![How Much Does Lifting and Rigging Training Cost? [Complete Breakdown for 2025]](https://www.mazzellacompanies.com/wp-content/uploads/2025/08/20250820_MAZ_Cost-of-Training_Hero.jpg)

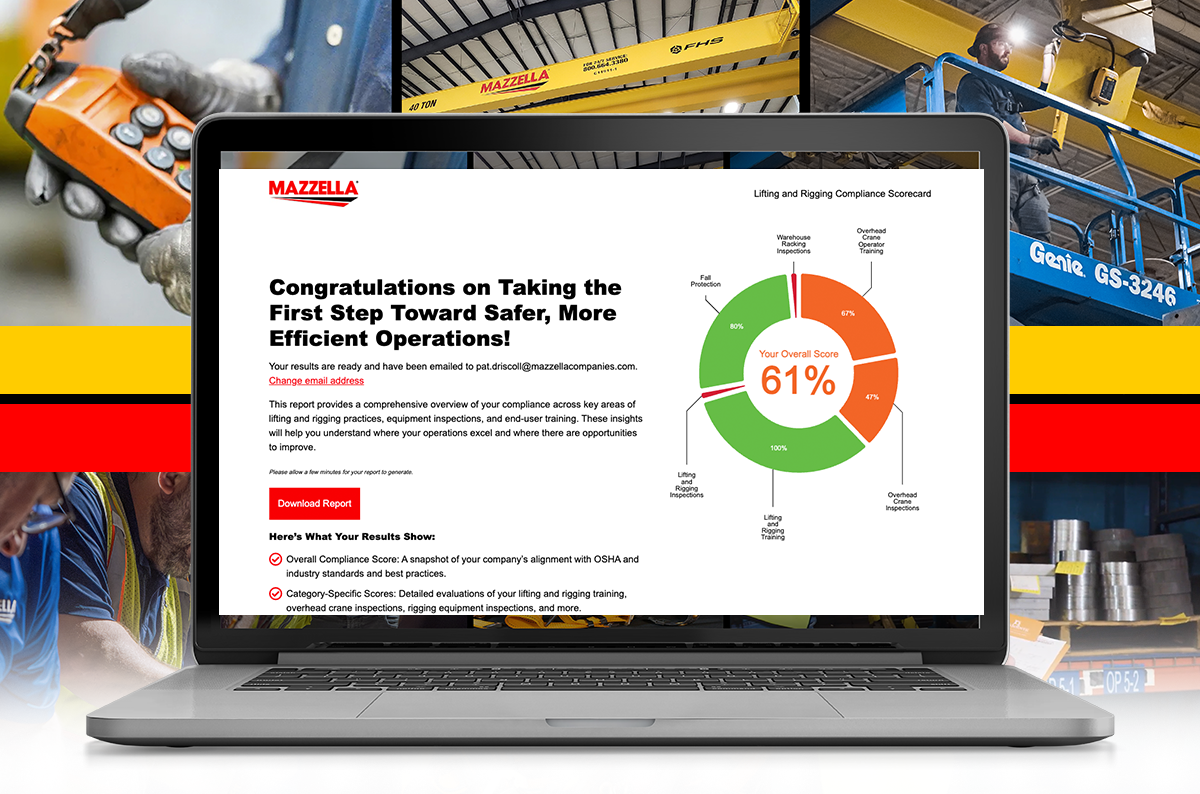

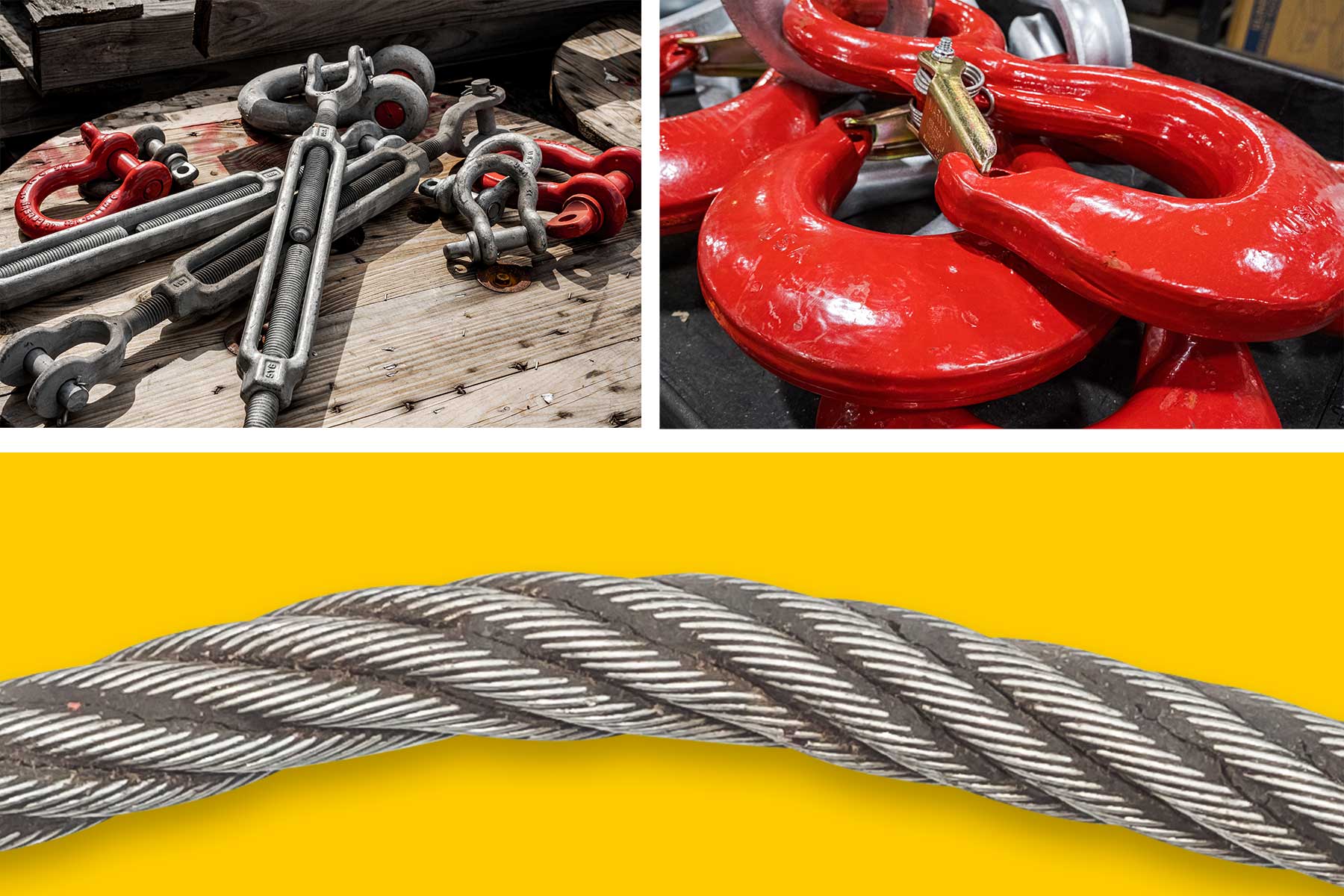

OSHA and ASME Compliance

Learn more about the applicable standards that relate to the lifting and rigging industries, including: ASME, OSHA, CMAA, ANSI, NEC, and more. You’ll learn about how you can make your lifting and rigging programs compliant, and how often you should be inspecting crane and hoist equipment, as well as rigging equipment like slings and hardware.