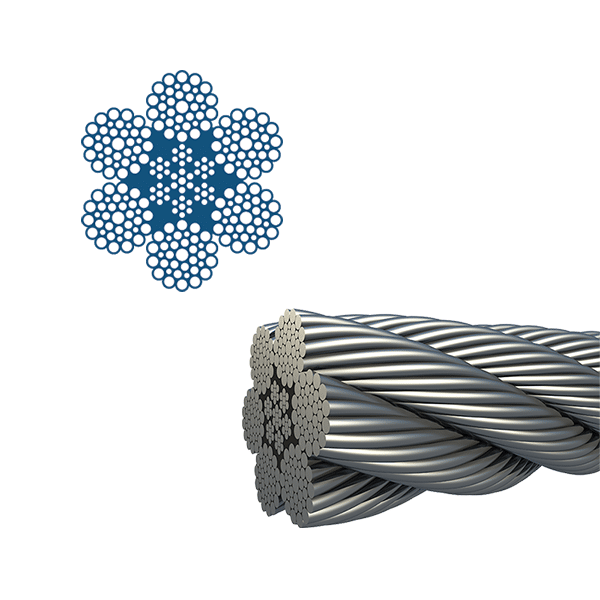

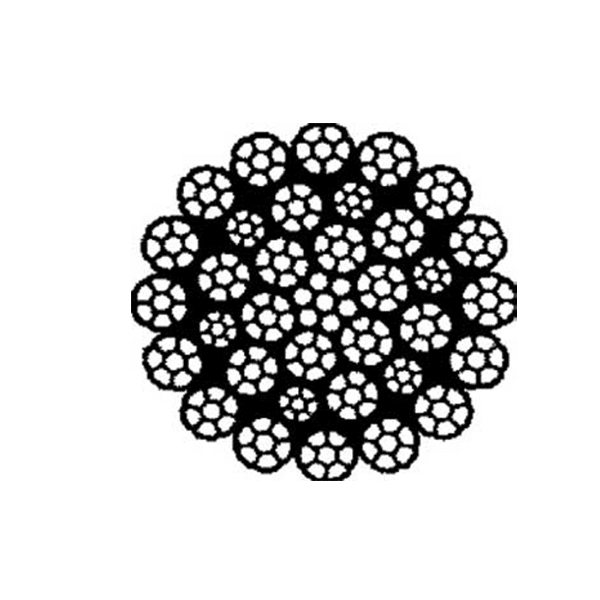

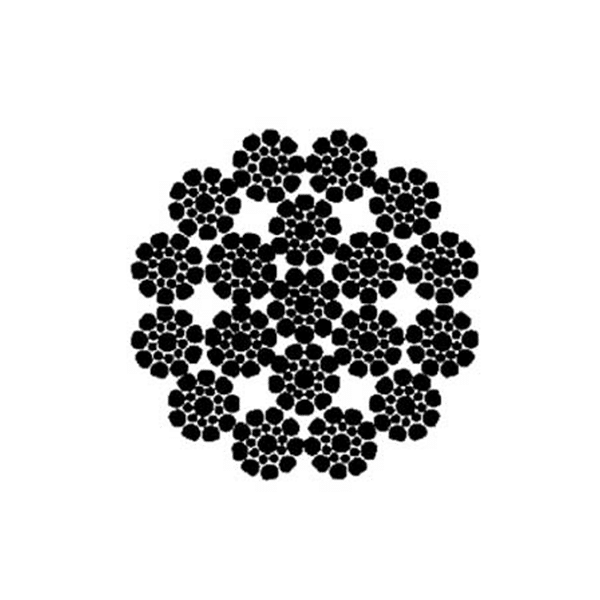

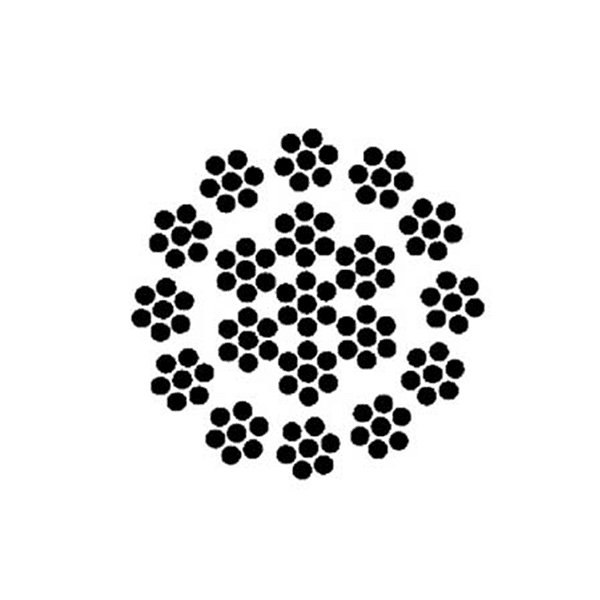

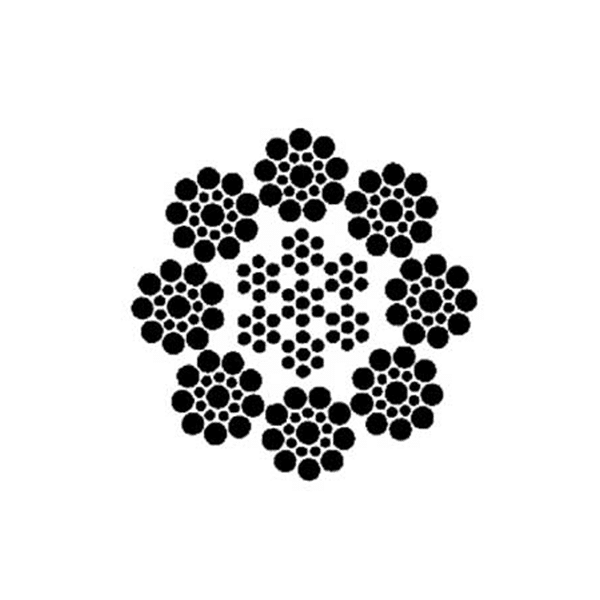

Rotation Resistant

We stock a wide variety of rotation resistant wire ropes from several manufacturers.Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.Call us at 800.362.4601 or click here to get the rotation resistant wire rope you need!

Still Have Questions?

Connect with our specialist today! We will help you answer any questions you may have and assist you in completing your project.