How Are Drones Being Used for Overhead Crane Inspections?

Can a drone be used in overhead crane inspections? The simple answer is yes, but before using a drone, be sure to understand what you’re getting from a third-party inspection company.

“Technology, like art, is a soaring exercise of the human imagination.”

The words of late American sociologist, writer and Harvard professor Daniel Bell apply to many fields that are embracing technology more and more each day. That list includes the lifting and rigging industry, as technological advances have made work safer and more efficient in recent years.

For nearly a century, the United States military has utilized drone technology, and over the last decade, it has taken off as a personal hobby. Now, crane service technicians are using it to make their work more efficient and safer.

From conducting basic inspections of overhead cranes with regular cameras or using thermal equipment, drones have helped minimize safety risks for workers and downtime for manufacturing plants.

In this article, we look at the following questions:

- How are drones being used in the lifting and rigging industry?

- Why are drones becoming more commonplace in the industry?

- How important is safety with drone usage?

- How long have drones been used in crane inspections?

- Where else has this technology been used for inspections?

- What should you look for in a third-party inspection company?

How Are Drones Being Used in the Lifting and Rigging Industry?

Drone operators use regular cameras to conduct visual inspections of the crane itself and of the runway.

With certain overhead crane systems, drone operators are able to go into places that would be difficult for inspectors in a scissor lift. The drones can go behind certain runway beams and reach spots where you would think, “There’s no way I could fly an expensive drone in there to conduct an inspection.”

Why Are Drones Becoming More Commonplace in the Lifting and Rigging Industry?

It may not be easy for a crane service technician to go into the air to conduct an inspection. Also, doing so requires taking your crane out of production for what could be an hours-long stretch as the problems are being diagnosed.

However, if you’ve already established your baseline inspection and / or thermal readings, the drone can be sent up to inspect the overhead crane. Then, the results can be compared to the baseline to see if problems exist. One of the biggest bonuses is you don’t even have to stop the crane from working because the drone can go wherever it needs to as long as you have a competent pilot.

From a safety standpoint, using a drone minimizes the amount of time a service technician is put in harm’s way by conducting preventative maintenance or typical inspection at height. You save time and maintain productivity, and the technicians remain as safe as possible while working on the cranes.

When using a drone, if the technician does notice a problem, then they can predictively schedule that work. This will allow the crane to be taken out of service without negatively impacting productivity.

How Important is Safety with Drone Usage?

It’s important to understand drones aren’t always the right fit for overhead crane inspections.

There will be times when crane service technicians need to go into the air to inspect a crane or runway. This is because drones aren’t able to see everything. However, those times when technicians need to go into the air can be scheduled. Drones limit the number of times technicians need to go into the air. They help take the technicians out of harm’s way, and instead, can spend time performing other functions throughout the workday.

When you do the scheduled work, the plant’s usually down, and in that case, you’ve got multiple people working at height. When you have a crew of people working at height, you can all look out for each other while the plant or mill is down. If that plant is operational during the inspection or service, the technician being up in the air by themselves could have catastrophic results.

How Long Have Drones Been Used in Crane Inspections?

About a year before the onset of the COVID-19 pandemic, companies began experimenting with using drones in overhead crane inspections.

These companies began displaying their technological advances at crane symposiums and other trade shows. One company in particular did a demonstration by flying its drone over the event. In flying the drone over the symposium, the operator was able to show conference attendees on a big-screen television what was being looked for.

Currently, steel mills are using drone technology for portions of their plants. Now, nine times out of 10, plants do their inspections with the drone. It is done by a third-party company or someone in-house who is trained.

After spending four-plus years working on overhead cranes and overhead crane structures, drone companies have started to incorporate thermal cameras into their machines. With the thermal cameras, companies can look at hotspots on the crane motors, including:

- Bearings

- Sheaves

- Drums

- Anything mechanical where it’s rotating could create a hotspot and a potential problem.

Doing so sets a baseline for these potential hotspots that can help crane operators set up an acceptable range of operation. This allows you to do future inspections and identify when problems arise based on temperature readings.

Where Else Have Drones Been Used in Steel Mills?

Along with overhead cranes and runways, operators have used drones to examine other places within steel mills.

Drones have been used to view and inspect exhaust and filtration systems. Additionally, they have been used to fly over the furnace and see what is going on inside. This helps if you don’t already have cameras focused on the furnaces.

Also, drones are used to examine the super structure and outside areas, including:

- Cooling towers

- Exhaust systems

- House systems

- Conveyors

In addition to steel mills, drone technology has been used in other industries, most notably:

- Pulp factories

- Paper factories

- Power plants

What Should You Look for in a Third-Party Inspection Company?

Finding the right third-party inspection company can be easier said than done.

Price should never be the only determining factor used when deciding whether to choose one company over another. You want to consider the following factors when choosing a third-party inspection company:

- What training does the drone operator have?

- Is the operator licensed to fly their drone?

- How much experience does the operator have in factory environments?

Also, you should check references of third-party companies. This will allow you to see what kind of work they’ve done before, as well as how their clients felt about the service.

The key to a successful drone inspection is having a good pilot.

Mazzella Lifting Specialists have seen the results of a bad pilot firsthand. On one recent inspection, our specialist watched a pilot crash a drone into a crane. That operator panicked when the drone struck the crane. However, rather than regrouping quickly and keeping the drone in flight, the operator let it crash to the ground, which made it inoperable.

While at this particular steel plant, our specialist said, “Oh man, that guy’s going to be in trouble.” The drone operator’s supervisor said in response, “You don’t know the half of it. You know how much the drones cost? They’re expensive, and it had the thermal camera on it.”

What Types of Inspections Should Be Done on an Overhead Crane?

Buying an overhead crane comes with one cost, but keeping it in operational condition comes with another.

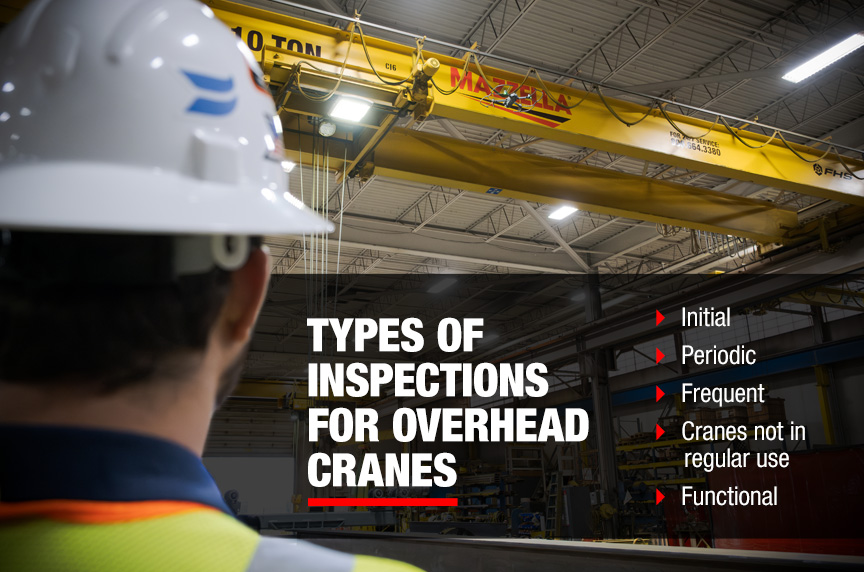

Throughout its lifespan, your overhead crane will need to be inspected. According to ASME B30.2 Overhead and Gantry Cranes, there are five types of inspections required for overhead cranes:

- Initial

- Periodic

- Frequent

- Cranes not in regular use

- Functional

Initial Inspection

An initial inspection is a visual and audible examination of the crane.

New, reinstalled, altered, repaired, and modified equipment shall be inspected prior to initial use to verify compliance with the applicable provisions of Chapter 2-1.* Inspection of altered, repaired, and modified cranes may be limited to the parts of the crane affected by the alteration, repair, or modification, as determined by a qualified person.

Records of the inspection and test shall be made.

*-Chapter 2-1 covers the General Construction and Installation of Overhead and Gantry Cranes.

Periodic Inspection

Like the initial inspection, a periodic inspection is a visual and audible examination of the crane. According to the ASME B30.2 standard, equipment shall be inspected at intervals dependent on the use of the equipment as follows:

- Normal service — yearly

- Heavy service — yearly

- Severe service — quarterly

Frequent Inspection

A frequent inspection is a visual and audible examination of the crane. According to ASME B30.2, equipment shall be inspected at intervals dependent on the use of the equipment as follows:

- Normal service — monthly

- Heavy service — weekly to monthly

- Severe service — daily to weekly

Records of the inspection should be made.

Cranes Not in Regular Use

A crane that has been idle for a period of one month or more, but less than one year, shall be inspected before being placed in service in accordance with the requirements listed in para. 2-2.1.4.*

A crane that has been idle for a period of one year or more shall be inspected before being placed in service in accordance with the requirements listed in para. 2-2.1.5**.

*-Paragraph 2-2.1.4 outlines all components that need to be examined during a Frequent Inspection.

**-Paragraph 2-2.1.5 outlines what needs to be examined during a Periodic Inspection.

Functional Inspection

A functional test inspection is a visual and audible operational examination of the crane and shall be conducted at the beginning of each shift or before the crane is first used during each shift. In special applications, where the suspended load is transferred from operator to operator at shift change, the functional test inspection shall be performed when that lift is completed.

Records of the inspection should be made.

How Can Mazzella Help You with Your Overhead Cranes?

If the results of your drone crane inspection reveals the need for service, and in more difficult circumstances, a replacement, Mazzella has many ways in which to help you.

Overhead Crane Manufacturing

Mazzella is a leading manufacturer of world-class overhead cranes with nearly 70 years of experience. We engineer and build custom solutions ranging from light-duty, economical cranes up to large capacity, high-duty cycle cranes with welded plate-box girders.

Mazzella provides all types of overhead crane systems, including, but not limited to:

- Bridge cranes

- Gantry cranes

- Workstation cranes

- Jib cranes

- Monorail cranes

We have on-staff engineering and computer-aided design (SolidWorks) capabilities to build customized indoor cranes and runway systems to a lifting capacity in excess of 150 tons.

Our work is done in full compliance with standards from the CMAA (Crane Manufacturers Association of America, Inc.), NEC (the National Electrical Code), OSHA (Occupational Safety and Health Administration) and ASME (American Society of Mechanical Engineers). We have extensive electrical / control engineering capabilities, as well as AWS certified welders (AWS D1.1 and D14.1).

Crane Service

Additionally, we are an industry leader in hoist and overhead crane services. Our highly trained service staff specializes in solving complex problems in emergency situations. We find creative solutions to even the most challenging overhead crane service requirements. Our personalized approach to overhead crane and hoist maintenance is just one of the many benefits of our service team.

Mazzella strives to minimize your downtime. Our phones are answered 24 hours a day, 7 days a week, and we work on all makes and models of cranes and hoists. Mazzella has over 100 full-time technicians ready to answer the call at a moment’s notice.

Each of our trucks has a scissor lift, diagnostic equipment, tools and many of the parts that your crane or hoist needs to get back up and running. We carry VFDs (variable frequency drives), radio controls, contractors and much more!

Other Services

At Mazzella, we have you covered when it comes to all of your lifting and rigging needs. With our ready stock inventory, we offer all industries a variety of lifting and rigging devices, including a complete selection of:

- Wire rope

- Lifting slings

- Rigging hardware

- Hoists

- Fall protection

Whether you’re an existing customer or a new customer, Mazzella provides the following value-added and post-sale services:

- Engineering, fabrication, and installation of overhead cranes

- Custom below-the-hook lifting devices

- 24 / 7 emergency crane service, maintenance, and repair

- Overhead crane inspections in compliance with requirements from OSHA, ASME, and CMAA

- Classroom or jobsite rigging training and crane operator training

- Engineered lifelines and personal fall protection equipment

- Rigging inspections in compliance with OSHA and ASME periodic inspection requirements

At Mazzella, we have more than 30 locations across the United States — fully stocked with different sizes and configurations of rigging products for your next project.

Call us at 800.664.3380 or click here if you need to speak with one of our Crane Specialists!

Overhead Hoist & Crane Service

We are an industry leader in hoist and overhead crane services. Our highly trained service staff specializes in solving complex problems in emergency situations. We strive to minimize your downtime. Our phones are answered 24 hours a day, 7 days a week and we work on all makes and models of crane and hoist. Mazzella FHS has over 100 full time technicians ready to answer the call at a moment’s notice.